Simulated biofilm and preparation method and application thereof

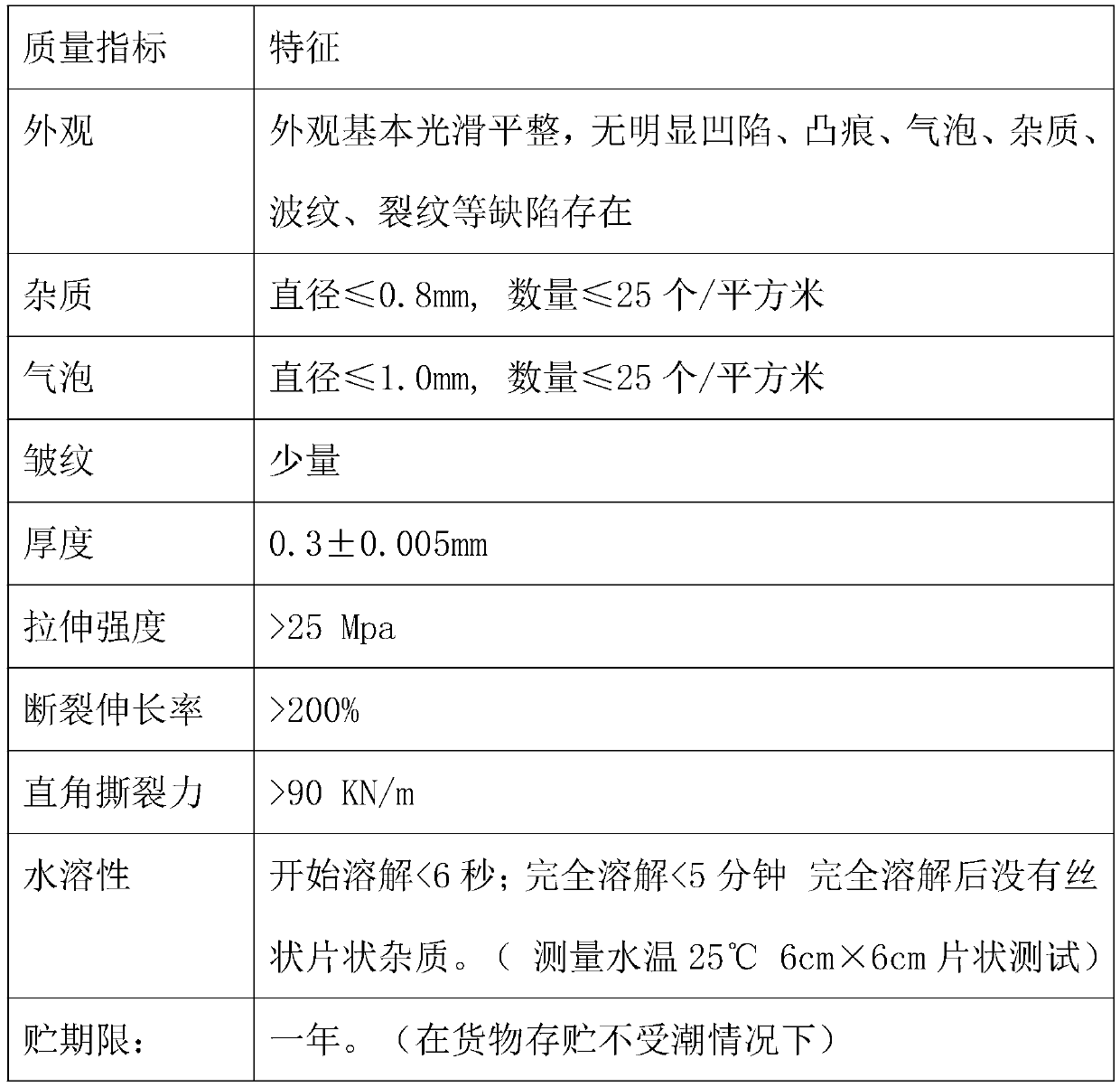

A biofilm and biosurface technology, applied in the field of simulated biofilm and its preparation, can solve the problems of decreased solubility and elongation, and achieve the effects of low cost, excellent tension and tensile strength, and excellent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

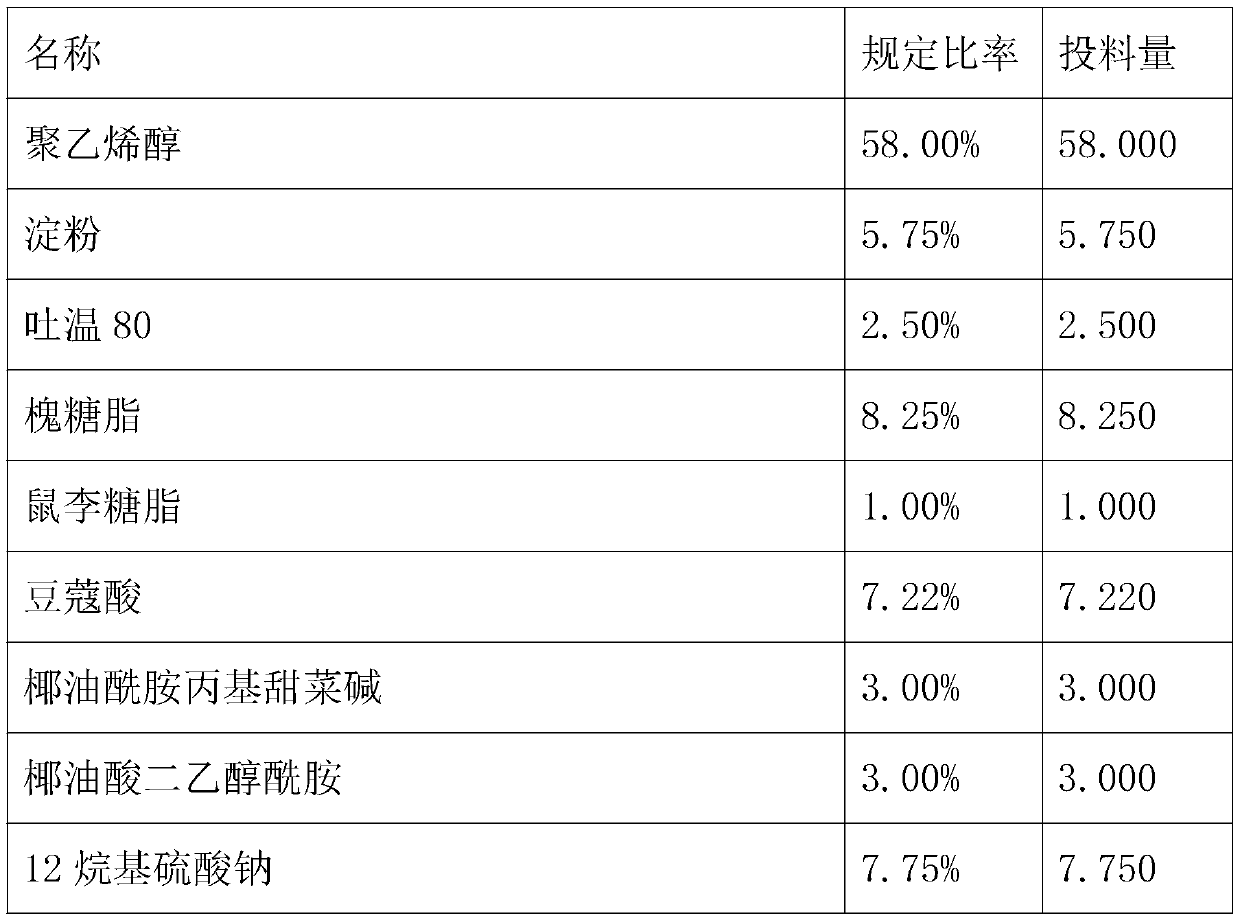

[0048] Embodiment 1 A kind of simulation biofilm, formula comprises the raw material of following percentage:

[0049] Film former 5-90%

[0050] Biosurfactant 1-25%

[0051] Plasticizer 0.1-5%

[0052] Compatibility release agent 0.5-7%

[0053] Water-based preservative 0.1-3%

[0054] Foaming agent 0.5-6%

[0055] Anti-sticking agent 0-5%

[0056] Auxiliary surfactant combination 0-15%

[0057] Active ingredient 0-30%.

[0058] A simulated biological film, the film-forming agent is one or more polymers capable of forming a continuous film; polymers include but are not limited to polyvinyl alcohol PVA, polyethylene oxide, hydroxyethyl cellulose and both one or more combinations. The polyvinyl alcohol adopts partially hydrogenated polyvinyl alcohol, and its film-forming effect is better, and the polyvinyl alcohol with a dynamic viscosity between 3-60 mPa·s (mPa·s) is more suitable for the use of the product of the present invention. The polyvinyl alcohol film-forming ...

Embodiment 2

[0071] Embodiment 2 A kind of simulated biofilm, formula comprises the raw material of following weight portion:

[0072] 72 parts of film forming agent

[0073] Biosurfactant 18 parts

[0074] 4 parts plasticizer

[0075] 1 part anti-sticking agent

[0076] A simulated biological film, the film-forming agent is a combination of polyvinyl alcohol and water-soluble starch with a mass ratio of 11:4.

[0077] A simulated biofilm, the biosurfactant is a combination of sophorolipid and rhamnolipid with a mass ratio of 13:1.

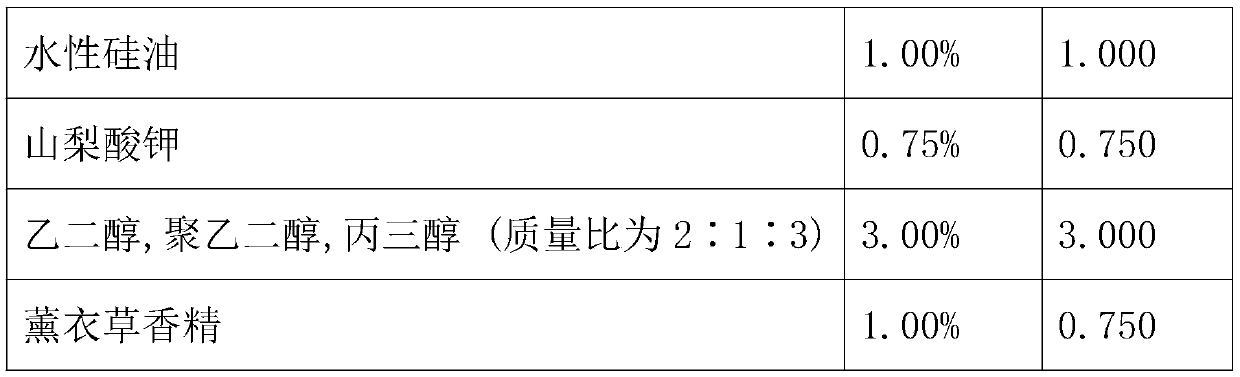

[0078] A simulated biological film, the plasticizer is a combination of ethylene glycol, polyethylene glycol and glycerol, and the mass ratio is 3:1:4.

[0079] A simulated biological film, the anti-sticking agent is a release agent, and the release agent is simethicone.

[0080] A simulated biological film, adding tackifiers, fillers, adhesives, lubricants, other surfactants, preservatives, coloring agents, wetting agents, spices, flavoring agents, penet...

Embodiment 3

[0081] Embodiment 3 A kind of preparation method of simulated biofilm, drying step is completed in two steps:

[0082] (1) The solution is heated from 40°C to 60°C, and the heating time does not exceed 7 minutes;

[0083] (2) In the second step, the solution completed in the first step is heated to 80-90° C., and the heating time is no more than 30 minutes;

[0084] (3) Curing step: the temperature is 20-60° C., the relative humidity is 60-90%, and the water-soluble, fat-soluble or water-fat-soluble glue solution is dried and solidified through a multi-zone drying tunnel.

[0085] A method for preparing a simulated biological film, the water-soluble, fat-soluble or water-fat-compatible glue solution is poured or cast on a substrate, and then enters a drying room to dry and solidify the water-soluble glue solution; the substrate is : Non-woven fiber products or cotton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com