Degradable epoxy resin and preparation method thereof

A technology of epoxy resin and spiral ring structure, which is applied in the field of acid-degradable epoxy resin and its preparation, can solve the problems of environmental pollution, large annual consumption, waste of petroleum resources, etc., and achieve high reactivity and adjustable degradation speed , the effect of fast degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of synthetic method of degradable epoxy resin, comprises the following steps:

[0045] S1: Add 0.5872g (2.77mmol) BTU, 0.3914g (4.16mmol) ethanedithiol and 35.5mg (0.139mmol) benzoin dimethyl ether into the flask, dissolve it with 2.946g tetrahydrofuran, and put it under the ultraviolet lamp (the light intensity is 3000μW / cm 2 ) under irradiation for 3h. Then the product was precipitated with 20 g of ether, and after centrifugation, the obtained product was put into a vacuum drying oven and dried to constant weight.

[0046] S2: Under a nitrogen atmosphere, 0.5748 g (0.22 mmol) of the product of step S1, 1.506 g (13.2 mmol) of allyl glycidyl ether (AGE) and 2.935 g of chloroform were placed in a round bottom flask. Then under ultraviolet light (light intensity is 3000μW / cm 2) under reaction for 3h. Precipitate three times in 20 g of ether, obtain the product after centrifugation, put it into a vacuum drying oven and dry to constant weight to obtain a degradab...

Embodiment 2

[0051] A kind of synthetic method of degradable epoxy resin, comprises the following steps:

[0052] S1: Add 0.5869g (2.77mmol) of BTU, 1.304g (13.85mmol) of ethanedithiol and 4.7mg (0.028mmol) of azobisisobutyronitrile into the flask, and dissolve them with 11.741g of 1,4-dioxane Dissolved and reacted at 80°C for 6h. The product was precipitated with 30 g of ether, and after centrifugation, the product was placed in a vacuum drying oven to constant weight.

[0053] S2: Under a nitrogen atmosphere, 0.6527g (0.39mmol) of the product of step S1, 90mg (0.78mmol) of AGE and 2.957g of chloroform were placed in a round bottom furnace. Then under ultraviolet light (light intensity is 9000μW / cm 2 ) under reaction for 1h. Precipitate three times in 20 g of ether, obtain the product after centrifugation, put it into a vacuum drying oven and dry to constant weight to obtain a degradable epoxy resin.

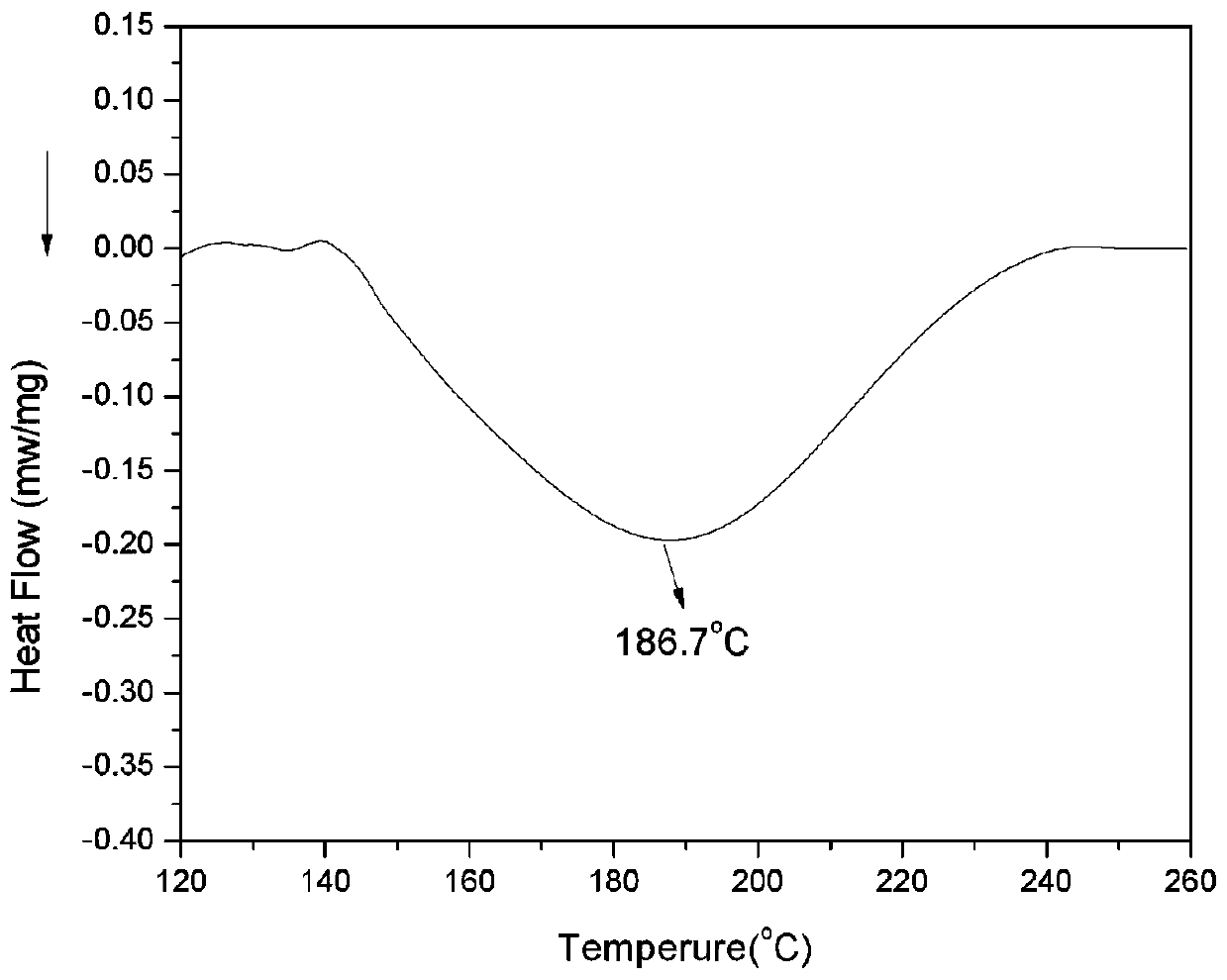

[0054] The structure of embodiment 2 product has been characterized with infrared s...

Embodiment 3

[0058] A kind of synthetic method of degradable epoxy resin, comprises the following steps:

[0059] S1: Add 0.5303g (2.50mmol) BTU, 0.5437g (5.0mmol) 1,3-propanedithiol and 13mg (0.05mmol) azobisisoheptanonitrile into the flask, and use 5.31g N,N-dimethyl It was dissolved in formamide and reacted at 60°C for 24h. The product was precipitated with 64 g of diethyl ether, and after centrifugation, the product was put into a vacuum drying oven to constant weight.

[0060] S2: Under an argon atmosphere, 0.4185 g (0.20 mmol) of the product of step S1, 0.228 g (2.0 mmol) of AGE and 3.073 g of chloroform were placed in a round bottom flask. Then under ultraviolet light (light intensity is 6000μW / cm 2 ) under reaction for 2.5h. Precipitate three times in 57g ether, obtain the product after centrifugation, put it into a vacuum drying oven and dry to constant weight to obtain a degradable epoxy resin.

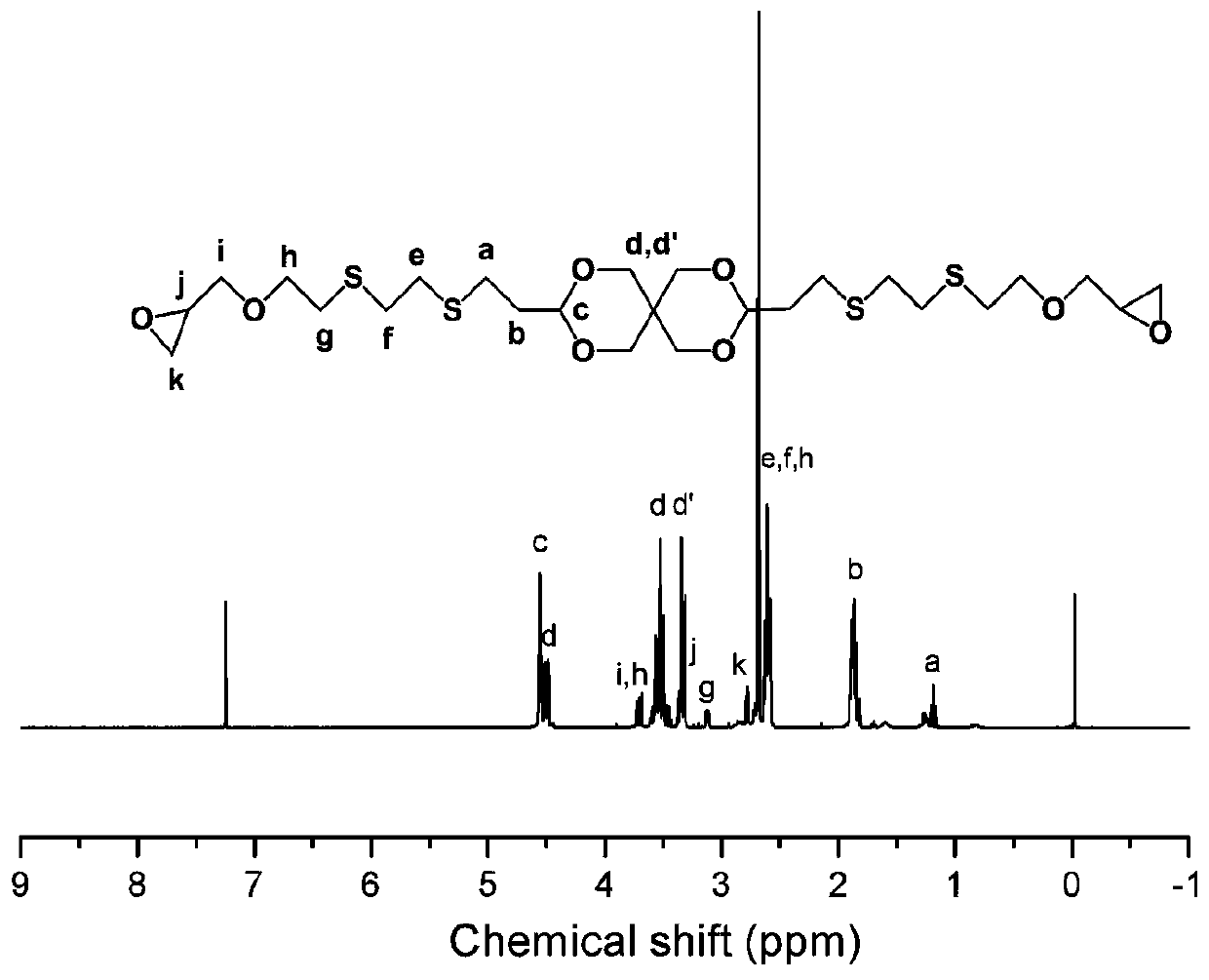

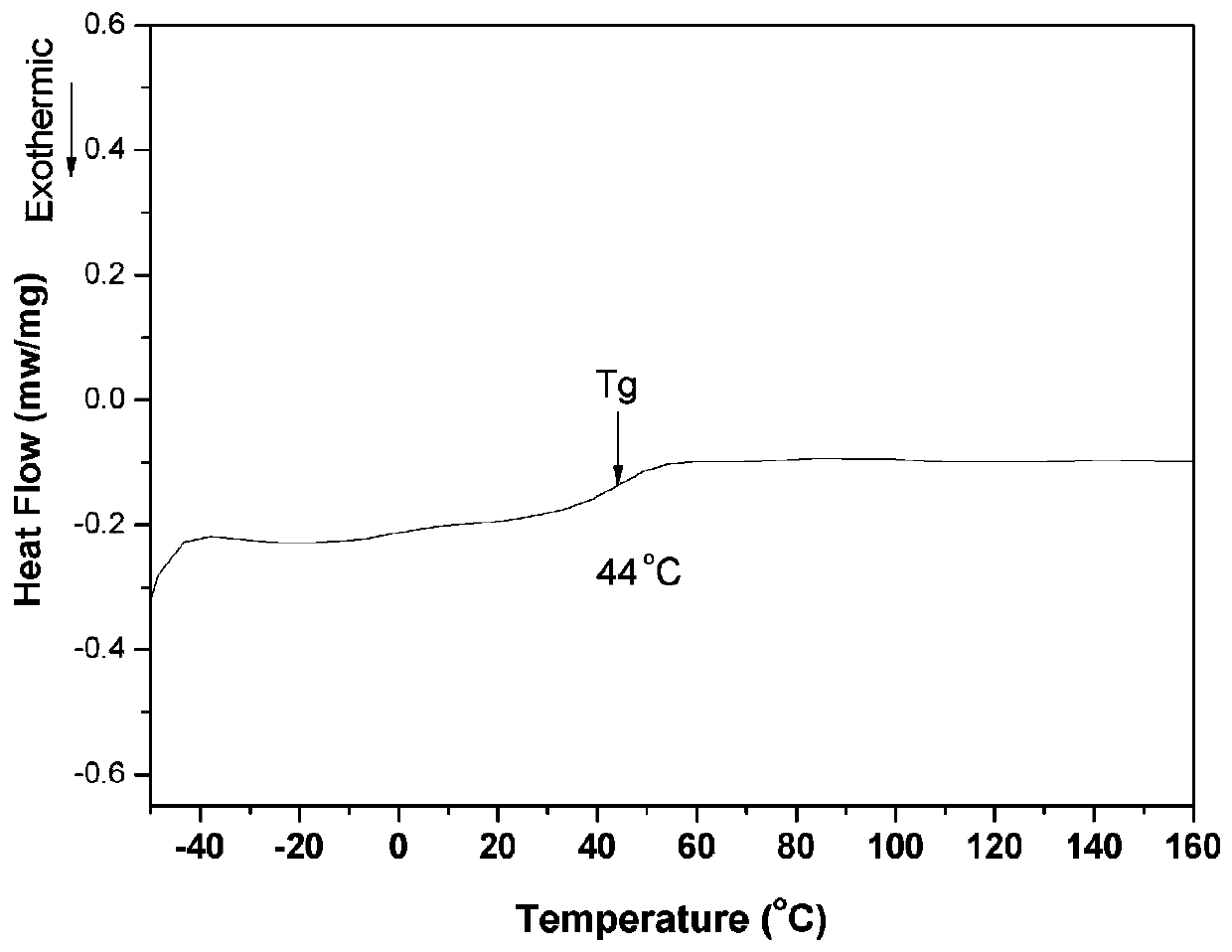

[0061] The structure of embodiment 3 product uses 1 Characterized by H NMR, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com