A reusable large-size hollow adsorbent and its preparation method and application

An adsorbent and hollow technology, which is applied in the field of large-size hollow adsorbent and its preparation, can solve the problems of low yield, uneven shrinkage, easy cracking, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

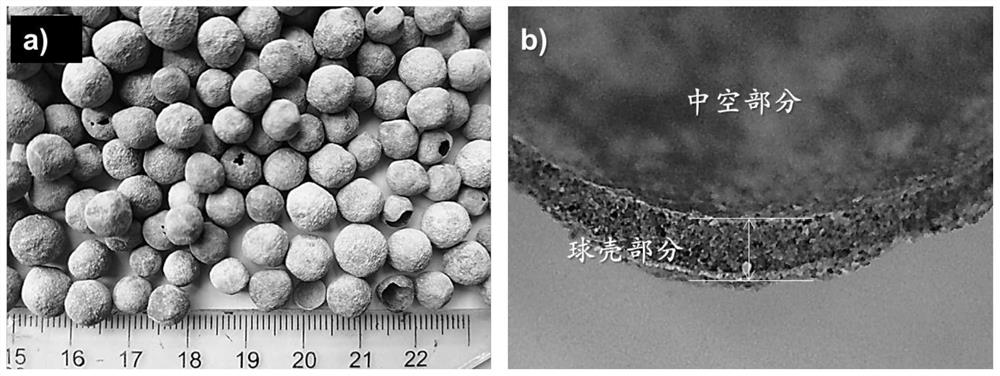

[0042] A method for preparing a hollow adsorbent with a particle size of 8-10 mm and a hollow pore size of 3-5 mm in this embodiment is as follows:

[0043] (1) Weigh 1kg of ordinary Portland cement and dry it at about 100°C, and make the powder pass through a 200-mesh sieve for later use;

[0044] (2) Weigh 500g of urea pellets (3-5mm in particle size), and add it into the ball machine; start the ball machine, use the aqueous solution of 0.5wt% CMC as binder, and spray it on the urea particle surface;

[0045] (3) Gradually add the above-mentioned dried and sieved cement powder, repeat the steps of spraying binder and adding cement powder until the ball diameter of most of the samples reaches 8mm, and use a mesh screen to screen out 8-10mm particles ;

[0046] (4) Carry out the standard curing 24h in the standard curing box for the above-mentioned obtained sample;

[0047] (5) Soak the cured sample particles in water, dissolve the urea spherical core completely by repeated...

Embodiment 2

[0049] A preparation method of a hollow adsorbent with a particle diameter of 5-8 mm and a hollow pore diameter of 2-3 mm in this embodiment is as follows:

[0050] (1) Weigh 1kg of gypsum powder and dry it at about 100°C, and make the powder pass through a 200-mesh sieve for later use;

[0051] (2) take by weighing the compound fertilizer pellet (2-3mm of particle diameter) of 500g, and it is added in the ball machine; Start into ball machine, be binding agent with the aqueous solution of 0.5wt% guar gum, and It is sprayed on the surface of urea particles;

[0052] (3) Gradually add the above-mentioned dried and sieved gypsum powder, repeat the steps of spraying binder and adding cement powder until the ball diameter of most samples reaches 5mm, and use a mesh screen to screen out 5-8mm particles ;

[0053] (4) Carry out the standard curing 24h in the standard curing box for the above-mentioned obtained sample;

[0054] (5) Soak the cured sample particles in water, and dis...

Embodiment 3

[0056] A method for preparing a hollow adsorbent with a particle size of 8-10 mm and a hollow pore size of 3-5 mm in this embodiment is as follows:

[0057] (1) Weigh 1kg of ordinary Portland cement and dry it at about 100°C, and make the powder pass through a 200-mesh sieve for later use;

[0058] (2) take by weighing the polystyrene pellet (particle diameter 3-5mm) of 20g, and it is added in the ball machine; Start into ball machine, with the aqueous solution of 1.0wt% polyvinyl alcohol as binding agent, and It is sprayed on the surface of polystyrene particles;

[0059] (3) Gradually add the above-mentioned dried and sieved cement powder, repeat the steps of spraying binder and adding cement powder until the ball diameter of most of the samples reaches 8mm, and use a mesh screen to screen out 8-10mm particles ;

[0060] (4) Carry out the standard curing 24h in the standard curing box for the above-mentioned obtained sample;

[0061] (5) Soak the cured sample particles in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com