A process for making acid

A process and acid mist technology, applied in the preparation of sugar derivatives, catalyst activation/preparation, separation methods, etc., can solve the problems of large footprint, incomplete reaction, easy pollution, etc., to solve environmental problems and complete chemical reactions , the effect of turning waste into treasure safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

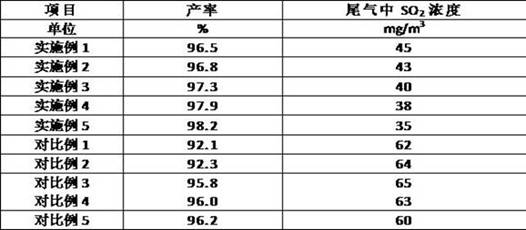

Examples

Embodiment 1

[0036] A kind of acid production process is characterized in that, comprises the steps:

[0037] Step S1, waste acid treatment: the waste sulfuric acid by-product of the refinery is atomized to form acid mist by using a combination of high-pressure pump conveying mechanical atomization and compressed air assisted atomization; the quality of the waste sulfuric acid is 100%. The sub-concentration is 80%; the particle size of the acid mist is 60um.

[0038] Step S2, treatment of sulfur-containing minerals: pulverize the sulfur-containing minerals, then use a detergent to clean them in an ultrasonic cleaner at 40-50°C for 1-2 hours, rinse them with water, and dry them at 80°C until they reach a constant weight; The sulfur-containing mineral is pyrite;

[0039] Step S3, preparation of mixed furnace gas: the sulfur-containing minerals produced in step S2 are oxidized and burned to obtain furnace gas, which is cooled and dusted in turn, and then passed through an empty tower, a pack...

Embodiment 2

[0047] A kind of acid production process is characterized in that, comprises the steps:

[0048] Step S1, waste acid treatment: the waste sulfuric acid by-product of the refinery is atomized to form acid mist by using a combination of high-pressure pump conveying mechanical atomization and compressed air assisted atomization;

[0049] Step S2, treatment of sulfur-containing minerals: pulverize the sulfur-containing minerals, and then use a detergent to clean them in an ultrasonic cleaner at 42°C for 1.2 hours, rinse them with water, and dry them at 83°C until they reach a constant weight;

[0050] Step S3, preparation of mixed furnace gas: the sulfur-containing minerals produced in step S2 are oxidized and burned to obtain furnace gas, which is cooled and dusted in turn, and then passed through an empty tower, a packed tower, a dynamic wave scrubber and an electric furnace gas in sequence. Demister, purify high-concentration sulfur-containing gas; and mix the obtained high-con...

Embodiment 3

[0062] A kind of acid production process is characterized in that, comprises the steps:

[0063] Step S1, waste acid treatment: the waste sulfuric acid by-product of the refinery is atomized to form acid mist by using a combination of high-pressure pump conveying mechanical atomization and compressed air assisted atomization;

[0064] Step S2, treatment of sulfur-containing minerals: pulverize the sulfur-containing minerals, and then use a detergent to clean them in an ultrasonic cleaner at 45°C for 1.5 hours, rinse them with water, and dry them at 85°C until they reach a constant weight;

[0065] Step S3, preparation of mixed furnace gas: the sulfur-containing minerals produced in step S2 are oxidized and burned to obtain furnace gas, which is cooled and dusted in turn, and then passed through an empty tower, a packed tower, a dynamic wave scrubber and an electric furnace gas in sequence. Demister, purify high-concentration sulfur-containing gas; and mix the obtained high-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com