N and P co-doped carbon aerogel and preparation method and application thereof

A technology of carbon aerogel and co-doping, applied in chemical instruments and methods, manufacturing of hybrid/electric double layer capacitors, inorganic chemistry, etc., can solve problems such as low specific capacitance and complicated preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of N, P co-doped carbon aerogel, comprising the following steps:

[0025] Pretreating the biomass fibers with a pretreatment liquid containing sodium hypochlorite, glacial acetic acid, water and ethanol, mixing the obtained pretreated fibers with water, and performing fiber opening treatment to obtain a water-biomass fiber suspension;

[0026] The water-biomass fiber suspension was mixed with NH 4 h 2 PO 4 Freeze molding after mixing to obtain N, P co-doped cellulose airgel;

[0027] The N and P co-doped cellulose aerogels are sequentially subjected to carbonization treatment and activation treatment to obtain N and P co-doped carbon aerogels.

[0028] The invention adopts the pretreatment liquid containing sodium hypochlorite, glacial acetic acid, water and ethanol to pretreat the biomass fiber, mixes the obtained pretreated fiber with water, and performs fiber opening treatment to obtain the water-biomass fiber su...

Embodiment 1

[0041] Mix 1g of cattail fiber, 1g of sodium hypochlorite, 0.2mL of glacial acetic acid, 100mL of water and 100mL of ethanol, stir at 400rpm for 1h, then add 1g of sodium hypochlorite and 0.2mL of glacial acetic acid, and continue stirring for 1h; The obtained solid material is washed to neutrality to obtain pretreated fibers; the pretreated fibers are mixed with water, and the cell ultrasonic breaker is used to sonicate for 15 minutes under the condition of 1000W ultrasonic power to obtain a water-typha fiber suspension with a mass concentration of 0.8% ;

[0042] By water - cattail fiber suspension and NH 4 h 2 PO 4 The mass ratio is 1:2, the water-typha fiber suspension and NH 4 h 2 PO 4 Mixing, and then freezing and forming (the temperature is -50°C, the time is 80h), to obtain N, P co-doped cellulose airgel;

[0043] Put the N, P co-doped cellulose airgel into a tube furnace, and carry out carbonization treatment under the protection of nitrogen, the nitrogen flow r...

Embodiment 2

[0045] Mix 7g of kapok fiber, 7g of sodium hypochlorite, 0.5mL of glacial acetic acid, 350mL of water and 350mL of ethanol, stir at 500rpm for 1h, then add 7g of sodium hypochlorite and 0.5mL of glacial acetic acid, and continue stirring for 1h; The obtained solid material was washed to neutrality to obtain pretreated fibers; the pretreated fibers were mixed with water, and the cell ultrasonic breaker was used to sonicate for 13 minutes under the condition of 1200W ultrasonic power to obtain a water-kapok fiber suspension with a mass concentration of 0.8% ;

[0046] By water - kapok fiber suspension and NH 4 h 2 PO 4 The mass ratio is 1:1, the water-kapok fiber suspension and NH 4 h 2 PO 4 Mixing, and then freezing and molding (at a temperature of -50°C and a time of 72 hours) to obtain N and P co-doped cellulose airgel;

[0047] Put the N, P co-doped cellulose airgel into a tube furnace, and carry out carbonization treatment under the protection of nitrogen, the nitroge...

PUM

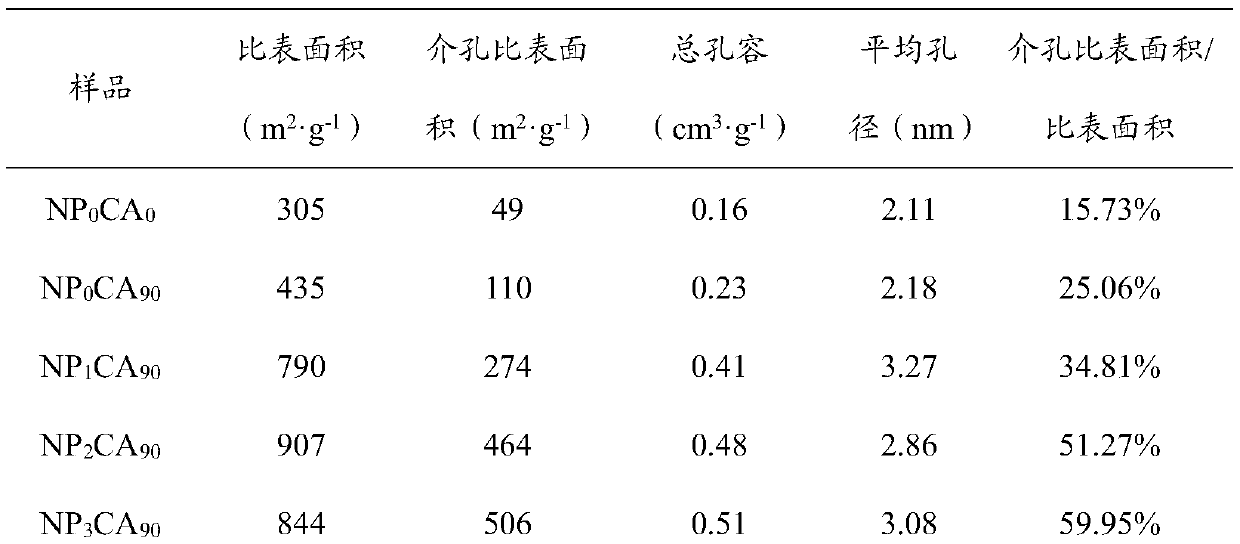

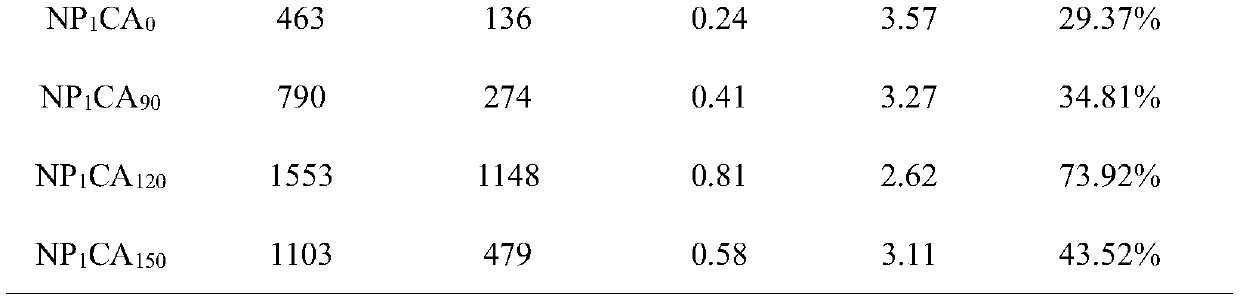

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com