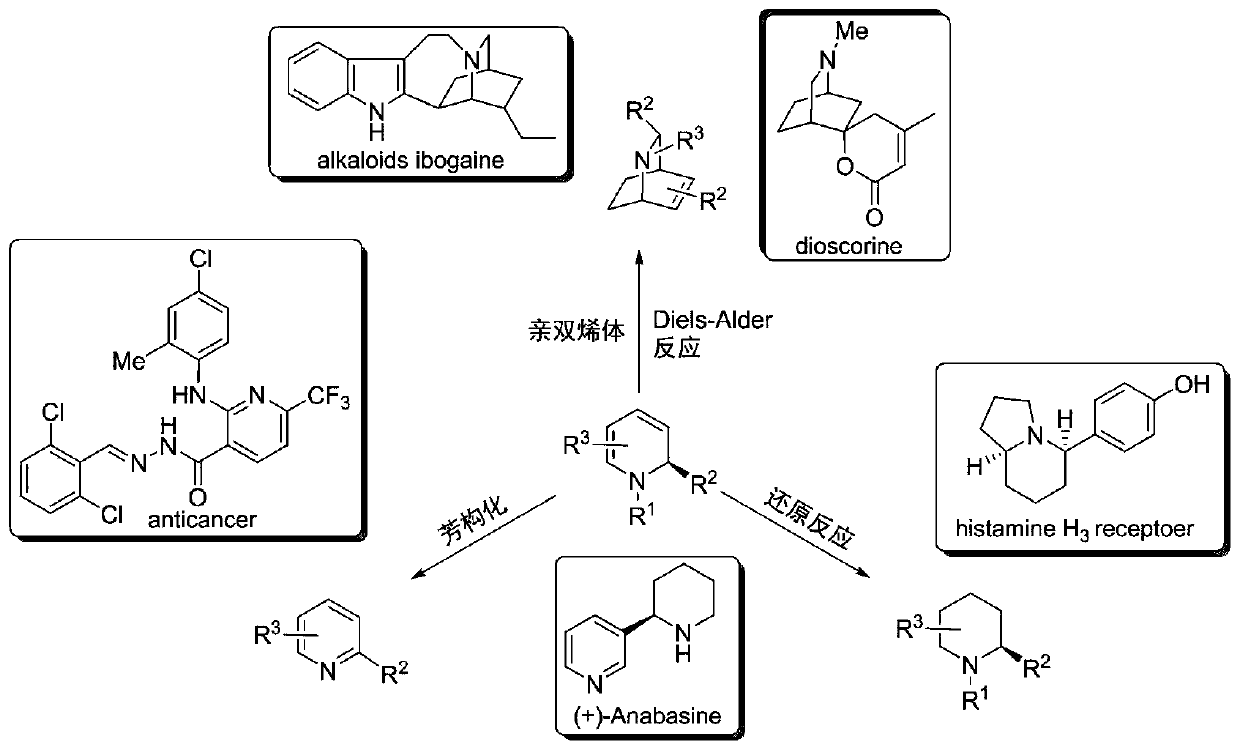

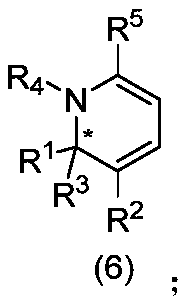

Chiral 1,2-dihydropyridine compound as well as preparation method and application thereof

A technology for dihydropyridine and aldehyde compounds, applied in the direction of organic chemistry, etc., can solve the problems of reduced applicability of synthetic methods, difficult synthesis, and poor reaction universality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

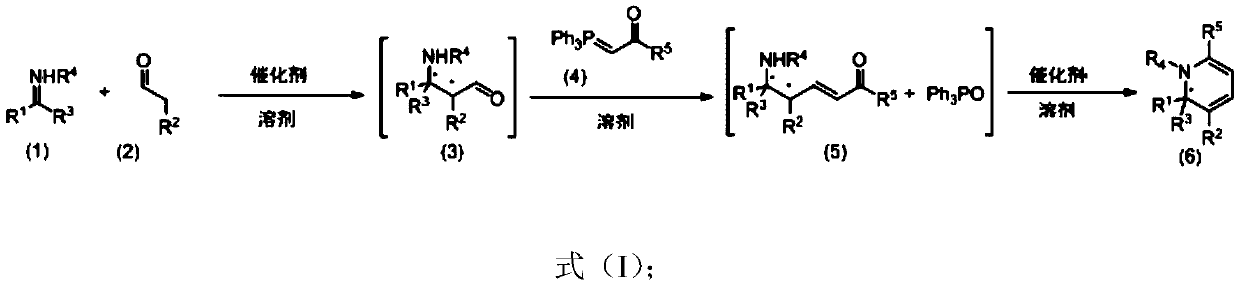

Method used

Image

Examples

Embodiment 1

[0162]

[0163]Under nitrogen protection, add imine 1a (410mg, 2.0mmol), propionaldehyde 2a (348mg, 6mmol) and dry redistilled acetonitrile (15mL) into a 25mL Schlenk tube, then stir at 0°C for 12h, a white solid Precipitation, acetonitrile and excess propionaldehyde 2a were removed by rotary evaporation. The white solid crude intermediate was transferred to a 10 mL Schlenk sealed tube, added dry redistilled ethyl acetate (6 mL), ylide 4a (636 mg, 2 mmol), and stirred at 80° C. for 12 h. Return to room temperature, add SiCl under nitrogen protection 4 (72μL, 0.6mmol), react at 40°C for 5h. The system was returned to room temperature, and the reaction solution was slowly added dropwise to 0°C saturated sodium bicarbonate solution (20 mL) to quench the reaction, extracted with ethyl acetate (3×15 mL), the organic phases were combined, and dried over anhydrous sodium sulfate. Column chromatography, eluent (petroleum ether / diethyl ether=20:1). Compound 6a was obtained as a c...

Embodiment 2

[0165]

[0166] Under nitrogen protection, add imine 1a (410mg, 2.0mmol), propionaldehyde 2a (348mg, 6mmol) and dry redistilled acetonitrile (15mL) into a 25mL Schlenk tube, then stir at 0°C for 12h, a white solid Precipitation, acetonitrile and excess propionaldehyde 2a were removed by rotary evaporation. The white solid crude intermediate was transferred to a 10 mL Schlenk sealed tube, dry redistilled dichloromethane (6 mL) and ylide 4b (664 mg, 2 mmol) were added, and stirred at 80° C. for 12 h. Return to room temperature, add SiCl under nitrogen protection 4 (48μL, 0.4mmol), react at 40°C for 8h. The system was returned to room temperature, and the reaction solution was slowly added dropwise to 0°C saturated sodium bicarbonate solution (20 mL) to quench the reaction, extracted with ethyl acetate (3×15 mL), the organic phases were combined, and dried over anhydrous sodium sulfate. Column chromatography, eluent (petroleum ether / diethyl ether=20:1). The colorless oily c...

Embodiment 3

[0168]

[0169] Under nitrogen protection, add imine 1a (422mg, 2.0mmol), propionaldehyde 2a (348mg, 6mmol) and dry redistilled acetonitrile (15mL) into a 25mL Schlenk tube, then stir at 0°C for 12h, a white solid Precipitation, acetonitrile and excess propionaldehyde 2a were removed by rotary evaporation. The white solid crude intermediate was transferred to a 10 mL Schlenk-sealed tube, added dry redistilled ethyl acetate (6 mL), ylide 4a (636 mg, 2 mmol), and stirred at 90° C. for 12 h. Return to room temperature, add SiCl under nitrogen protection 4 (72μL, 0.6mmol), react at 30°C for 5h. The system was returned to room temperature, and the reaction solution was slowly added dropwise to 0°C saturated sodium bicarbonate solution (20 mL) to quench the reaction, extracted with ethyl acetate (3×15 mL), the organic phases were combined, and dried over anhydrous sodium sulfate. Column chromatography, eluent (petroleum ether / diethyl ether=20:1). The colorless oily compound 6c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com