A high-sensitivity large-area laser ultrasound imaging method

A technology of laser ultrasound and imaging methods, which is applied in the fields of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and material analysis through optical means, and can solve the problems of huge total data volume, optical or acoustic Problems such as increased reflection loss and high processing difficulty achieve the effect of simple image reconstruction algorithm, reduced multiple reflection attenuation, and fast data acquisition and transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

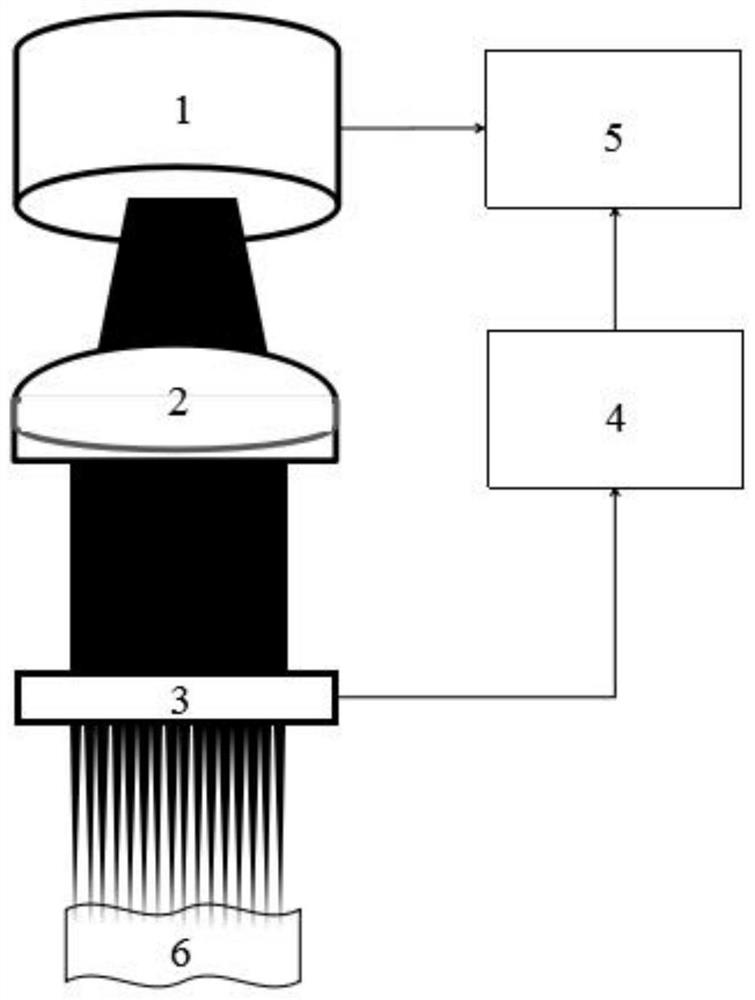

[0028] Example 1: See figure 1 ,like figure 1 A high-sensitivity large-area laser ultrasonic imaging system shown includes 1. a light source, 2. a collimator lens, 3. a microlens array, 4. a signal preprocessing module, 5. a computer, and 6. a sample to be tested.

[0029] A collimating lens 2 and a microlens array 3 are placed in sequence directly under the light source 1 ; the measured sample 6 is placed under the microlens array 3 .

[0030] The microlens array 3 , the signal preprocessing module 4 and the computer 5 are electrically connected in sequence; the light source 1 and the computer 5 are electrically connected in sequence.

[0031] Further, the light source 1 is a wavelength-tunable OPO laser (GWU, model versaScan / 120), with an optical pulse width of 10 ns, an operating wavelength of 410-2500 nm, and a maximum single pulse energy of 30 mJ; the array size of the microlens array 3 is 10mm*10mm, the diameter of the microlens array is 250um, the radius of curvature ...

Embodiment 2

[0034] The structure of this embodiment is similar to that of Embodiment 1, except that the light source 1 is a pulsed laser diode (Laser Components, model 905D4S16C), with an optical pulse width of 100 ns, an operating wavelength of 905 nm, and a peak power of 140 W.

[0035] The present invention also provides a method for imaging using the above-mentioned device, comprising the following steps:

[0036] S1: The light source 1 emits a pulsed or modulated light beam, which is collimated by the collimator lens 2, and then micro-focused and irradiated by the microlens array 3 on the tested sample 6 to generate a laser ultrasonic signal;

[0037] S2: The laser ultrasonic signal is received by each microlens array element of the microlens array 3 in the back mode, and after the signal preprocessing module 4, the extreme value of the laser ultrasonic signal is read and stored in the computer 6 by row and column addressing;

[0038] S3: The extreme value of the laser ultrasonic sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com