Diamine monomer containing tetraphenylethylene-bisarylamine structure, preparation method and application in polyamide synthesis

A technology of tetraphenylethylene and diamine monomers, applied in the field of polyamide, can solve the problems of poor fluorescence effect, limited use range, dark color, etc., to improve transmittance, weaken intermolecular charge transfer, and enhance fluorescence effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

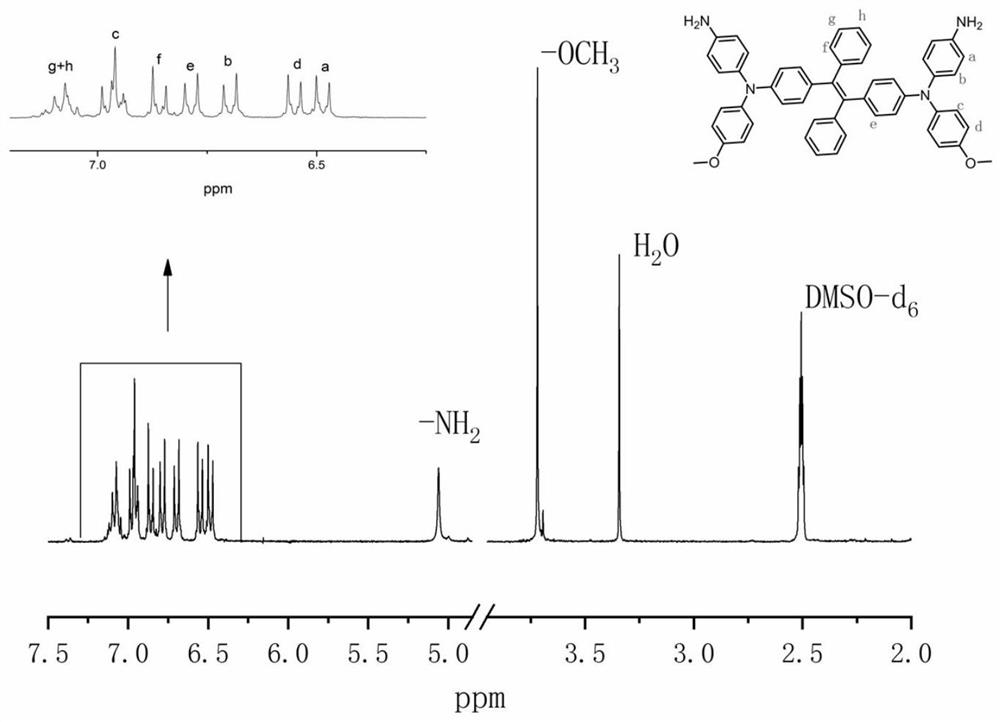

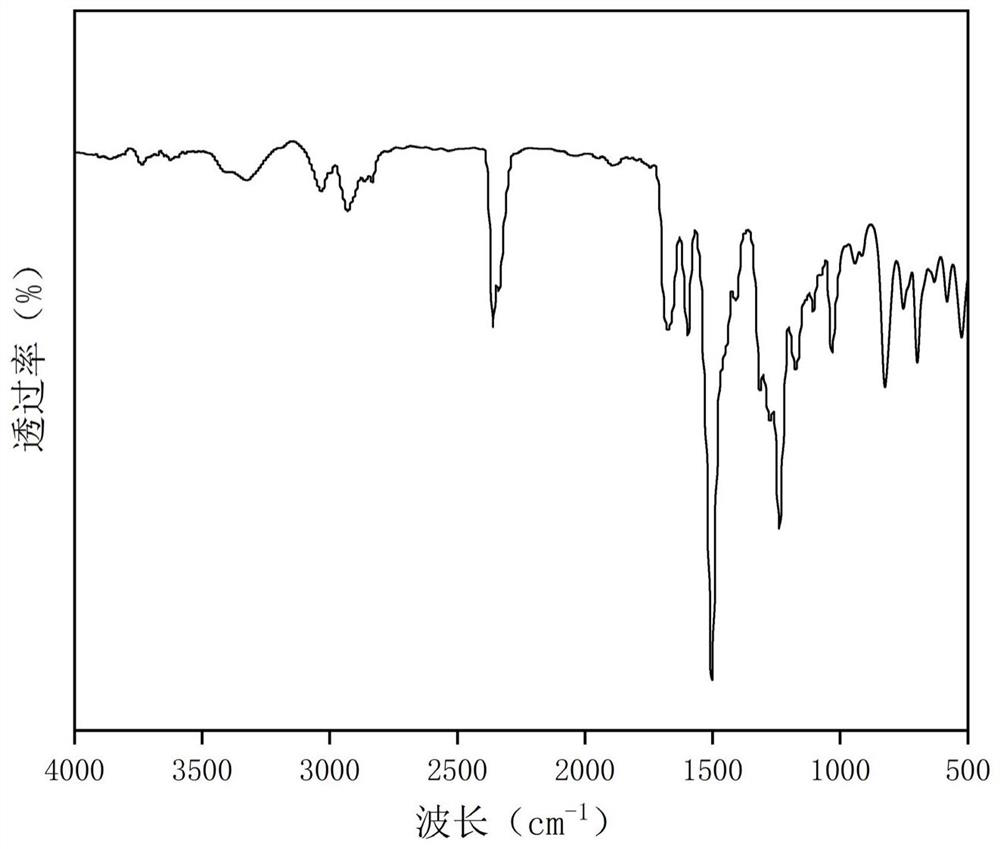

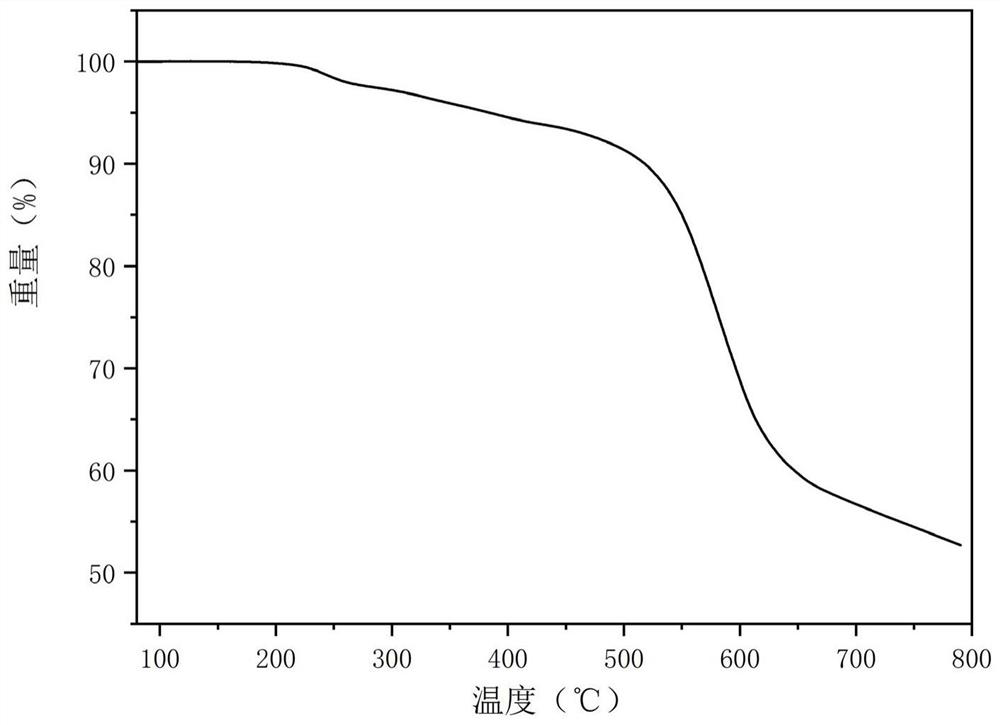

[0041] Example 1: N 1 ,N 1 '-((1,2-cis-diphenylethylene-1,2-)bis(4,1-phenylene)bis(N 1 - Preparation of (4-methoxyphenyl))benzene-1,4-diamine).

[0042] The first step reaction: Add 10-20g of 4-bromobenzophenone and 5-10g of zinc powder into a 1000ml three-necked flask equipped with mechanical stirring, add 500ml of tetrahydrofuran, cool to -78°C, add dropwise 10- 18g of titanium tetrachloride was heated to reflux for 24 hours after returning to room temperature. After the mixture was returned to room temperature, it was quenched with 10% potassium carbonate solution, filtered, and the aqueous layer of the filtrate was extracted three times with ethyl acetate, the organic phases were combined, and the solvent was evaporated. (4-bromophenyl)-1,2-stilbene 12.4g, yield 62%.

[0043] The second step reaction: in a 500m L three-necked flask, add 30-40g p-methoxyaniline, 20-30g p-fluoronitrobenzene, 50-60m L triethylamine and 360m L DMF (DMF is dried with calcium hydride in adva...

Embodiment 2

[0047] Example 2: N 1 ,N 1 '-((1,2-diphenylethylene-1,2-)bis(4,1-phenylene)bis(N 1 Polyamide Preparation by Polymerization of -(4-Methoxyphenyl))Benzene-1,4-diamine)Terephthalic Acid

[0048] In the three-necked flask that magneton, nitrogen inlet and outlet, thermometer are housed, add the 0.3~1g N that embodiment 1 makes 1 ,N 1 '-((1,2-diphenylethylene-1,2-)bis(4,1-phenylene)bis(N 1 -(4-methoxyphenyl))benzene-1,4-diamine) and 0.1~0.5g of terephthalic acid, add 2~5mL of N-methylpyrrolidone, add 1~2mL of triphenyl phosphite ester and 0.5-1mL pyridine, add 0.15-0.30g CaCl2, and react at 110°C for 3-5h under nitrogen atmosphere. After the reaction is completed, cool to room temperature, discharge the material into methanol to obtain a light green fibrous product, reflux wash with ethanol for 30 minutes, wash with water reflux once, reflux with ethanol for 30 minutes, and dry in a vacuum oven at 90°C to obtain terephthalic acid polyamide , The yield is 80-90%.

Embodiment 3

[0049] Example 3: N 1 ,N 1 '-((1,2-diphenylethylene-1,2-)bis(4,1-phenylene)bis(N 1 Polymerization of -(4-methoxyphenyl))benzene-1,4-diamine)-4,4'-biphenyldicarboxylic acid to prepare polyamide

[0050] In the three-necked flask that magneton, nitrogen inlet and outlet, thermometer are housed, add the 0.3~1g N that embodiment 1 makes 1 ,N 1 '-((1,2-diphenylethylene-1,2-)bis(4,1-phenylene)bis(N 1 -(4-methoxyphenyl))benzene-1,4-diamine) and 0.1~0.5g of 4,4'-biphenyldicarboxylic acid, add 2~5mL of N-methylpyrrolidone, add 1~ 2mL triphenyl phosphite and 0.5-1mL pyridine, add 0.15-0.30g CaCl2, and react at 110°C for 3-5h under nitrogen atmosphere. After the reaction is completed, cool to room temperature, discharge the material into methanol to obtain a green powder product, reflux with ethanol for 30 minutes, wash with reflux with water once, and reflux with ethanol for 30 minutes, and dry in a vacuum oven at 90°C to obtain, 4'-biphenyldicarboxylic acid type Polyamide, the yi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com