Lead anode mud and copper anode mud combined treatment method

A technology of copper anode slime and lead anode slime, which is applied in the field of non-ferrous metal smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

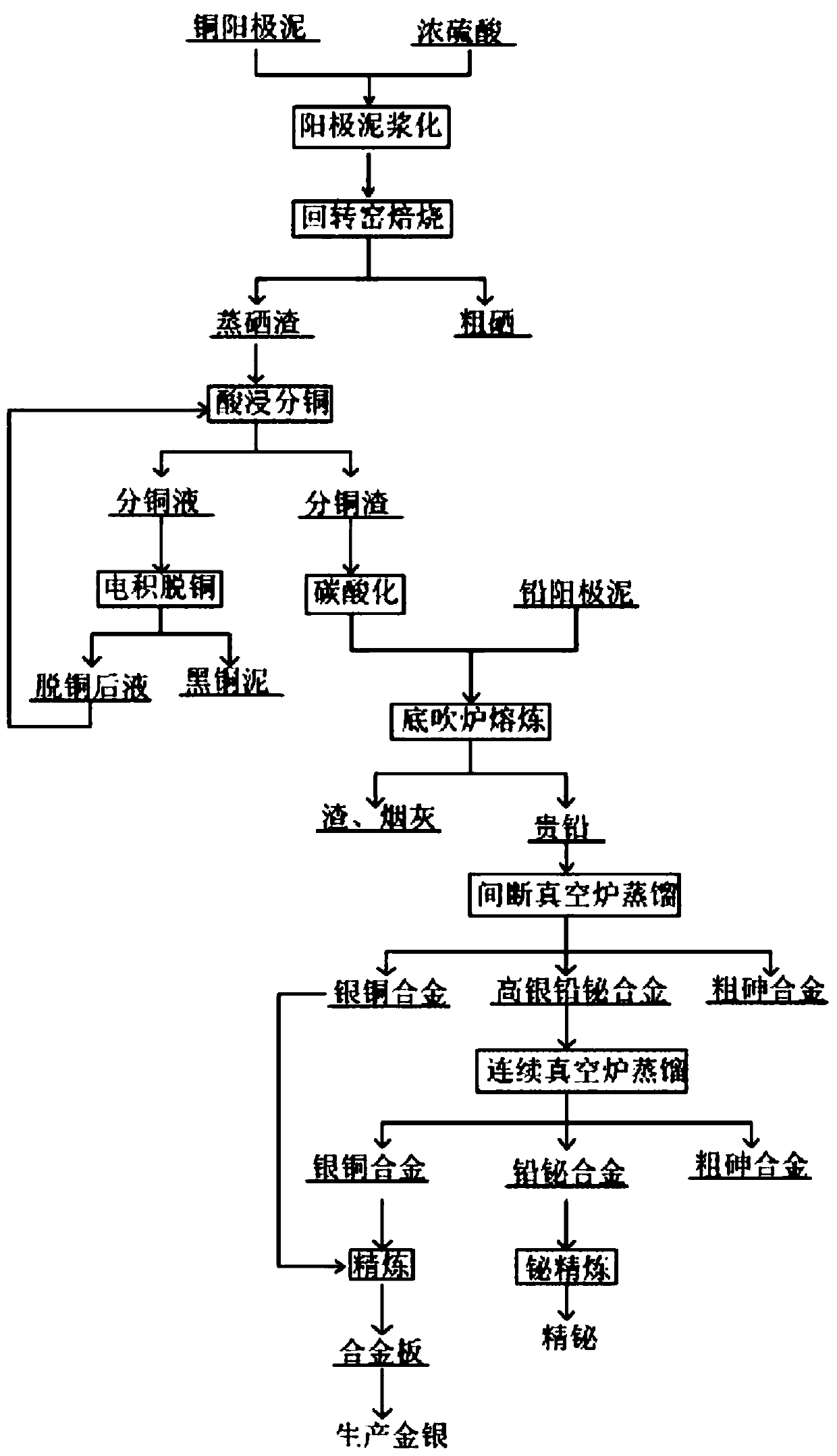

Image

Examples

Embodiment 1

[0065] In this example, lead anode slime and copper anode slime are jointly treated, wherein the content of each element in the lead anode slime and copper anode slime to be treated is specifically shown in Table 1, and the lead anode slime and copper anode slime are produced by Yuguang Gold Lead The company's lead electrolysis workshop and copper electrolysis workshop were obtained.

[0066] Table 1 Element content in lead anode slime and copper anode slime to be treated

[0067] metal element Au(g / t) Ag(%) Cu(%) Pb(%) Se(%) Te(%) As(%) Sb(%) Bi(%) copper anode slime 3527 5.09 21.86 18.65 6.35 2.42 1.49 2.54 3.81 Lead Anode Slime 954 13.4 2.59 13.67 0.02 0.60 0.59 6.07 38.89

[0068] For the joint treatment process of this lead anode slime and copper anode slime, specifically as follows:

[0069] (1) Sulfation roasting of copper anode slime

[0070] Take 1000kg of copper anode slime to be treated, add 700kg of conc...

Embodiment 2

[0090] Embodiment 2 and embodiment 1 are processed for the same lead anode slime and copper anode slime, and the process is specifically as follows:

[0091] Table 2 Element content in lead anode slime and copper anode slime to be treated

[0092] metal element Au(g / t) Ag(%) Cu(%) Pb(%) Se(%) Te(%) As(%) Sb(%) Bi(%) copper anode slime 2527 3.09 18.86 19.65 3.35 3.42 2.49 1.74 2.81 Lead Anode Slime 554 11.4 1.89 14.67 0.02 0.60 0.59 8.07 37.89

[0093] For the joint treatment process of this lead anode slime and copper anode slime, specifically as follows:

[0094] (1) Sulfation roasting of copper anode slime

[0095] Take 1000kg of copper anode slime to be treated, add 500kg of concentrated sulfuric acid to it, and slurry at room temperature for 3.5 hours; after slurring, put it in the rotary kiln for roasting; when roasting, the pressure in the rotary kiln is controlled at -8000~-9000Pa, and the control Zone temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com