Mordenite molecular sieve as well as preparation method and application thereof

A technology of mordenite and molecular sieve, which is applied in the direction of mercerized crystalline aluminum silicate zeolite, molecular sieve catalyst, molecular sieve and alkali exchange compound, etc. It can solve the problems of small particles, uncontrollable particle shape, high crystallization temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] The preparation of the former powder of embodiment 1 mordenite molecular sieve

[0109] It is synthesized by hydrothermal method, and the specific batching process is as follows, sequentially add 5.30g of water, 0.42g of sodium aluminate, 0.58g of NaOH and stir evenly, then add 13.10g of silica sol (31wt%) and mix and stir for 1 hour, then transfer the mixture to a stainless steel In the reaction kettle, seal it, and place it in an oven preheated to 165°C for crystallization for 48 hours. After the crystallization, the solid product was centrifuged, washed, and dried in air at 100° C. to obtain the original powder of mordenite molecular sieve (MOR).

Embodiment 2~17

[0110] The preparation of embodiment 2~17 mordenite molecular sieves

[0111] Mordenite molecular sieves were prepared by the following steps:

[0112] a) Mix and stir the aluminum source, the alkali source, the amine / ammonium substance and water in proportion, and record it as mixture A;

[0113] b) Soak the silicon source in A for a period of time, the volume ratio of the silicon source to A is 0.2-0.5:1; filter to remove excess liquid to obtain precursor B.

[0114] c) Pre-add the mixed liquid of nitrogen-containing compound and water in the reactor, the molar ratio of nitrogen-containing compound and water is 0.001-0.05:1, and place the precursor in step b) in the polytetrafluoroethylene in the reactor In the lining, the distance between the precursor and the liquid at the bottom of the reactor is 4-5 cm. After the reaction kettle is sealed, it is aged at 80-120°C for 0.5-12 hours. Then heat up to 150-210°C to crystallize for 24-144 hours, wash the solid product with de...

Embodiment 18

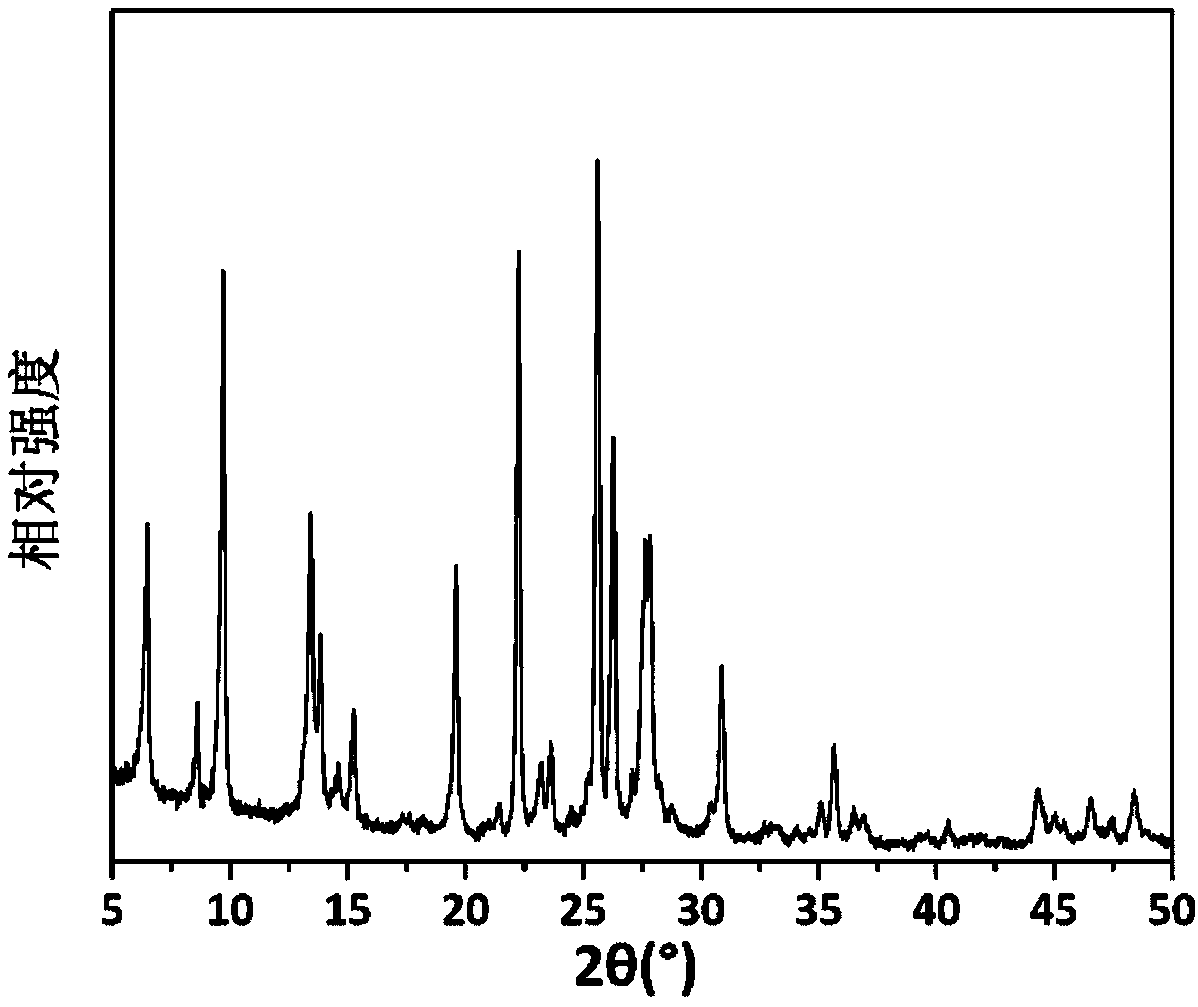

[0132] XRD characterization of embodiment 18 mordenite molecular sieve

[0133] right Example 1 The structure of the obtained sample was characterized by XRD, and the XRD data results are shown in Table 2. The results show that the sample of Example 1 conforms to the MOR structural feature through XRD analysis, that is, the obtained solid sample is mordenite molecular sieve.

[0134] The raw mordenite molecular sieve powder sample obtained in this example was used as a standard sample for XRD characterization analysis of samples obtained in subsequent examples.

[0135] right Example 2-17 The sample obtained in carries out XRD characterization, and its XRD result is compared with the XRD data of embodiment 1 sample, the result shows, the XRD data of the sample obtained in embodiment 2-17 is similar to the XRD data of embodiment 1 sample, That is, the peak positions are similar, but the peak intensities are slightly different, indicating that the samples synthesized in Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average specific surface area | aaaaa | aaaaa |

| Average pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com