Sludge resource treatment process and system

A treatment process and treatment system technology, applied in the field of sludge resource treatment process and its system, can solve the problems of inability to achieve harmlessness, incomplete resource utilization, secondary pollution, etc., and reduce the amount of exhaust gas and exhaust gas. The effect of pollutant concentration, reducing the difficulty of exhaust gas treatment and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

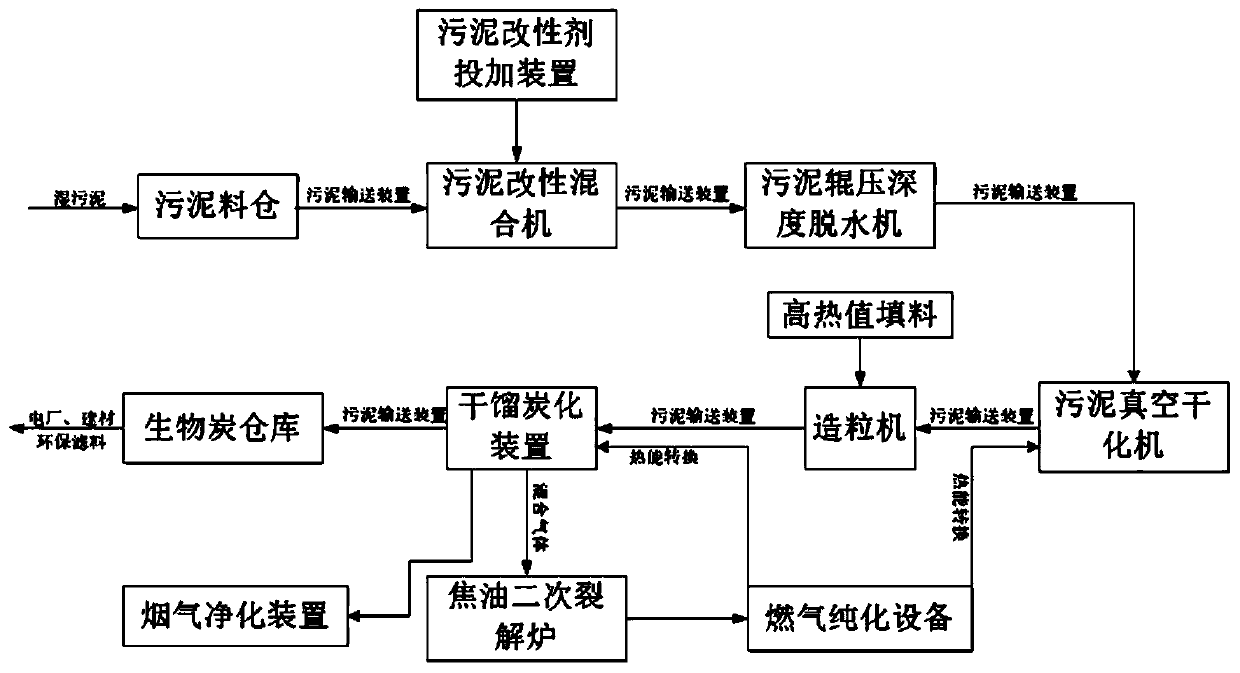

[0039] A sludge recycling process and system proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims.

[0040] see figure 1 , in one embodiment, in this embodiment, the sludge treatment process is described in detail in conjunction with the sludge resource treatment system, and the treatment process using the sludge resource treatment system is as follows:

[0041] The wet sludge with a water content of 80% to 85% is transported from the sludge silo to the sludge modification mixer through the sludge conveying device, and the sludge modifier dosing device adds the sludge modifier to the sludge modification In the permanent mixer, the sludge modifier is preferably an organic inert material, and the addition amount is 2% to 8% of the total weight of the wet sludge. The wet sludge a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com