Process and system for industrially producing biosilicon

A bio-silicon and process technology, applied in biomass post-processing, photobioreactor, biomass pre-treatment, etc., can solve the problems of difficulty in harvesting, slow growth rate, and small algal cell size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

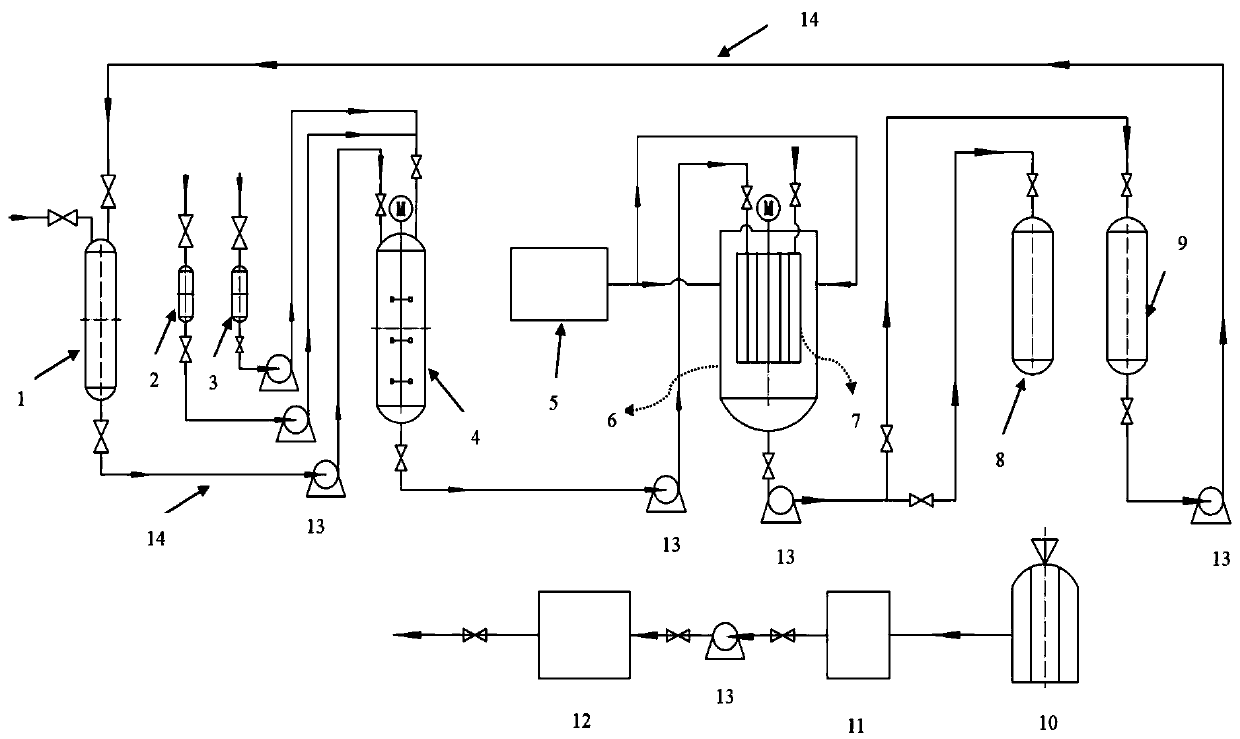

[0068] A system for industrialized production of bio-silicon, which includes a cultivation system, a harvesting-extraction system, and a pulverization system in sequence according to the technological process, and the cultivation system and the harvesting-extraction system are connected through pipelines.

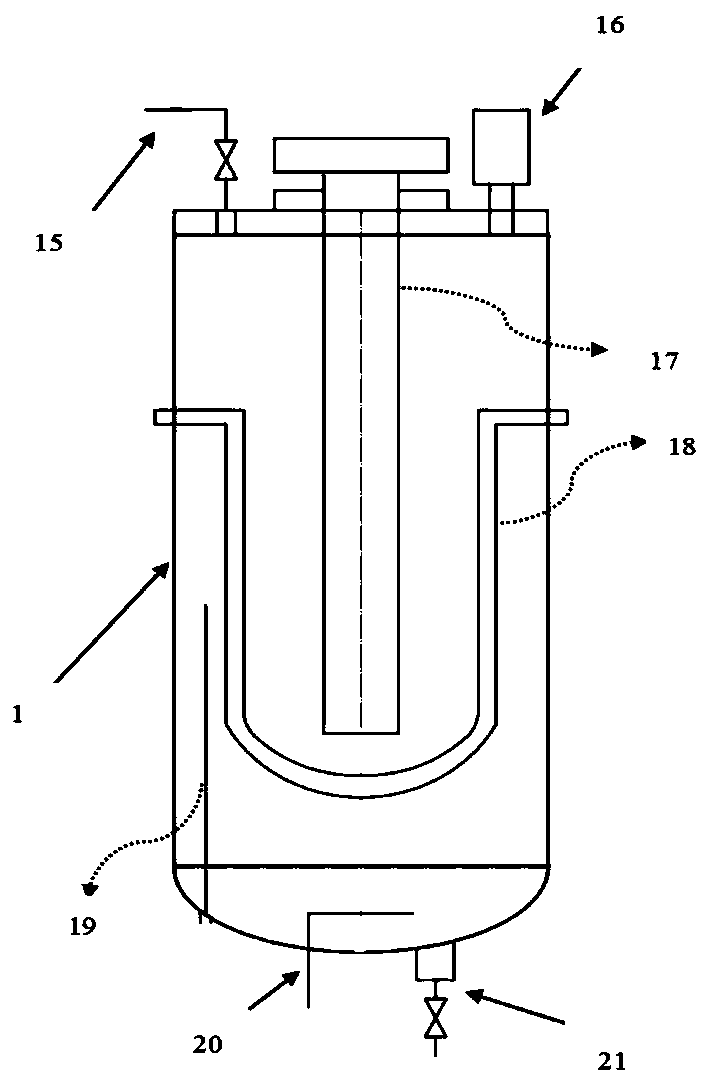

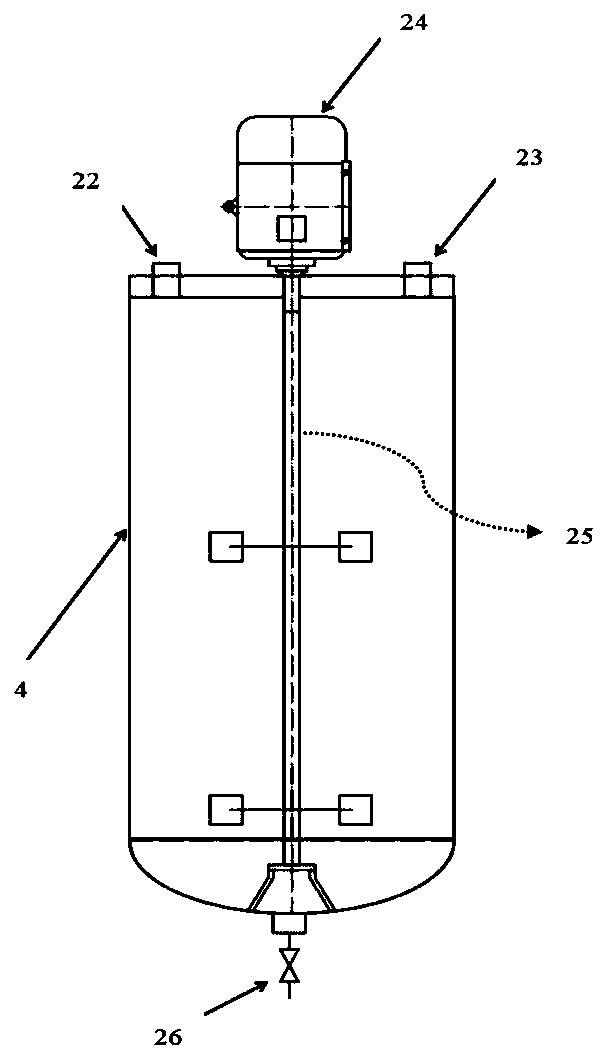

[0069] Among them, such as figure 1 As shown, the cultivation system includes a photobioreactor 1; the harvest-extraction system includes a flocculation tank 4, an algae-liquid separation tank, a medium circulation tank 9 and an organic matter storage tank 8. The flocculation tank 4 is connected with two flocculant storage tanks, namely the flocculant storage tank A 2 and the flocculant storage tank B 3; flocculation tank 4 is connected with photobioreactor 1; flocculation tank 4 is connected with inner tank 7; dehydration extraction tank 6 is connected with steam generator 5; the lower end of dehydration extraction tank is connected with organic matter storage tank 8 and c...

Embodiment 2

[0077] A system for industrialized production of bio-silicon, which includes a cultivation system, a harvesting-extraction system, and a pulverization system in sequence according to the technological process, and the cultivation system and the harvesting-extraction system are connected through pipelines.

[0078] Among them, such as figure 1 As shown, the cultivation system includes a photobioreactor 1; the harvest-extraction system includes a flocculation tank 4, an algae-liquid separation tank, a medium circulation tank 9 and an organic matter storage tank 8. The flocculation tank 4 is connected with two flocculant storage tanks, namely the flocculant storage tank A 2 and the flocculant storage tank B 3; flocculation tank 4 is connected with photobioreactor 1; flocculation tank 4 is connected with inner tank 7; dehydration extraction tank 6 is connected with steam generator 5; the lower end of dehydration extraction tank is connected with organic matter storage tank 8 and c...

Embodiment 3

[0085] A system for industrialized production of bio-silicon, which includes a cultivation system, a harvesting-extraction system, and a pulverization system in sequence according to the technological process, and the cultivation system and the harvesting-extraction system are connected through pipelines.

[0086] Among them, such as figure 1 As shown, the cultivation system includes a photobioreactor 1; the harvest-extraction system includes a flocculation tank 4, an algae-liquid separation tank, a medium circulation tank 9 and an organic matter storage tank 8. The flocculation tank 4 is connected with two flocculant storage tanks, namely the flocculant storage tank A 2 and the flocculant storage tank B 3; flocculation tank 4 is connected with photobioreactor 1; flocculation tank 4 is connected with inner tank 7; dehydration extraction tank 6 is connected with steam generator 5; the lower end of dehydration extraction tank is connected with organic matter storage tank 8 and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com