Carboxymethyl chitosan/sodium alginate nano hydrogel as well as preparation method and application

A carboxymethyl chitosan and nano-hydrogel technology, which is applied in pharmaceutical formulations, peptide/protein components, medical preparations with non-active ingredients, etc. Gel research and other issues, to achieve the effect of good protein entrapment capacity, good biosafety and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Prepare a solution of carboxymethyl chitosan (OCMC) and sodium alginate (SA) with a concentration of 2.5mg / mL. The two are ultrasonicated under the conditions of ultrasonication for 2.5s, pause for 2.5s, cycle for 60min, and power of 630w, and then press The volume ratio is 1:1, and the mixture is sonicated under the conditions of ultrasonication for 2.5s, pause for 2.5s, circulation for 30min, and power 630w.

[0051] The mixture was dropped into ethyl acetate to make water phase: organic phase = 1:9 (v:v), and mechanically stirred for 2 hours at 600 rpm. Afterwards, the product was transferred to a round-bottomed flask, and vacuum-rotated at 35° C. to remove the organic solvent to obtain an aqueous phase. Add calcium chloride solution with a concentration of 1 mg / mL according to the molar ratio of calcium ions and sodium alginate at a ratio of 1:1, stir magnetically, and cross-link at room temperature for 2 h. The product was dialyzed in deionized water for 2 days, a...

Embodiment 2

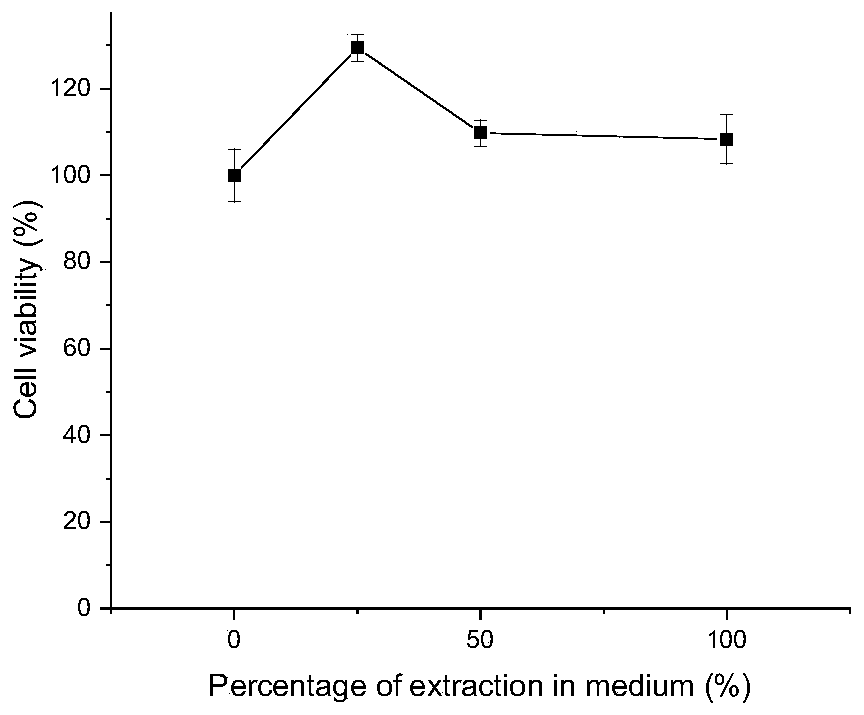

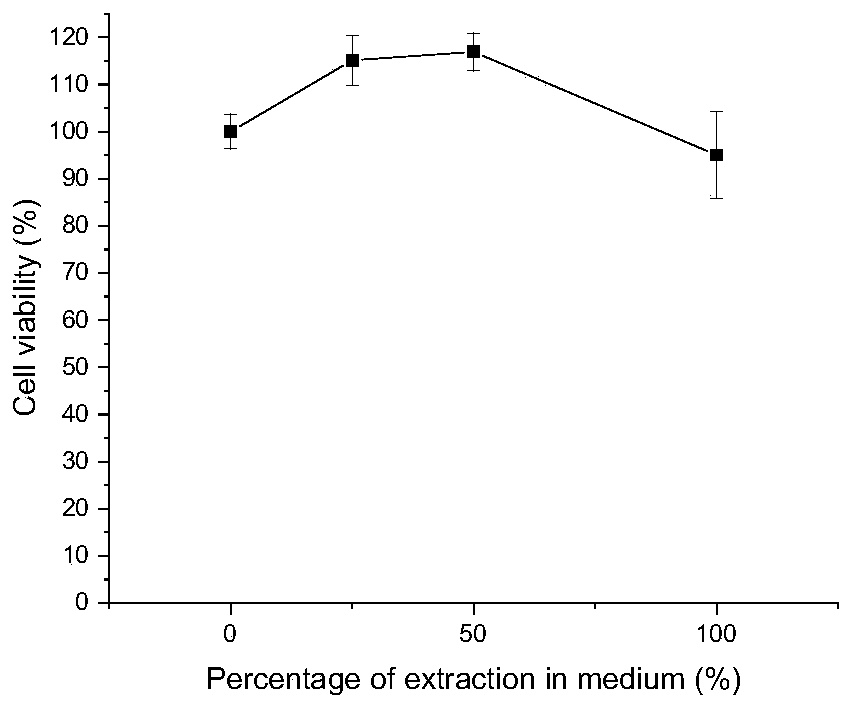

[0058] After the L929 cells were revived, cultured and passaged, the original medium was discarded, and 2-3mL PBS was added to wash twice. Add 1 mL of trypsin in PBS solution (concentration: 2.5 mg / mL, use after filter sterilization) for digestion for 3 min (put in an incubator at 37°C). After the digestion is completed, observe under the microscope, and the digestion is complete when the cells become spherical. Add 3mL medium by pipetting. Transfer to a centrifuge tube for centrifugation (1000 rpm, 5 min). Discard the supernatant, add 6 mL medium and blow up. After pipetting evenly, transfer to culture flasks, and add 3mL cell suspension to each culture flask.

[0059] After two passages, the supernatant was discarded after the cells were centrifuged, and 5 mL of medium was added again, and mixed by pipetting. Take a drop into the counting plate, dilute according to the result, and adjust the concentration to 1.5-1.8×10 4 individual / mL. After using the counting board, w...

Embodiment 3

[0064] Prepare OCMC and SA solution with a concentration of 2.5 mg / mL; prepare a BSA solution with a concentration of 5 mg / mL, take 4 mL of OCMC solution (containing 10 mg of OCMC), and add 4 (8, 12, 16) mL of BSA solution (ie OCMC:SA:BSA=1:1:2(4,6,8)(m:m:m)), ultrasonic for 2.5s, pause for 2.5s, power 630w, disperse for 10min. Then drop 4mL of SA solution (containing 10mg of SA) into it, sonicate for 2.5s, pause for 2.5s, power 630w, and disperse for 20min.

[0065] Drop the mixture into ethyl acetate, the volume ratio of aqueous phase: organic phase is 1:9, and react for 2 hours under mechanical stirring at 600rpm; the reaction system is vacuum-dried to remove the organic solvent, and the remaining aqueous phase is divided into 50mL centrifuge tubes , Centrifuge at 36400g for 30min at room temperature. Take the supernatant to measure its volume, and measure the absorbance at 280nm, and determine the BSA concentration by comparing with the BSA standard curve.

[0066] Calcu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com