Black green flame-retardant shoe edge rubber for forest fire protection shoes and preparation method thereof

A dark green, fire-fighting technology, used in applications, shoe soles, footwear, etc., can solve the problems of resistance to flame retardant ability, rubber shoes are not durable, and the application breadth is low, achieve excellent flame retardant performance, overcome easy combustion , to ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

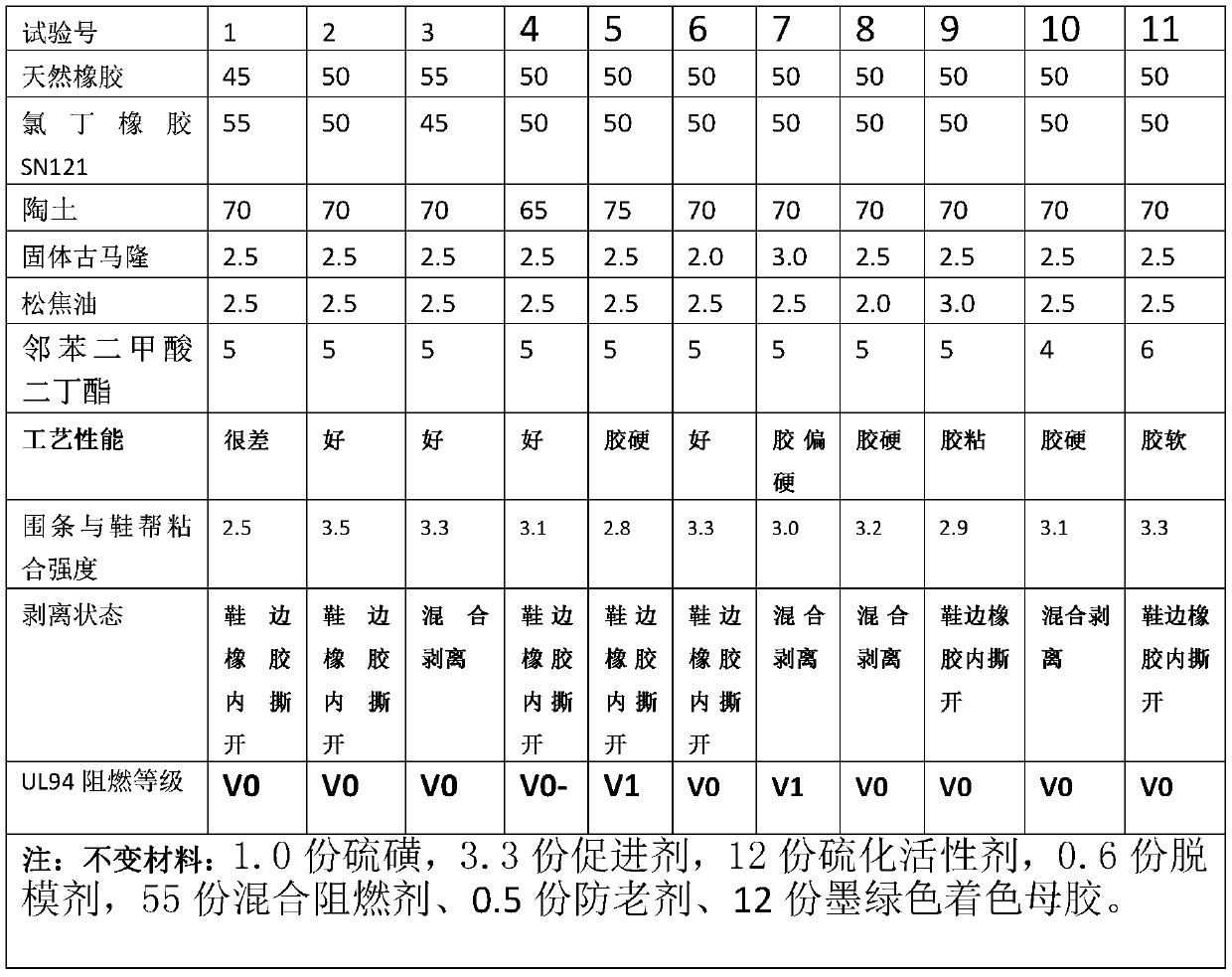

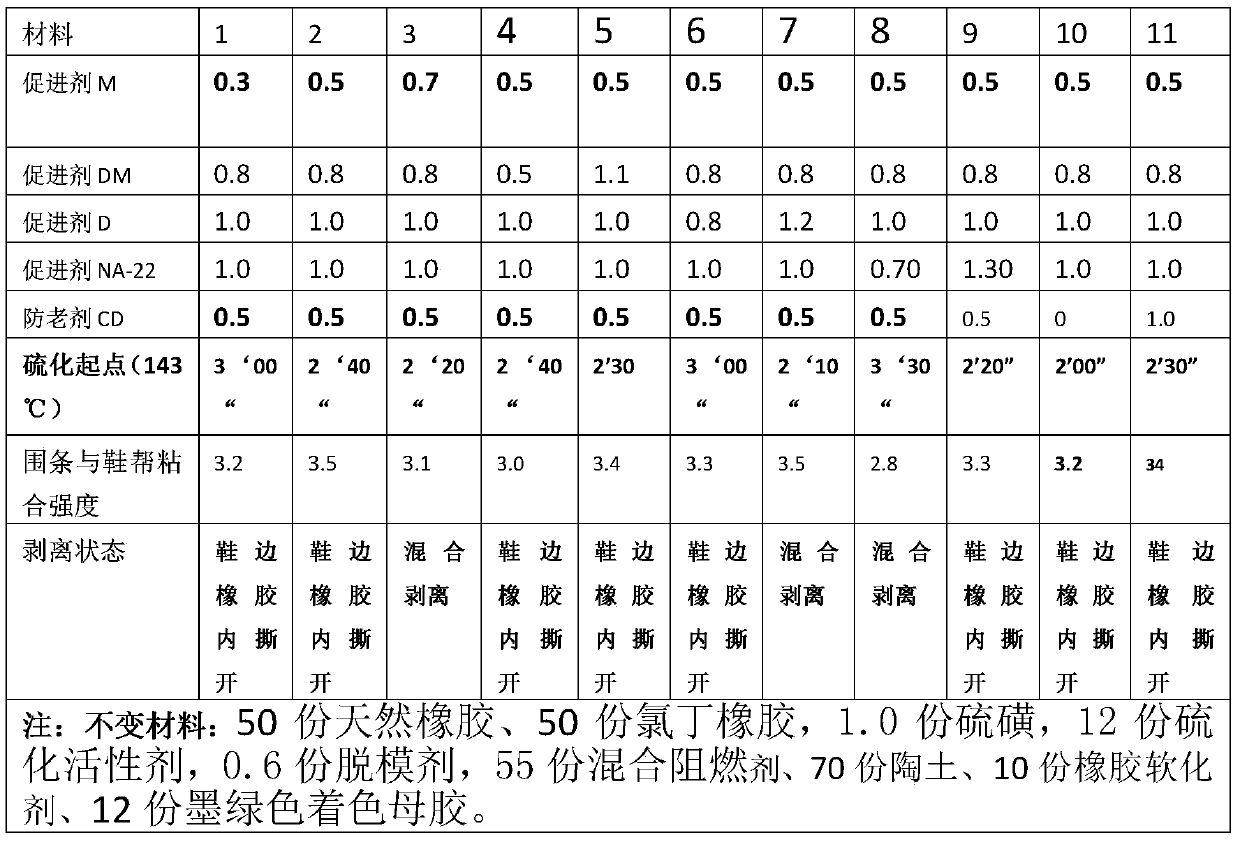

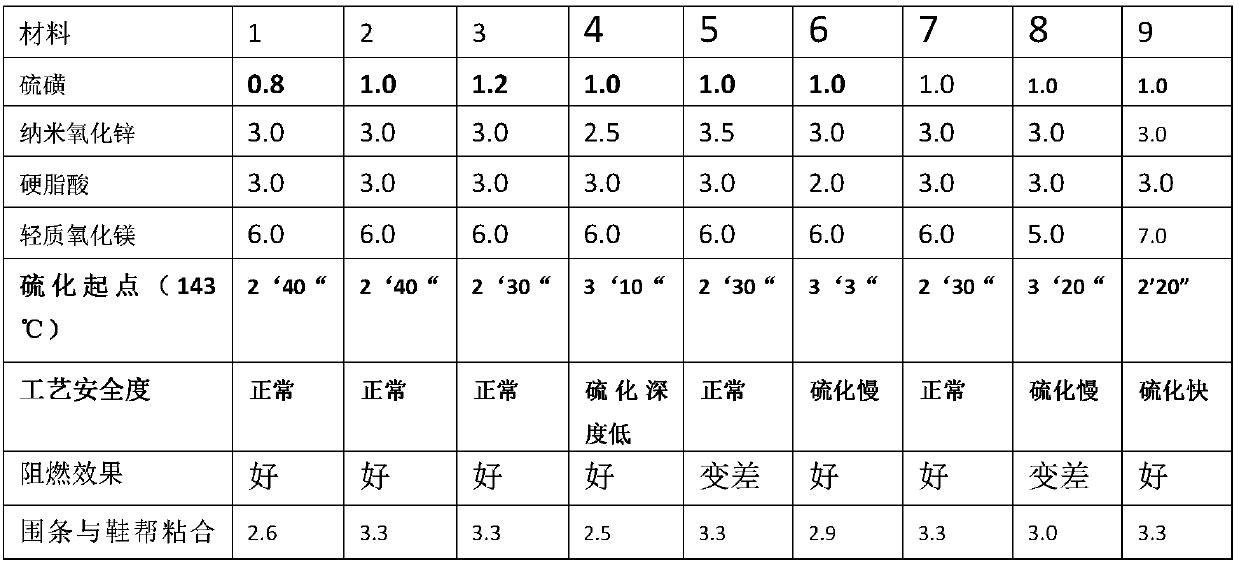

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1 of the present invention: forest fire-fighting shoes use dark green flame-retardant shoe edge rubber, calculated in parts by weight, it includes 50 parts of natural rubber, 50 parts of chloroprene rubber, 1.0 parts of sulfur, 3.3 parts of accelerator (every 3.3 parts Accelerator consists of 0.5 parts of accelerator M, 0.8 parts of accelerator DM, 1.0 part of accelerator D and 1.0 part of accelerator NA-22), 12 parts of vulcanization activator (every 12 parts of vulcanization activator consists of 3 parts of three-level hard Fatty acid and 3 parts of nano zinc oxide, 6 parts of light magnesium oxide), 0.6 parts of release agent, 70 parts of pottery clay, 10 parts of softener (every 10 parts of softener consists of 5 parts of dibutyl phthalate, 2.5 3.5 parts of solid coumarone and 3.5 parts of pine tar), 55 parts of mixed flame retardant (every 55 parts of mixed flame retardant consists of 10 parts of decabromodiphenyl ether, 25 parts of chlorinated paraffin (...

Embodiment 2

[0063] Embodiment 2 of the present invention: dark green flame-retardant shoe edge rubber for forest fire-fighting shoes, calculated in parts by weight, it includes 52 parts of natural rubber, 48 parts of neoprene, 1.0 part of sulfur, 3.3 parts of accelerator, 13 parts of vulcanization Active agent, 0.6 parts of mold release agent, 55 parts of mixed flame retardant, 70 parts of pottery clay, 10 parts of rubber softener, 0.5 part of anti-aging agent, 12.5 parts of dark green colored masterbatch.

[0064] The preparation method of dark green flame-retardant shoe edge rubber for forest fire-fighting shoes,

[0065] 1) To make 12.5 dark green masterbatch: first put 6.0 parts of natural rubber (plasticity 0.35-0.40) into the XK-160 open rubber mixing machine to wrap the roll, and add 0.5 parts of N330 carbon black, 0.2 parts of N330 carbon black and 0.2 parts of Add B8905 blue masterbatch, 0.1 part of G5319 phthalocyanine green, and 0.5 part of paraffin to the natural rubber produc...

Embodiment 3

[0068] Embodiment 3 of the present invention: forest fire-fighting shoes use dark green flame-retardant shoe edge rubber, calculated in parts by weight, it includes 48 parts of natural rubber, 52 parts of chloroprene rubber, 1.0 part of sulfur, 3.3 parts of accelerator (every 3.3 parts Accelerator consists of 0.5 parts of accelerator M, 0.8 parts of accelerator DM, 1.0 part of accelerator D and 1.0 part of accelerator NA-22), 11.5 parts of vulcanization activator (every 12 parts of vulcanization activator consists of 2.5 parts of three-level hard Fatty acid and 3 parts of nano zinc oxide, 6.0 parts of light magnesium oxide), 0.6 parts of mold release agent, 70 parts of pottery clay, 10 parts of softener (every 10 parts of softener consists of 5 parts of dibutyl phthalate, 2.5 parts of 3.5 parts of solid coumarone and 3.5 parts of pine tar), 52 parts of mixed flame retardant (every 52 parts of mixed flame retardant consists of 10 parts of decabromodiphenyl ether, 22 parts of chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com