A kind of superfine package type cadmium sulfur selenide ceramic pigment and preparation method thereof

A technology of cadmium sulfoselenide and ceramic pigments, which is applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problem of poor reproducibility of packaged pigments with an average particle size of less than 1 μm and difficulties of packaged pigments , uncontrollable reaction and other problems, achieve the dispersion effect and the reaction process is controllable and easy to control, maintain the dispersion effect, and have good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for preparing an encapsulated cadmium sulfoselenide ceramic pigment, comprising the following steps:

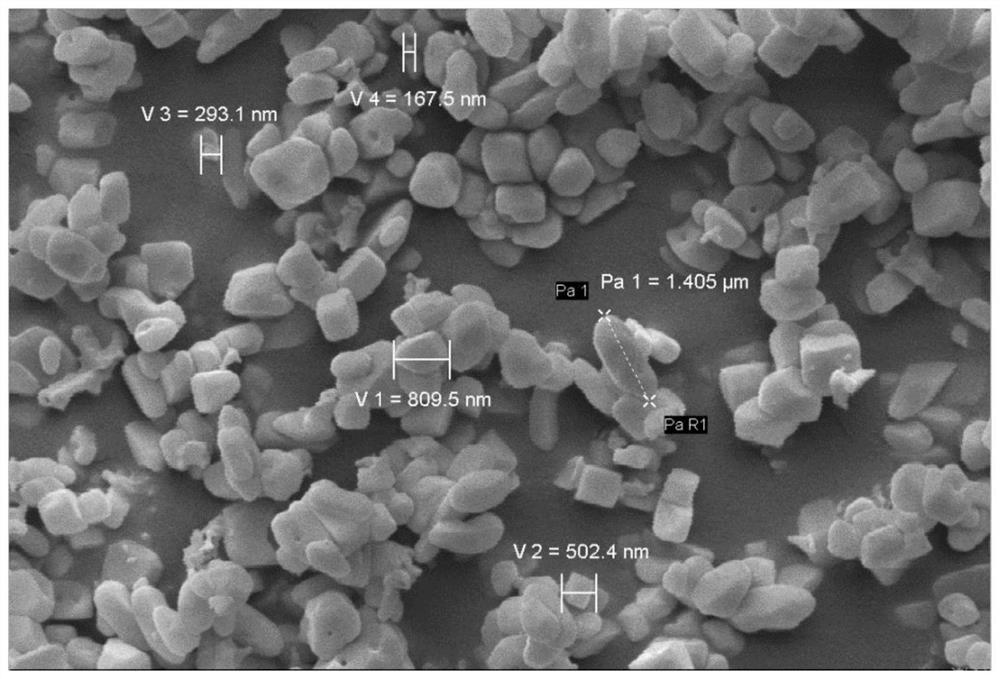

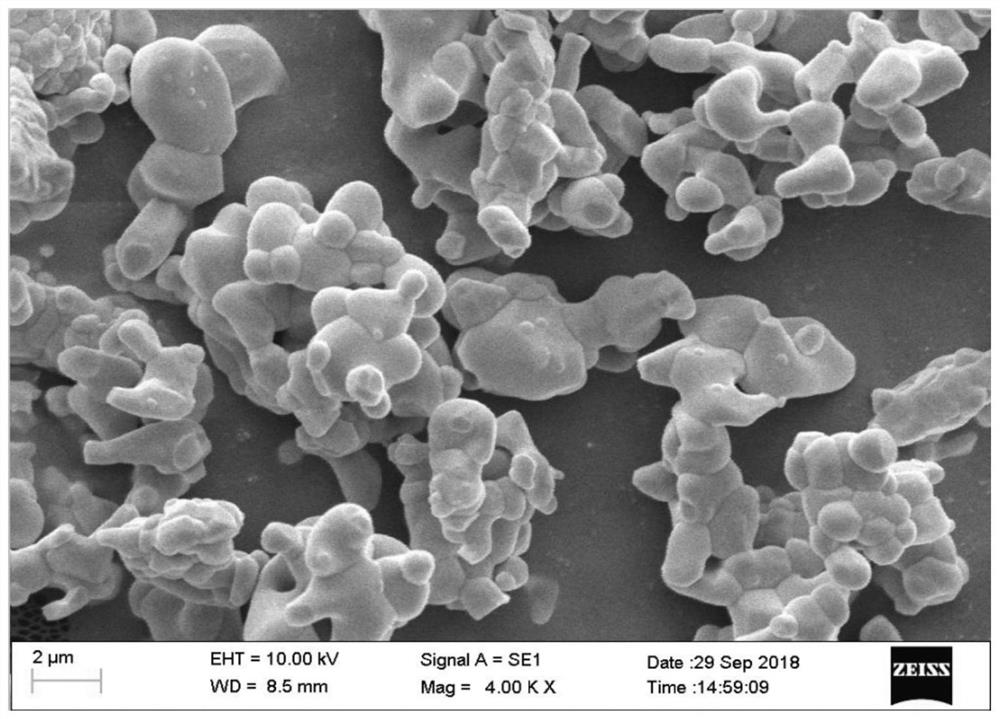

[0052] 1) Dissolve cadmium sulfate, polyvinylpyrrolidone and polyethyleneimine in water to obtain solution A, dissolve sodium sulfide and selenium in water to obtain an alkali solution, drop solution A into the alkali solution at a rate of 3mL / min to obtain sulfur Cadmium selenide precursor, move the precursor into the reaction kettle, react at a temperature of 180°C for 26 hours, wash with water to obtain monodisperse nano-scale cadmium sulfur selenide, the particle size D100 is about 26nm;

[0053] 2) Slowly add water glass into the sulfuric acid solution, and control its pH=0.8 to obtain a clear silicic acid solution;

[0054] 3) Adding cadmium sulfoselenide to the zirconium oxychloride solution containing sodium polyacrylate and hydroxypropyl cellulose is fully dispersed, wherein the mass percentage concentration of sodium polyacrylate is 0.5%, and the mas...

Embodiment 2

[0058] A method for preparing an encapsulated cadmium sulfoselenide ceramic pigment, comprising the following steps:

[0059] 1) Dissolve cadmium sulfate, polyvinylpyrrolidone and polyethyleneimine in water to obtain solution A, dissolve sodium sulfide and selenium in water to obtain an alkali solution, drop solution A into the alkali solution at a rate of 3mL / min to obtain sulfur Cadmium selenide precursor, move the precursor into the reaction kettle, react at a temperature of 180°C for 26 hours, wash with water to obtain monodisperse nano-scale cadmium selenide sulfur, the particle size D100 is about 25nm;

[0060] 2) Slowly add water glass into the sulfuric acid solution, and control its pH=0.8 to obtain a clear silicic acid solution;

[0061] 3) Adding cadmium sulfoselenide to the zirconium oxychloride solution containing sodium polyacrylate and hydroxypropyl cellulose is fully dispersed, wherein the mass percentage concentration of sodium polyacrylate is 0.5%, and the mas...

Embodiment 3

[0065] A method for preparing an encapsulated cadmium sulfoselenide ceramic pigment, comprising the following steps:

[0066] 1) Dissolve cadmium sulfate, polyvinylpyrrolidone and polyethyleneimine in water to obtain solution A, dissolve sodium sulfide and selenium in water to obtain an alkali solution, drop solution A into the alkali solution at a rate of 3mL / min to obtain sulfur Cadmium selenide precursor, move the precursor into the reaction kettle, react at a temperature of 180°C for 26 hours, wash with water to obtain monodisperse nano-scale cadmium selenide sulfur, the particle size D100 is about 27nm;

[0067] 2) Slowly add water glass into the sulfuric acid solution, and control its pH=0.8 to obtain a clear silicic acid solution;

[0068] 3) Adding cadmium sulfoselenide to the zirconium oxychloride solution containing sodium polyacrylate and hydroxypropyl cellulose is fully dispersed, wherein the mass percentage concentration of sodium polyacrylate is 0.5%, and the mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com