Rare earth element-contained grain refiner and preparation method and application thereof

A grain refiner and rare earth element technology, which is applied in the application of cemented carbide composite grain refiner in the preparation of fine-grained cemented carbide, and in the field of cemented carbide grain refiner materials to achieve excellent comprehensive performance , the effect of small particle size and good structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

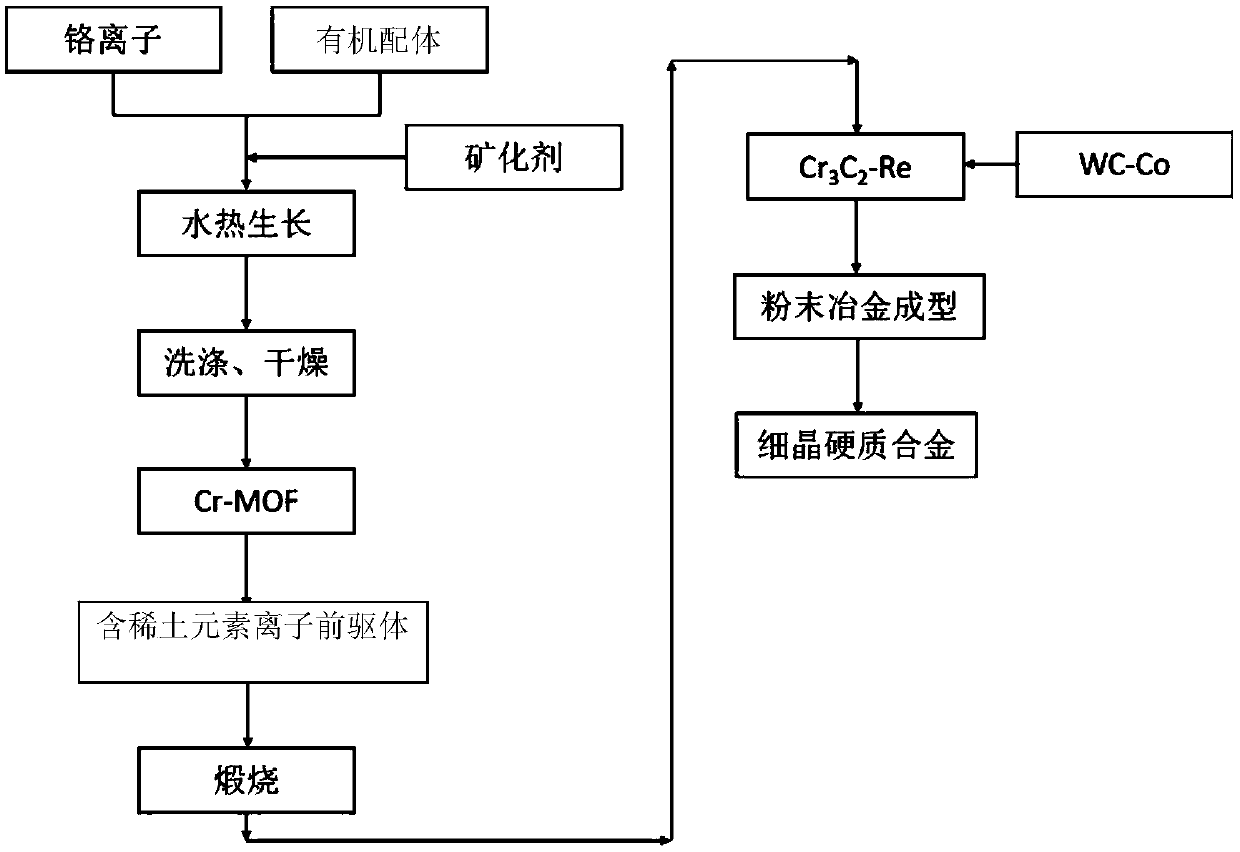

[0027] see figure 1 As shown, one aspect of the embodiments of the present invention provides a method for preparing a rare earth element-containing grain refiner, which includes:

[0028] Provide chromium-containing metal-organic framework materials (Cr-MOF materials);

[0029] The metal-organic framework material containing chromium is infiltrated and adsorbed in the ion precursor containing rare earth elements, and then calcined to form composite chromium carbide containing rare earth elements to obtain a grain refiner containing rare earth elements.

[0030] In some embodiments, the preparation method includes: performing a hydrothermal reaction at 100-300° C. for 2-24 hours in a uniformly mixed reaction system comprising chromium ions, organic ligands and water, to obtain a metal-organic framework material containing chromium.

[0031] The invention utilizes the special space structure such as rich surface area and porous characteristics of the metal-organic framework ma...

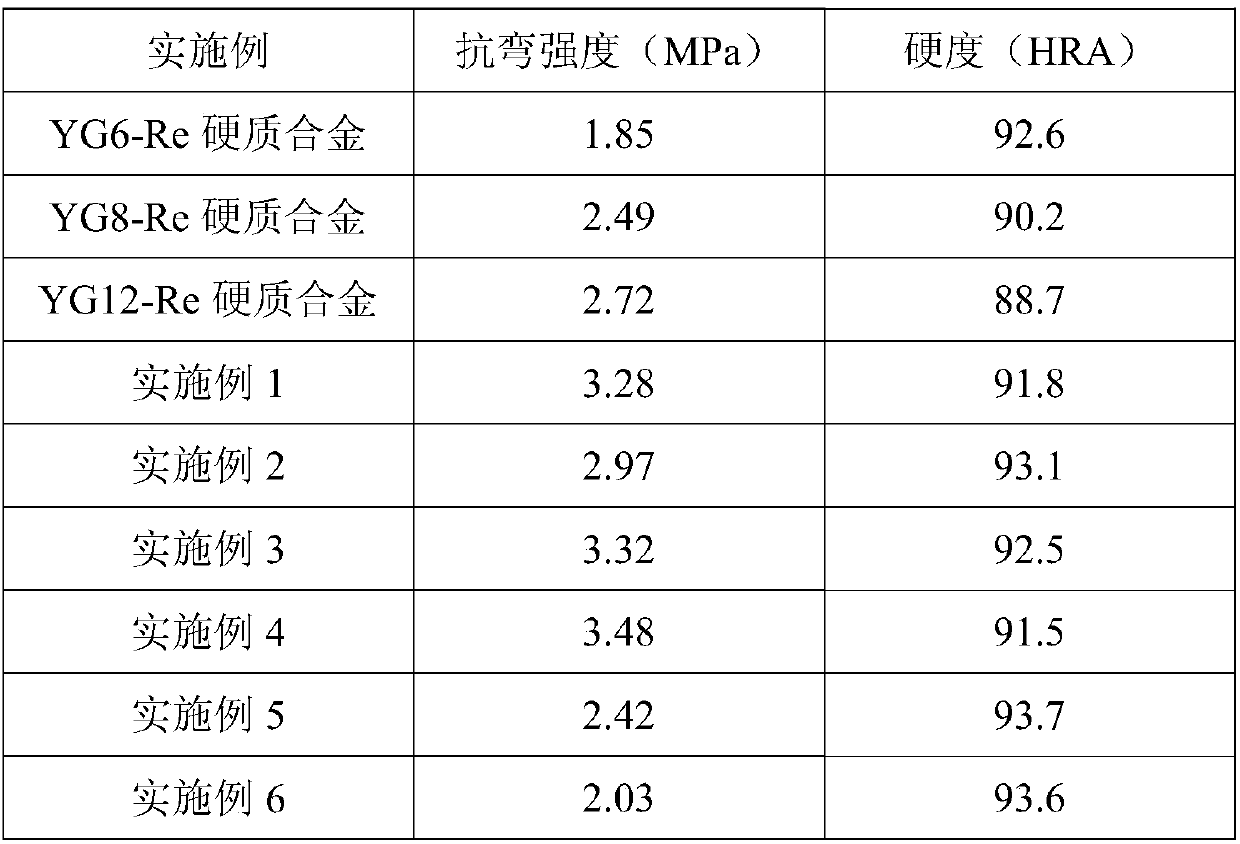

Embodiment 1

[0062] First configure 500ml of 0.1mol / L chromium nitrate aqueous solution, then add 0.05mol phthalic acid, mix well and put it into a polytetrafluoroethylene-lined reaction kettle, seal it and place it in an oven, heat it up to 150°C and keep it warm for 12h . After the heat preservation was completed, cool to room temperature, pour out the reaction product, separate by filtration, wash with pure water and ethanol during this period, and finally vacuum-dry at 60°C for 4 hours to obtain a chromium-containing MOF material (ie Cr-MOF). Then the Cr-MOF was soaked in the lanthanum nitrate solution, separated by filtration, and vacuum-dried at 60° C. for 30 min to obtain Cr-MOF containing rare earth elements (Cr-MOF-Re). Then put the Cr-MOF-Re into the quartz tube furnace, pass through the nitrogen protection, raise the temperature to 300°C at 5°C / min, keep it for 30min, then continue to raise the temperature to 800°C at 50°C / min, keep it for 1h, and then with the furnace After co...

Embodiment 2

[0064] First configure 500ml of 0.5mol / L chromium chloride aqueous solution, then add 0.25mol terephthalic acid, mix well and put it into a polytetrafluoroethylene-lined reaction kettle, seal it and place it in an oven, heat up to 100°C and keep it warm 12h. After the heat preservation was completed, cool to room temperature, pour out the reaction product, separate by filtration, wash with pure water and ethanol during this period, and finally vacuum-dry at 60°C for 4 hours to obtain a chromium-containing MOF material (ie Cr-MOF). Then the Cr-MOF was soaked in an aqueous cerium sulfate solution, separated by filtration, and vacuum-dried at 60° C. for 30 min to obtain Cr-MOF (Cr-MOF-Re) containing rare earth elements. Then put the Cr-MOF-Re into the quartz tube furnace, pass through the nitrogen protection, raise the temperature to 300°C at 5°C / min, keep it for 30min, then continue to raise the temperature to 800°C at 50°C / min, keep it for 1h, and then with the furnace After b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com