Degradable biomass organic substrate, preparation method and application method

An organic substrate and biomass technology, applied in the fields of botanical equipment and methods, planting substrates, applications, etc., can solve problems such as difficulty in meeting crop growth needs, increasing agricultural production costs, lack of pressing technology, etc., to improve the utilization rate of chemical fertilizers, The effect of improving fertilizer utilization and increasing crop yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

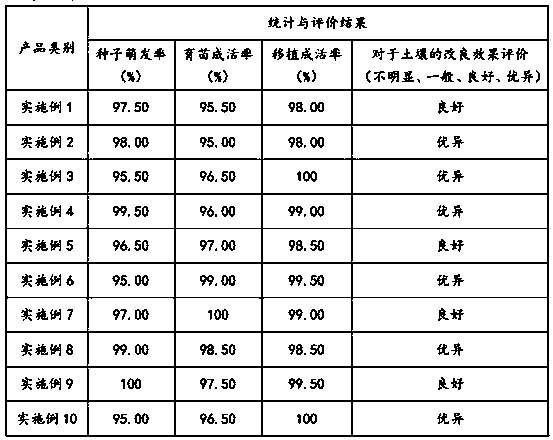

Examples

Embodiment 1

[0039] (1) Material preparation: Accurately weigh 120kg of organic fertilizer, 6kg of inorganic compound fertilizer, 0.2kg of humic acid, 0.2kg of biochar fertilizer, 0.2kg of water retaining agent, 0.02kg of rooting agent, 10kg of adhesive, 54.65kg of water, 27.324g of biological bacteria agent for use; Among them, the organic fertilizer is a mixture of 60kg decomposed straw and 60kg decomposed animal manure, the decomposed straw is the crop straw that has been decomposed, sterilized and harmless, and the decomposed animal manure is decomposed, sterilized Disinfected and harmless poultry and livestock manure; inorganic compound fertilizer is Stanley compound fertilizer; humic acid is fulvic acid, biochar fertilizer is crop straw charcoal, and water retaining agent is polyacrylamide (PAM) degradable , the rooting agent is indole acetic acid; the binder is starchy degradable organic biomass; the biological bacteria agent is the biological functional bacteria produced by Guangzho...

Embodiment 2

[0044] (1) Material preparation: Accurately weigh 140kg of organic fertilizer, 8.5kg of inorganic compound fertilizer, 0.4kg of humic acid, 0.4kg of biochar fertilizer, 0.4kg of water retaining agent, 0.04kg of rooting agent, 10kg of binder, and 71.88kg of water according to the formula requirements 1, 103.831g of biological agent for use; Among them, the organic fertilizer is a mixture of 70kg of decomposed straw and 70kg of decomposed animal manure. Bacterial disinfection and harmless treatment of poultry and livestock manure; inorganic compound fertilizer is Stanley compound fertilizer; humic acid is humic acid, biochar fertilizer is bamboo charcoal, water retaining agent is polyacrylamide (PAM) degradable, The rooting agent is sodium naphthalene acetate; the binder is starchy degradable organic biomass; the biological bacteria agent is biological functional bacteria produced by Guangzhou Weiyuan Biotechnology Co., Ltd., powder, and the number of effective viable bacteria is...

Embodiment 3

[0049] (1) Material preparation: Accurately weigh 160kg of organic fertilizer, 11kg of inorganic compound fertilizer, 0.6kg of humic acid, 0.6kg of biochar fertilizer, 0.6kg of water retaining agent, 0.06kg of rooting agent, 10kg of adhesive, 91.43kg of water, 201.146g of biological bacteria agent is reserved; among them, the organic fertilizer is a mixture of 80kg decomposed straw and 80kg decomposed animal manure, the decomposed straw is the crop straw that has been decomposed, sterilized and harmless, and the decomposed animal manure is decomposed, sterilized Disinfected and harmless poultry and livestock manure; inorganic compound fertilizer is Stanley compound fertilizer; viscous humic acid is a mixture of 0.3kg fulvic acid and 0.3kg humic acid; biochar fertilizer is 0.3kg crop straw charcoal and A mixture of 0.3kg of bamboo charcoal, the water-retaining agent is a degradable polyacrylamide (PAM), the rooting agent is a mixture of 0.03kg of indole acetic acid and 0.03kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com