Method for preparing hexagonal flaky magnesium hydroxide for flame retardants by using large-grain-size magnesium hydroxide hydrothermal method

A technology of magnesium hydroxide and hexagonal flakes, applied in the direction of magnesium hydroxide, etc., to achieve good economic benefits, large application value and market value, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

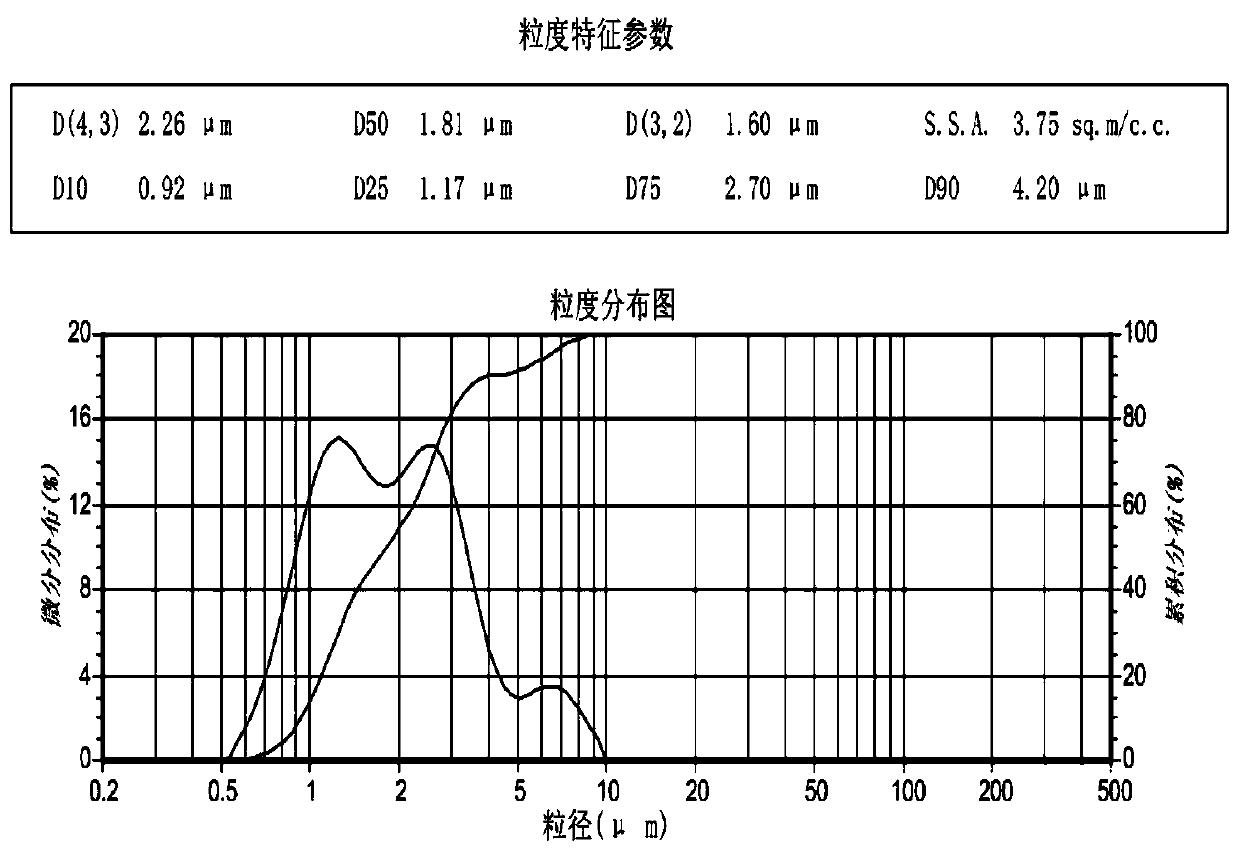

[0020] Example 1. 1. Preparation of reaction raw materials: Weigh 80g of large particle size magnesium hydroxide (with a particle size of 40-60μm), weigh 81.32g of bischofite, measure 1520mL of distilled water, and add to 2L In the high temperature and high pressure reactor device.

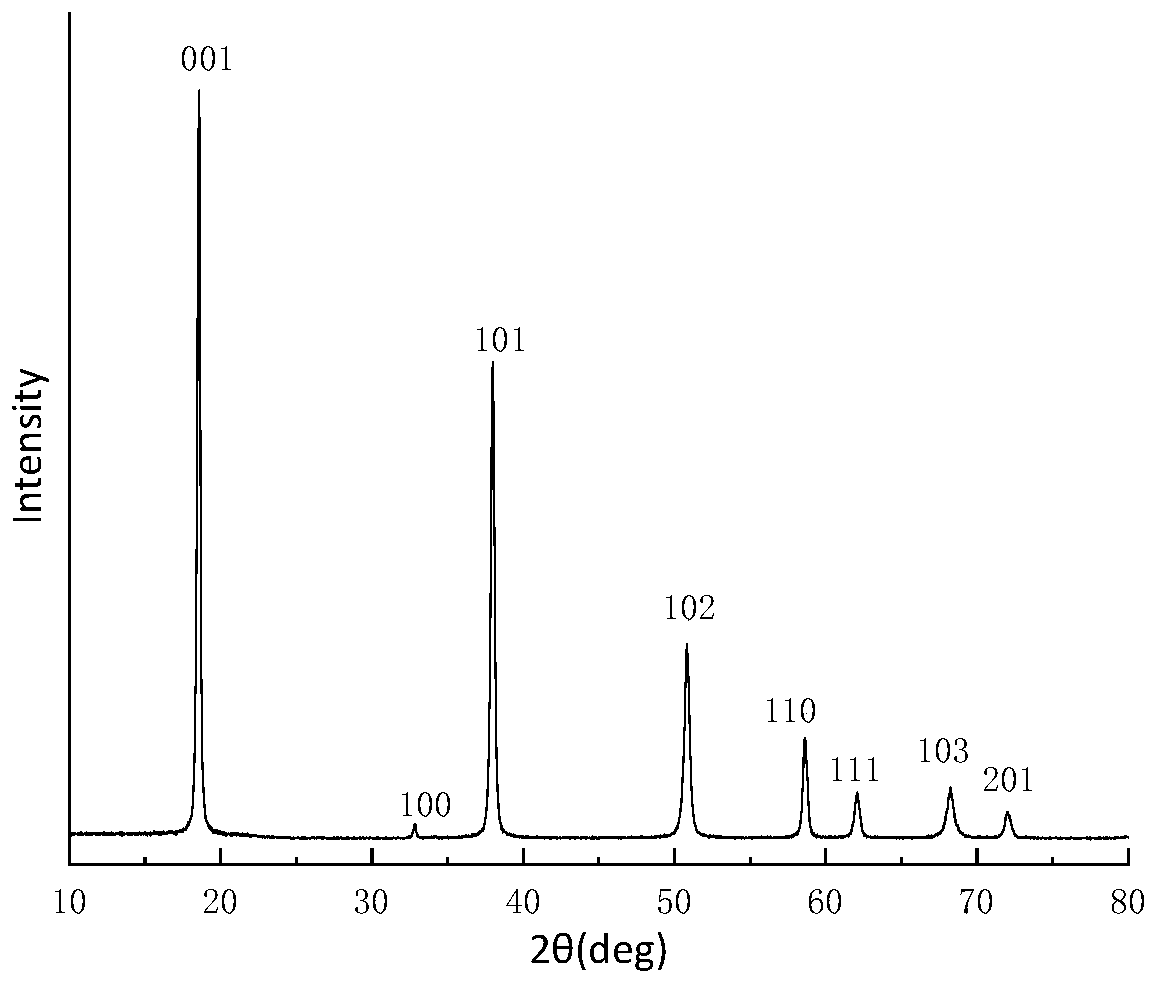

[0021] 2. Preparation of Magnesium Hydroxide for Flame Retardant Grade: Seal the high temperature and high pressure reactor device with raw materials, adjust the temperature to 160℃, and adjust the speed to 500r / min. When ready, start the high temperature and high pressure reactor device at 160℃ , And react for 6h at 500r / min. The product is filtered, washed 5 times, and dried to obtain a flame-retardant grade hexagonal flake magnesium hydroxide. The calculated magnesium hydroxide I 001 / I 101 And I 001 / I 110 The polarity ratios are 1.57 and 3.81 respectively. X-ray diffraction experiments have confirmed that it is magnesium hydroxide with extremely low polarity. Scanning electron microscopy shows ...

Embodiment 2

[0022] Example 2: Preparation of reaction raw materials: weigh 75g of large particle size magnesium hydroxide (particle size 40-60μm), weigh 77g of bischofite, measure 1440mL of distilled water, and add it to 2L of high temperature and high pressure reaction In the kettle device. The other processes are the same as in Example 1.

Embodiment 3

[0023] Example 3 Preparation of reaction raw materials: Weigh 85g of large particle size magnesium hydroxide (particle size 40-60μm), weigh 86g of bischofite, measure 1600mL of distilled water, and add it to 2L of high temperature and high pressure reaction In the kettle device, other processes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com