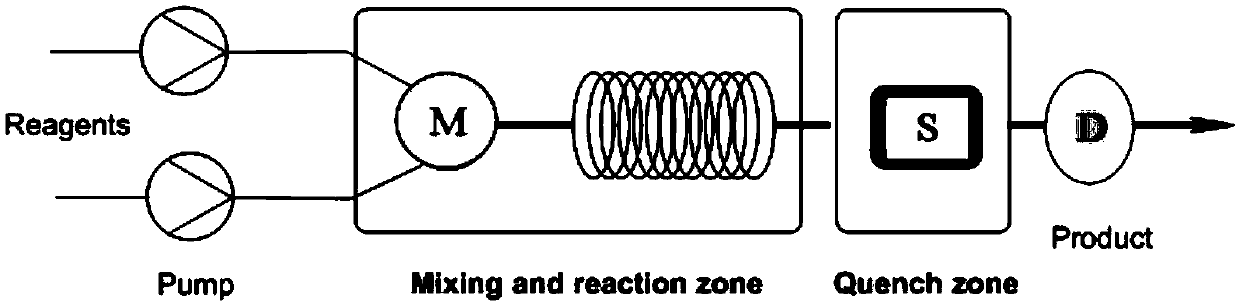

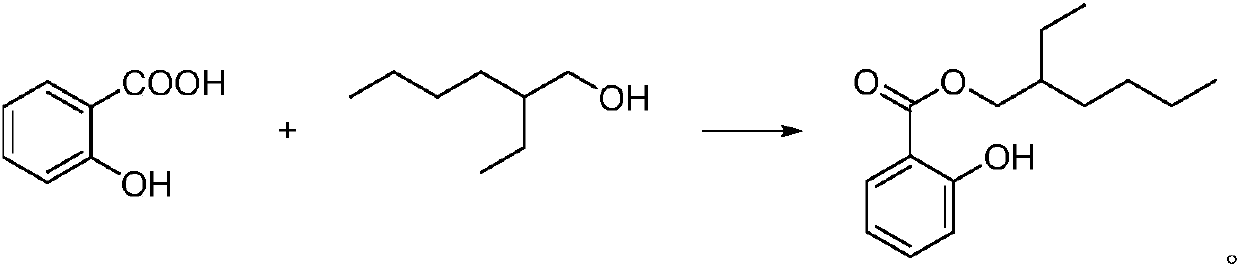

Method for continuously synthesizing isooctyl salicylate in micro-channels

A technology of isooctyl salicylate and microchannels is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc. The effect of reaction efficiency, fast mass transfer, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 138g (1mol) salicylic acid and dissolve it in an appropriate amount of xylene; get 390g (3mol) isooctanol (2-ethylhexanol) and dissolve it in an equal amount of xylene, and add 10g p-toluenesulfonic acid as a catalyst, After fully dissolving, the two solutions were simultaneously pumped into the microchannel with a high-pressure constant-flow pump, maintaining a constant flow rate, and continuously reacting at a temperature of 150 °C. , saturated sodium carbonate solution, washed with distilled water at 65°C, then dried with anhydrous sodium sulfate, and suction filtered to obtain a mixed solution. Then use a vacuum pump to distill under reduced pressure, steam out isooctyl alcohol and the solvent for recycling, and finally collect the fraction at 123 ° C to obtain isooctyl salicylate, a colorless or light yellow transparent oily liquid, the yield can reach 96%, and the gas phase purity is 99%.

Embodiment 2

[0025] Take 138g (1mol) salicylic acid and dissolve it in an appropriate amount of xylene; take 390g (3mol) isooctanol (2-ethylhexanol) and dissolve it in an equal amount of xylene, and add 15g p-toluenesulfonic acid as a catalyst, After fully dissolving, the two solutions were simultaneously pumped into the microchannel with a high-pressure constant-flow pump, maintaining a constant flow rate, and continuously reacting at a temperature of 150 °C. , saturated sodium carbonate solution, washed with distilled water at 65°C, then dried with anhydrous sodium sulfate, and suction filtered to obtain a mixed solution. Then use a vacuum pump to depressurize distillation, steam out isooctanol and the solvent for recycling, and finally collect the fraction at 123 ° C to obtain isooctyl salicylate, a colorless or light yellow transparent oily liquid, the yield can reach 94%, and the gas phase purity is 99%.

Embodiment 3

[0027] Weigh 138g (1mol) salicylic acid and dissolve it in an appropriate amount of xylene, take 390g (3mol) isooctanol (2-ethylhexanol) and dissolve it in an equal amount of xylene, and add 10g p-toluenesulfonic acid as a catalyst, After fully dissolving, the two solutions were simultaneously pumped into the microchannel with a high-pressure constant-flow pump, maintaining a constant flow rate, and reacting continuously at a temperature of 160 °C. , saturated sodium carbonate solution, washed with distilled water at 65°C, then dried with anhydrous sodium sulfate, and suction filtered to obtain a mixed solution. Then use a vacuum pump to distill under reduced pressure, steam out isooctyl alcohol and the solvent for recycling, and finally collect the fraction at 123 ° C to obtain isooctyl salicylate, a colorless or light yellow transparent oily liquid, the yield can reach 91%, and the gas phase purity is 99 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com