Novel die bonding film

A die-bonding and thin-film technology, which is applied in the fields of interconnection and third-generation semiconductor packaging die-bonding, can solve the problems of high surface energy, easy oxidation and vulcanization, etc., and achieve the effect of high Young's modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

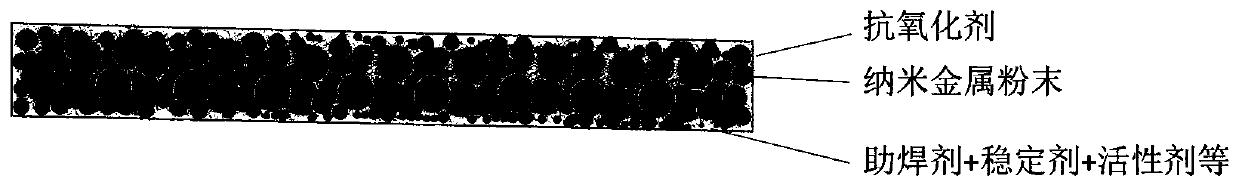

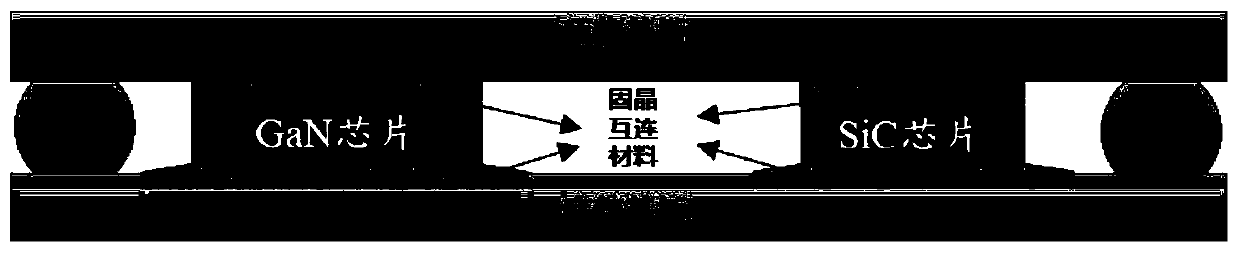

[0024] This embodiment proposes a new type of crystal-bonding film, such as figure 1 As shown, it is a schematic diagram of a new type of crystal-bonding film, which is characterized in that it includes nano-metal powder, antioxidant, flux, stabilizer, and active agent, wherein the nano-metal powder is metal Au as the shell layer, and Cu is the core-shell structure of the core layer , the metal powder content is 65wt.%, the antioxidant polyethylene glycol and oleic acid mixture content is 30wt.%, the flux-activating rosin content is 1wt.%, the stabilizer is polyvinylpyrrolidone (PVP), and the active agent is mainly composed of Zinc chloride, wherein the total amount of flux, stabilizer and active agent is ≤10.0wt.%. The role of the active agent is to remove oxides on the surface of the nano-metal, reduce the surface tension of the molten nano-metal material, improve its wettability, and prevent secondary oxidation during the sintering process. Such as figure 2 Shown is a sc...

Embodiment 2

[0028] This embodiment proposes a new type of crystal-bonding film, such as figure 1 As shown, it is a schematic diagram of a new type of crystal-bonding film, which is characterized in that it includes nano-metal powder, antioxidant, flux, stabilizer, and active agent, wherein the nano-metal powder is Cu powder, and the content of Cu powder is 50wt.%. Antioxidant three Ethanolamine, the content is 40wt.%, the flux stearic acid content is 3wt.%, the stabilizer is cetyl ammonium bromide (CTAB), and the main component of the active agent is citric acid, wherein the flux, stabilizer and active agent Total amount≤10.0wt.%. The role of the active agent is to remove oxides on the surface of the nano-metal, reduce the surface tension of the molten nano-metal material, improve its wettability, and prevent secondary oxidation during the sintering process. Nano-Cu powder, antioxidant, soldering flux, stabilizer, and activator are mixed and pressed to form a dark film with a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com