Self-polishing antiseptic antiscale coating and preparing method thereof

An anti-scaling coating and self-polishing technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems that are difficult to achieve self-polishing anti-corrosion, anti-scaling, electrochemical corrosion, roughness increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing a self-polishing anti-corrosion and anti-fouling coating, comprising the following steps:

[0045] Step 1, the surface of the oil pipe, casing or ground pipeline is degreased, sand blasted and derusted, cleaned and dried;

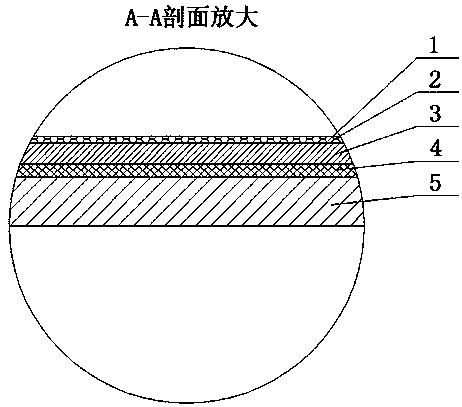

[0046] Step 2, using a thermal spraying method to spray the inert metal on the inner or outer wall of the pipeline as an inert metal layer;

[0047] Step 3, using a thermal spraying method to spray the active metal on the outside of the inert metal layer as an intermediate layer;

[0048] Step 4, use the brushing method to brush the material of polymer or passivated liquid alloy on the outside of the middle layer as the surface layer of the composite coating, that is, the sealing layer. The sealing layer should be evenly brushed and the dosage should be strictly controlled. Ensure that some holes are closed, and some hole channels are left, and the number of channels is controllable.

[0049] For the sealing layer, the number M...

Embodiment 1

[0060] The self-polishing anti-corrosion and anti-scaling coating is nickel-based alloy stainless steel at the bottom, zinc alloy at the middle layer, and organic sealing agent at the surface. The plasma thermal spraying method is sequentially prepared on the outer wall of the pipe string. The nickel-based alloy stainless steel layer has a dense structure, which can prevent the infiltration of corrosive media and play the role of isolation and corrosion resistance; the zinc alloy layer has a low potential and has the function of sacrificial anode. Electronics avoid the phenomenon of "big cathode and small anode"; the organic sealing agent layer can effectively seal most of the inherent pores on the surface of the coating, control the infiltration channel of corrosive media, and ensure the anti-corrosion effect.

[0061] The self-polishing anti-corrosion and anti-scaling coating design is a comprehensive application of the electrochemical sacrificial anode anti-corrosion mechan...

Embodiment 2

[0063] The self-polishing anti-corrosion and anti-fouling coating files are the bottom layer 13Cr stainless steel, the middle layer Al alloy, and the surface layer sealing agent. The supersonic thermal spraying method is sequentially prepared on the outer wall of the pipe string. The thermal spraying process is arc current 240A, arc voltage 32V, and spraying distance 150mm. The prepared composite coating has a dense structure, high density, and optimal corrosion resistance, with a corrosion rate of only 0.072mm / a.

[0064] Most of the pores on the surface of the self-polishing anti-corrosion and anti-fouling coating are sealed by the sealing agent, leaving only a small part of the inherent pores, which are evenly distributed on the coating surface. Under the corrosion conditions of oil and gas fields, the self-polishing anti-corrosion and anti-scaling coating is affected by the synergistic effect of corrosion / scaling, and the surface will undergo a "self-polishing" behavior of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com