Visible light-responsive N, B co-doped In2O3/TiO2 precursor, and preparation method and application thereof

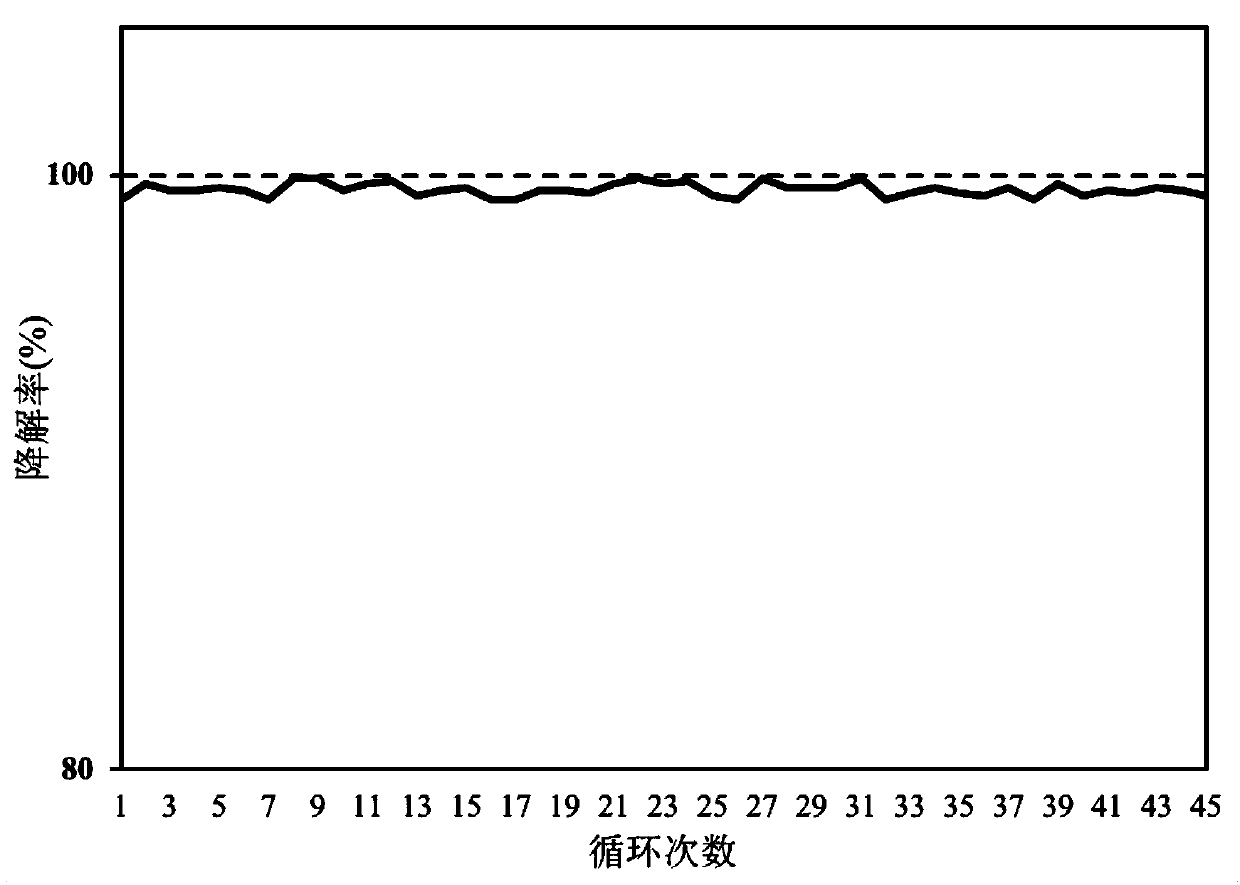

A precursor and co-doping technology, applied in the field of materials science, can solve the problems of low utilization rate of titanium dioxide, limited application of photocatalytic technology, uneven loading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this embodiment, the visible light responsive N, B co-doped In 2 o 3 / TiO 2 The precursor is synthesized as follows:

[0049] (1) Put 1 mol of tetrapropyl titanate, 120 g of polyethylene glycol and 7.57 g of indium nitrate in a drying reaction kettle equipped with a condenser tube and a drying tube, and heat the reaction under stirring at 100°C until the system is clear and transparent;

[0050] (2) At 100°C, add 0.3 mol of boric acid to the system, and keep it warm for 4 hours;

[0051] (3) At 95°C, add 0.5 mol of ethanolamine to the system, heat to 100°C, and keep warm for 4 hours;

[0052] (4) Adjust the temperature to 90° C., add 0.8 mol of acetylacetone, then drop in a mixture of 0.6 mol of water and 1.9 mol of n-propanol, reflux for 1 hour after dropping, and remove the solvent under reduced pressure after dropping the temperature to obtain the precursor.

[0053] The precursor has good solubility in any solvent or mixed solvent of ethanol, n-propanol, isop...

Embodiment 2

[0057] In this embodiment, the visible light responsive N, B co-doped In 2 o 3 / TiO 2 The precursor is synthesized as follows:

[0058] (1) Place 1 mol of tetraisopropyl titanate, 6.51 g of indium sulfate and 5 g of polymethyl methacrylate in a drying reaction kettle equipped with a condenser tube and a drying tube, and heat the reaction under stirring at 110°C until the system is clear and transparent;

[0059] (2) At 90°C, add 0.12 mol of ammonium borate to the system under stirring, and keep it warm for 3 hours;

[0060] (3) At 90°C, add 0.3 mol of ethanolamine to the system, and keep it warm for 4 hours;

[0061] (4) Adjust the temperature to 90° C., add 0.3 mol of ethyl acetoacetate, then drop in a mixture of 1.2 mol of water and 6 mol of isopropanol, reflux for 3 hours after dropping, and remove the solvent under reduced pressure to obtain the precursor.

[0062] The precursor has good solubility in any solvent or mixed solvent of ethanol, n-propanol, isopropanol, et...

Embodiment 3

[0067] In this embodiment, the visible light responsive N, B co-doped In 2 o 3 / TiO 2 The precursor is synthesized as follows:

[0068] (1) Place 1 mol of tetrabutyl titanate, 3.79 g of indium nitrate and 60 g of polypropylene glycol in a drying reactor equipped with a condenser tube and a drying tube, and heat the reaction under stirring at 100°C until the system is clear and transparent;

[0069] (2) At 70°C, add 0.24mol boric acid to the system under stirring, heat to 90°C, and keep it warm for 5 hours;

[0070] (3) At 60°C, add 2mol of acetamide to the system, heat to 120°C, and keep warm for 4h;

[0071] (4) Adjust the temperature to 80° C., add 0.5 mol of ethyl acetoacetate, then drop in a mixture of 1 mol of water and 2.5 mol of n-butanol, reflux for 2 hours after dropping, and remove the solvent under reduced pressure to obtain the precursor.

[0072] The precursor has good solubility in any solvent or mixed solvent of ethanol, n-propanol, isopropanol, ethylene gly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com