Oil-resistant silicone rubber and preparation method thereof

A technology of silicone rubber and fluorosilicone rubber, which is applied in the field of oil-resistant silicone rubber, can solve the problems of poor oil resistance, high temperature resistance, and high temperature resistance, and achieve stable physical and chemical properties, improve oil resistance, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

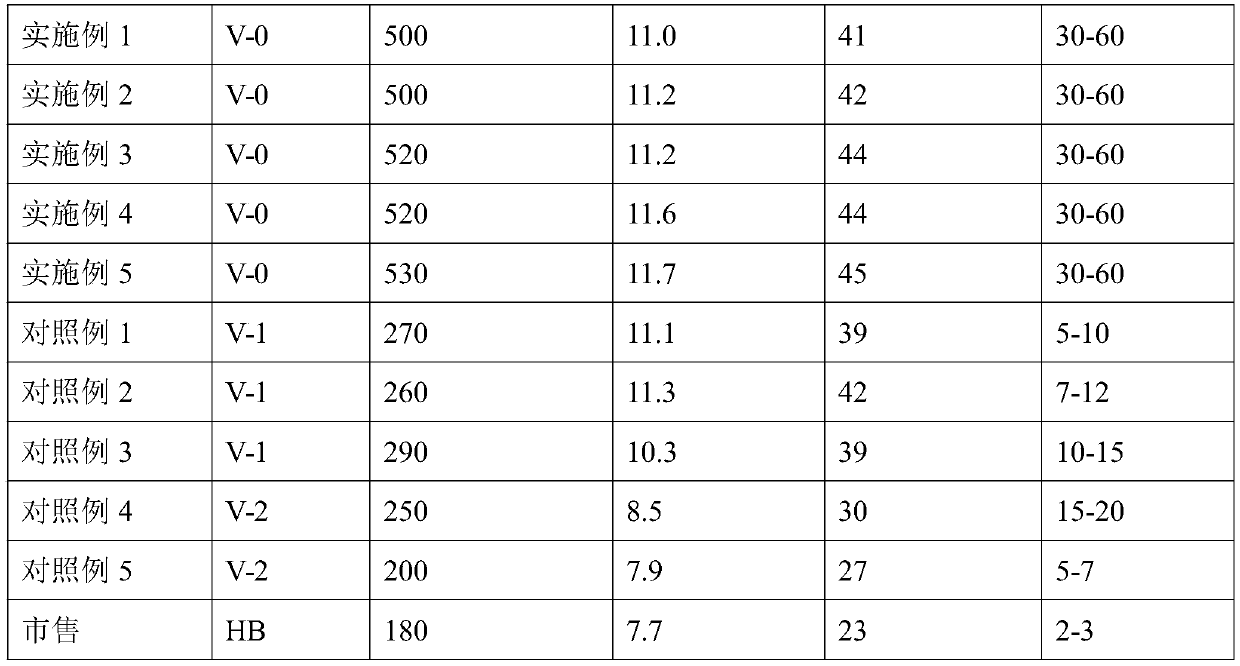

Examples

Embodiment 1

[0026] Raw material composition (parts by weight): 150 parts of silicone rubber, 10 parts of white carbon black, 50 parts of fluorosilicone rubber, 3 parts of hydroxyl silicone oil, 1 part of hydrogen-containing silicone oil, 5 parts of heat stabilizer, 20 parts of refractory filler, 3 parts of catalyst, 10 parts of aluminum hydroxide, 6 parts of oil resistance additive W5506 and 1 part of vulcanizing agent BP.

[0027] The catalyst is a catalyst with carbon black as a carrier and palladium, tungsten and platinum as active components, and the mass ratio of the palladium, tungsten, platinum and carbon black is 1:2:5:100;

[0028] Described refractory filler comprises quartz sand, mica powder, talcum powder and basalt, and mass ratio is 12:60:10:7;

[0029] The heat stabilizer includes calcium carbonate, magnesium stearate, calcium stearate, zinc oxide and phosphite, and the mass ratio is 55:12:12:7:2.

[0030] The silicone rubber is methylphenyl silicone rubber.

[0031] A me...

Embodiment 2

[0033] Raw material composition (parts by weight): 200 parts of silicone rubber, 20 parts of white carbon black, 80 parts of fluorosilicone rubber, 5 parts of hydroxyl silicone oil, 2 parts of hydrogen-containing silicone oil, 12 parts of heat stabilizer, 30 parts of refractory filler, 7 parts of catalyst, 15 parts of aluminum hydroxide, 10 parts of oil resistance additive W55000 and 3 parts of vulcanizing agent DBPMH.

[0034] The catalyst is a catalyst with carbon black as a carrier and palladium, tungsten and platinum as active components, and the mass ratio of the palladium, tungsten, platinum and carbon black is 1:2:5:100;

[0035] Described refractory filler comprises quartz sand, mica powder, talcum powder and basalt, and mass ratio is 12:60:10:7;

[0036] The heat stabilizer includes calcium carbonate, magnesium stearate, calcium stearate, zinc oxide and phosphite, and the mass ratio is 55:12:12:7:2.

[0037] The silicone rubber is methylphenyl silicone rubber.

[00...

Embodiment 3

[0040] Raw material composition (parts by weight): 160 parts of silicone rubber, 12 parts of white carbon black, 60 parts of fluorosilicone rubber, 3 parts of hydroxyl silicone oil, 1.2 parts of hydrogen-containing silicone oil, 7 parts of heat stabilizer, 22 parts of refractory filler, 4 parts of catalyst, 12 parts of aluminum hydroxide, 7 parts of oil resistance additive W5507 and 1 part of vulcanizing agent DCBP.

[0041] The catalyst is a catalyst with carbon black as a carrier and palladium, tungsten and platinum as active components, and the mass ratio of the palladium, tungsten, platinum and carbon black is 1:2:5:100;

[0042] Described refractory filler comprises quartz sand, mica powder, talcum powder and basalt, and mass ratio is 12:60:10:7;

[0043] The heat stabilizer includes calcium carbonate, magnesium stearate, calcium stearate, zinc oxide and phosphite, and the mass ratio is 55:12:12:7:2.

[0044] The silicone rubber is methyl vinyl silicone rubber.

[0045]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com