Sensor, preparation method and application thereof, and detection method of 2, 4, 6-trinitrophenol

A technology of trinitrophenol and a detection method, applied in the field of sensors, can solve the problems of low fluorescence efficiency, non-luminescence, low luminescence intensity, etc., and achieve the effects of simple process, low production cost and enhanced fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] In a second aspect, in at least one embodiment, a method for preparing the above-mentioned sensor is provided, comprising the following steps:

[0070] (a) adding the dispersion of nano metal rods to the surface of the substrate dropwise, and drying to obtain a substrate with a self-assembled nano metal rod array, the nano metal rod array is vertically self-assembled on the surface of the substrate;

[0071] (b) immersing the substrate obtained in step (a) in the molybdenum disulfide quantum dot dispersion, and after stirring, the molybdenum disulfide quantum dots are loaded on the nano metal rods to obtain the sensor;

[0072] Alternatively, the molybdenum disulfide quantum dot dispersion liquid is spin-coated on the substrate obtained in the step (a), and the molybdenum disulfide quantum dots are supported on nano metal rods to obtain the sensor.

[0073] The preparation method has simple process, low production cost, and is suitable for mass production. The prepared ...

Embodiment 1

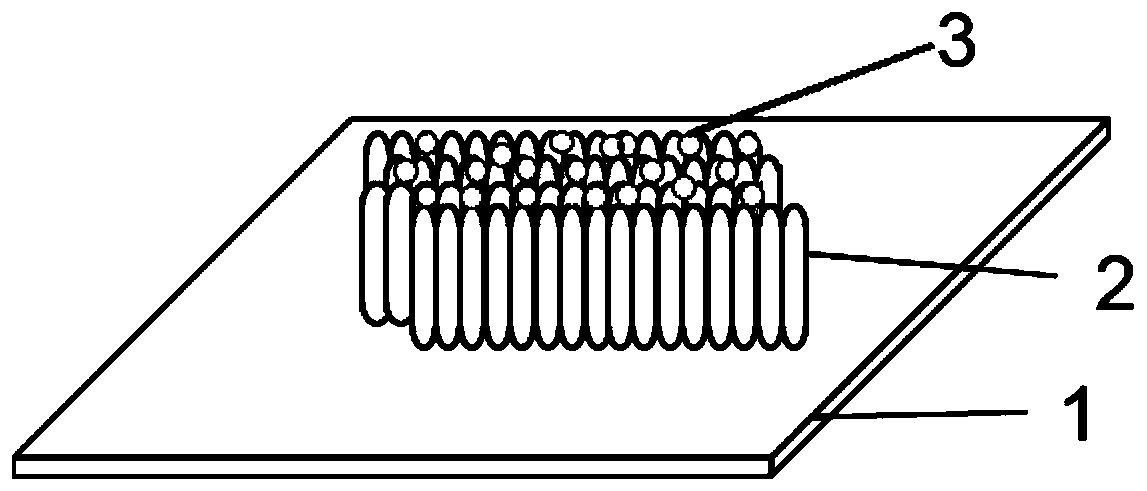

[0095] a sensor such as figure 1 As shown, it includes a substrate 1, an array of nano-gold rods 2 vertically distributed on the surface of the substrate, and molybdenum disulfide quantum dots 3 supported on the tips of the nano-gold rods; wherein, the length of the prepared nano-gold rods is less than 10 nm, and the absorption peak is located at 920 nm. The distance between the gold rods is not more than 1nm, the resonance peak of the nano gold rod array is located at 650-750nm, and the molybdenum disulfide quantum dot has a single-layer structure with an average diameter of 3nm.

[0096] The preparation method of the sensor comprises the following steps:

[0097] (a) The preparation of nano-gold dispersion liquid adopts "seed crystal method", including: chloroauric acid (25mM, 100μL), freshly prepared iced sodium borohydride (10mM, 600μL), hexadecyltrimethyl Ammonium bromide (CTAC) (0.2M, 5mL) was added into a 20mL beaker and kept for 0.5h to obtain a brown gold nano single...

Embodiment 2

[0106] A sensor comprising a substrate, an array of gold nanorods vertically distributed on the surface of the substrate, and molybdenum disulfide quantum dots loaded on the tips of the gold nanorods; wherein, the length of the gold nanorods prepared is less than 8nm, and the absorption peak is located at 920nm. The distance between them is not more than 1nm, the resonance peak of the nano-gold rod array is located at 650-750nm, and the molybdenum disulfide quantum dot has a single-layer structure with an average diameter of 2nm.

[0107] The difference between the preparation method of this sensor and Example 1 is that the concentration of chloroauric acid in Example 1 is replaced by 20 mM, and the treatment time of molybdenum disulfide powder in the ultrasonic cleaning machine is replaced by 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com