Ultrasonic-mediated silk fibroin composite collagen hydrogel and preparation method thereof

A technology of collagen hydrogel and silk fibroin, which is applied in the field of ultrasound-mediated silk fibroin composite collagen hydrogel and its preparation, can solve the problem of narrow adjustable range of structure and performance, troubles for researchers to innovate, and limited application range, etc. problem, to achieve the effect of efficient and quick preparation method, easy industrialization and popularization and application, and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

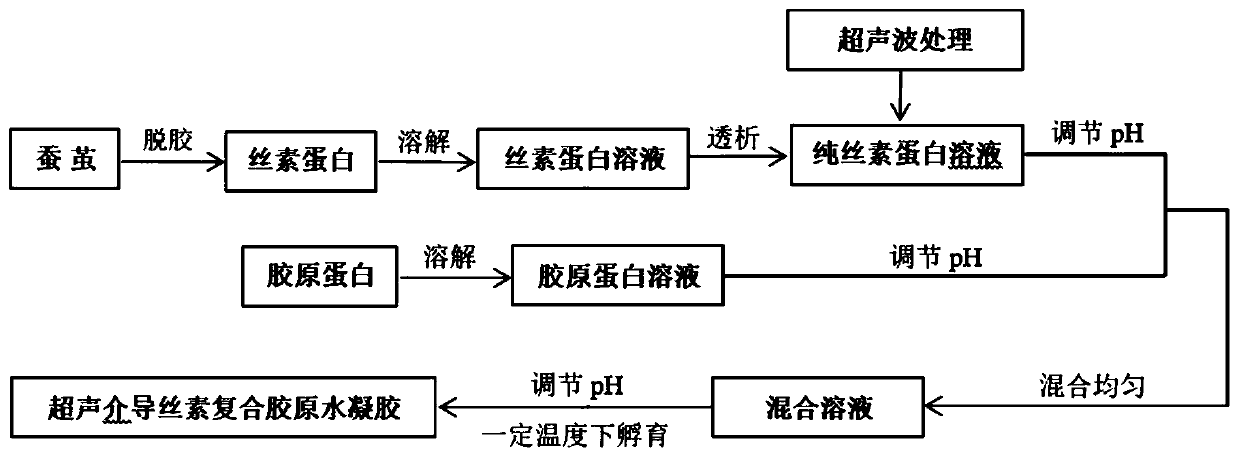

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Preparation of ultrasound-mediated silk fibroin composite collagen hydrogel

[0040] (1) Dissolve 0.45g of collagen completely in 1M 100mL acetic acid solution at 2-8°C, adjust the pH value to 7.0, and obtain a uniform collagen solution for use.

[0041] (2) Dissolve 10g degummed silk in CaCl 2 / C 2 h 5 OH / H 2 O (n=1:2:8) ternary solution, dissolved at 75±2°C for 4 hours, and then dialyzed in deionized water for 3 days with a dialysis bag with a molecular weight cut-off of 3500Da to obtain a concentration of 5% (w / The silk fibroin solution of v) is diluted to a concentration of 3% (w / v) with deionized water for subsequent use;

[0042] (3) Measure 50mL of the 5% silk fibroin solution prepared in step (2), use ultrasonic power of 1000 watts, ultrasonic power ratio of 40% and normal temperature to ultrasonically treat the silk fibroin solution for 1min, and then place it in 2-8 Stand-by at ℃;

[0043] (4) Measure 20mL of collagen solution and 10mL of silk...

Embodiment 2

[0045] Example 2 Preparation of ultrasound-mediated silk fibroin composite collagen hydrogel

[0046] (1) Dissolve 1 g of collagen completely in 0.3M 200mL acetic acid solution at 2-8°C, adjust the pH value to 5.0, and obtain a uniform collagen solution for use.

[0047] (2) 10g degummed silk was dissolved in 9.3M LiBr solution, dissolved at 60±5°C for 4h, and after the dissolution was complete, it was dialyzed in deionized water for 3 days with a molecular weight cut-off of 1000Da to obtain a concentration of 3% (w / v ) of the silk fibroin solution and adjust the pH to 5 for stand-by;

[0048] (3) Measure 30 mL of the 3% silk fibroin solution prepared in step (2), treat the silk fibroin solution for 10 seconds with an ultrasonic power of 500 watts, an ultrasonic power ratio of 60% and normal temperature, and then place it in 2-8 Stand-by at ℃;

[0049] (4) Measure 30mL collagen solution and 10mL silk fibroin solution in turn from (1) and (3) and mix them well to form a mixed...

Embodiment 3

[0050] Example 3 Ultrasound-mediated preparation of silk fibroin composite collagen hydrogel

[0051] (1) Dissolve 8g of collagen completely in 0.3M 200mL acetic acid solution at 2-8°C, adjust the pH value to 5.0, and obtain a uniform collagen solution for use.

[0052] (2) 15g degummed silk was dissolved in 40% CaCl 2 In the solution, dissolve at 98±2°C for 4 hours. After the dissolution is complete, use a dialysis bag with a molecular weight cut-off of 12,000 Da to dialyze in deionized water for 3 days to obtain a silk fibroin solution with a concentration of 8% (w / v) and adjust the pH to 5. stand-by;

[0053] (3) Measure 50 mL of the 8% silk fibroin solution prepared in step (2), process the silk fibroin solution for 30 seconds with an ultrasonic power of 500 watts, an ultrasonic power ratio of 60% and an ice bath for 30 seconds, and then place it in 2- Stand-by at 8°C;

[0054] (4) Measure 10mL of collagen solution and 10mL of silk fibroin solution from (1) and (3) in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com