System for removing heat-stable salt in organic amine liquid and method

An organic amine liquid and organic amine technology, which are applied in the field of organic amine liquid purification, can solve the problems of difficulty in removing cations, large consumption of chemical agents, and large discharge of waste liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

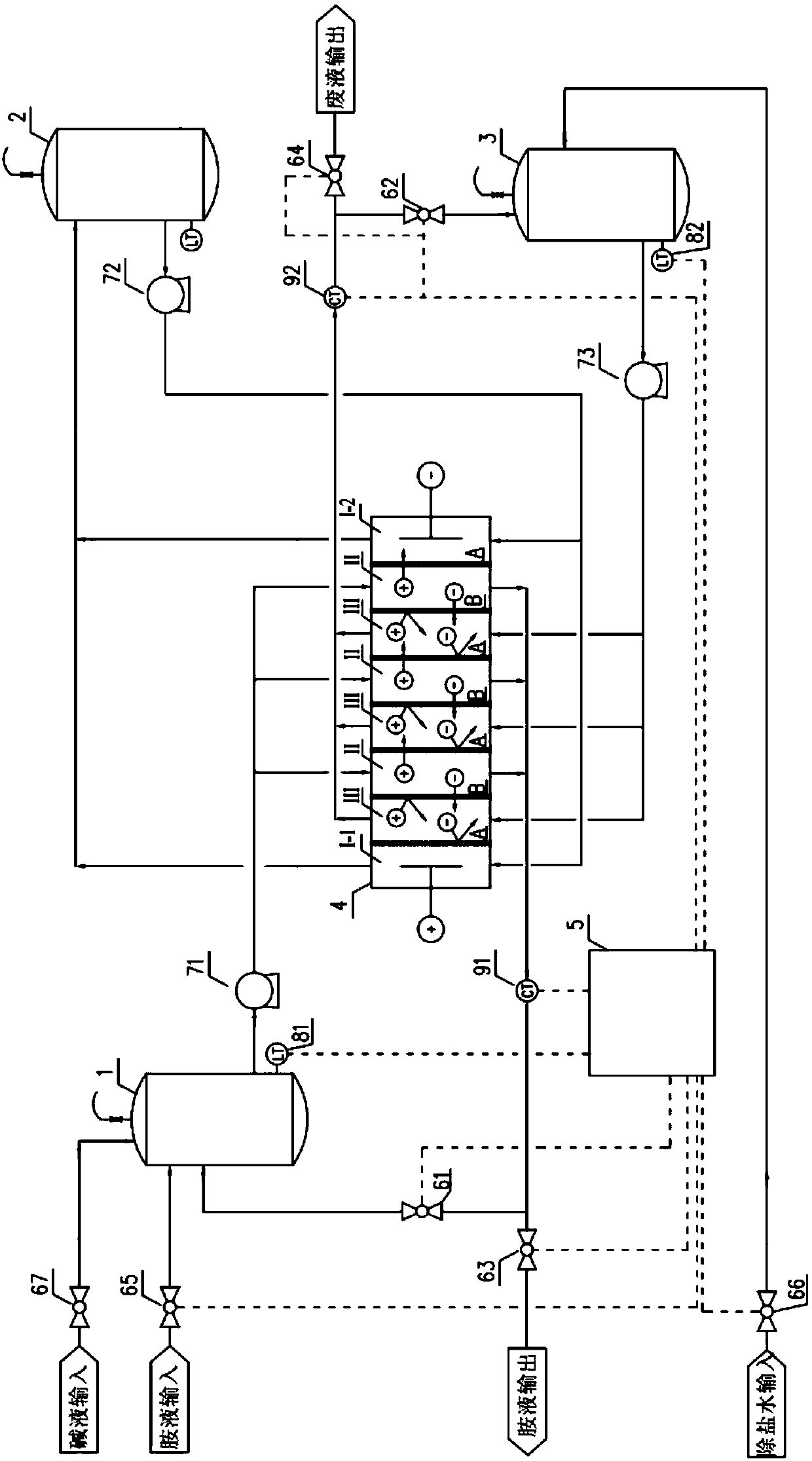

[0070] The system for removing heat-stable salts in organic amine liquids provided in this example is a skid-mounted system, and its structural diagram is as follows figure 1 As shown, the system includes: an organic amine liquid storage device 1, an electrode liquid storage device 2, a demineralized water storage device 3, a membrane stack 4 and a control center 5, wherein the membrane stack 4 is respectively connected to the organic amine liquid storage device 1. The electrode liquid storage device 2 and the demineralized water storage device 3; the membrane stack 4 is provided with at least one organic amine liquid inlet, organic amine liquid outlet, waste liquid inlet, waste liquid outlet, electrode liquid inlet and electrode liquid outlet; the outlet of the organic amine liquid and the outlet of the waste liquid are respectively provided with a first conductivity meter 91 and a second conductivity meter 92 for monitoring the outlet of the organic amine liquid and the outle...

Embodiment 2

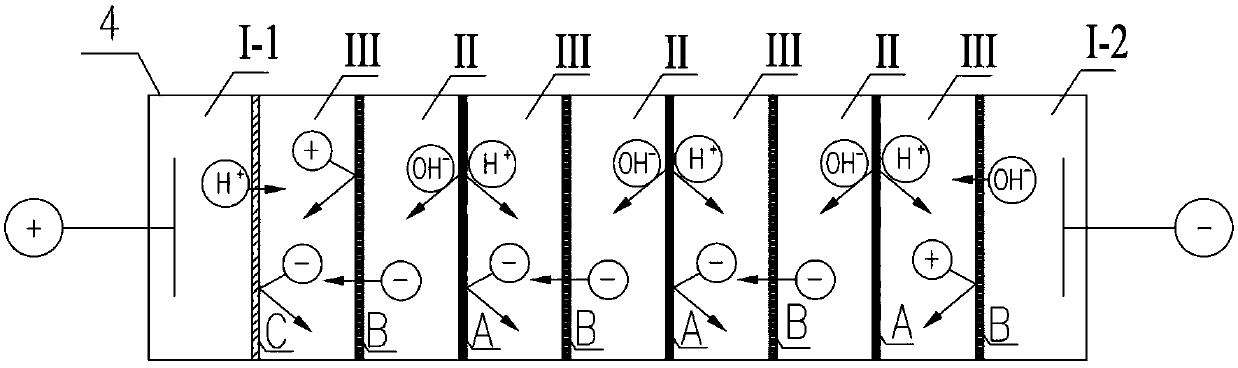

[0088] The system for removing heat-stable salts in organic amine liquids provided in this example and the method for treating organic amine liquids containing heat-stable salts using the system for removing heat-stable salts in organic amine liquids are as in Example 1, except that , the membrane stack 4 is a bipolar membrane stack, and its structural schematic diagram and working principle are as follows figure 2 As shown, the first ion exchange membrane A is a bipolar membrane, the second ion exchange membrane B is an anion exchange membrane, and the bipolar membrane stack includes 100 sets of bipolar membranes and anion membranes arranged alternately periodically. The exchange membrane and the third ion exchange membrane C, the third ion exchange membrane C is a cation exchange membrane, which is arranged close to the anode plate, and from the third ion exchange membrane C to the direction of the cathode plate, the module includes in turn Multiple anion exchange membranes...

Embodiment 3

[0094] The system for removing heat-stable salts in organic amine liquids provided in this example and the method for treating organic amine liquids containing heat-stable salts using the system for removing heat-stable salts in organic amine liquids are as in Example 1, except that , the system is also provided with an lye input device, and the liquid outlet of the lye input device is connected with the organic amine liquid inlet of the membrane stack 4 . The lye is sodium hydroxide, and the concentration of the lye is 30% by weight.

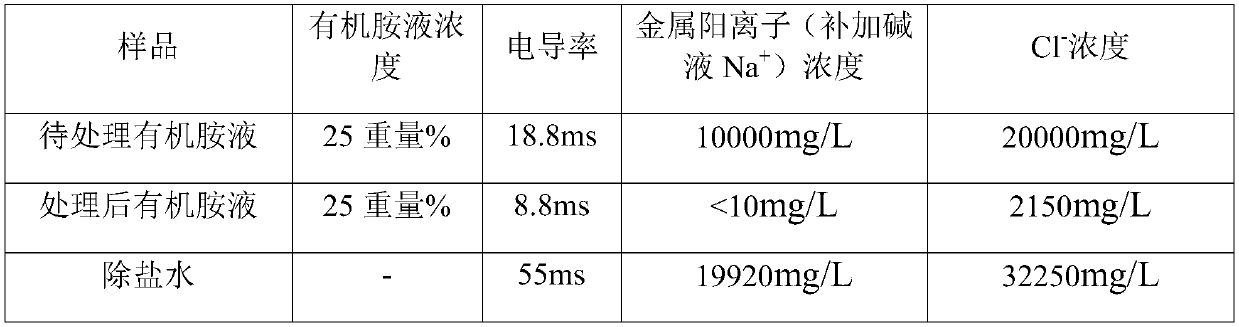

[0095] The organic amine solution to be treated is an organic amine solution prepared by industrial pure MDEA (hydrochloric acid is added to the amine solution). Show.

[0096] table 3

[0097]

[0098] It can be seen from Table 3 that after the treatment, the conductivity of the organic amine solution decreases, the concentration of sodium ions, chloride ions and heat-stable salt decreases, while the conductivity of desalted water increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com