Copper-cobalt-sulfur nanosheet array/molybdenum foil composite material and preparation method and application thereof

A nanosheet array and composite material technology, applied in the field of micro-nano material preparation, can solve the problems of small specific surface area, low electron transport performance, and few catalytic active sites of transition metal sulfides, and achieve good electrochemical performance and catalytic performance , Improve the electron transmission rate, good practical application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

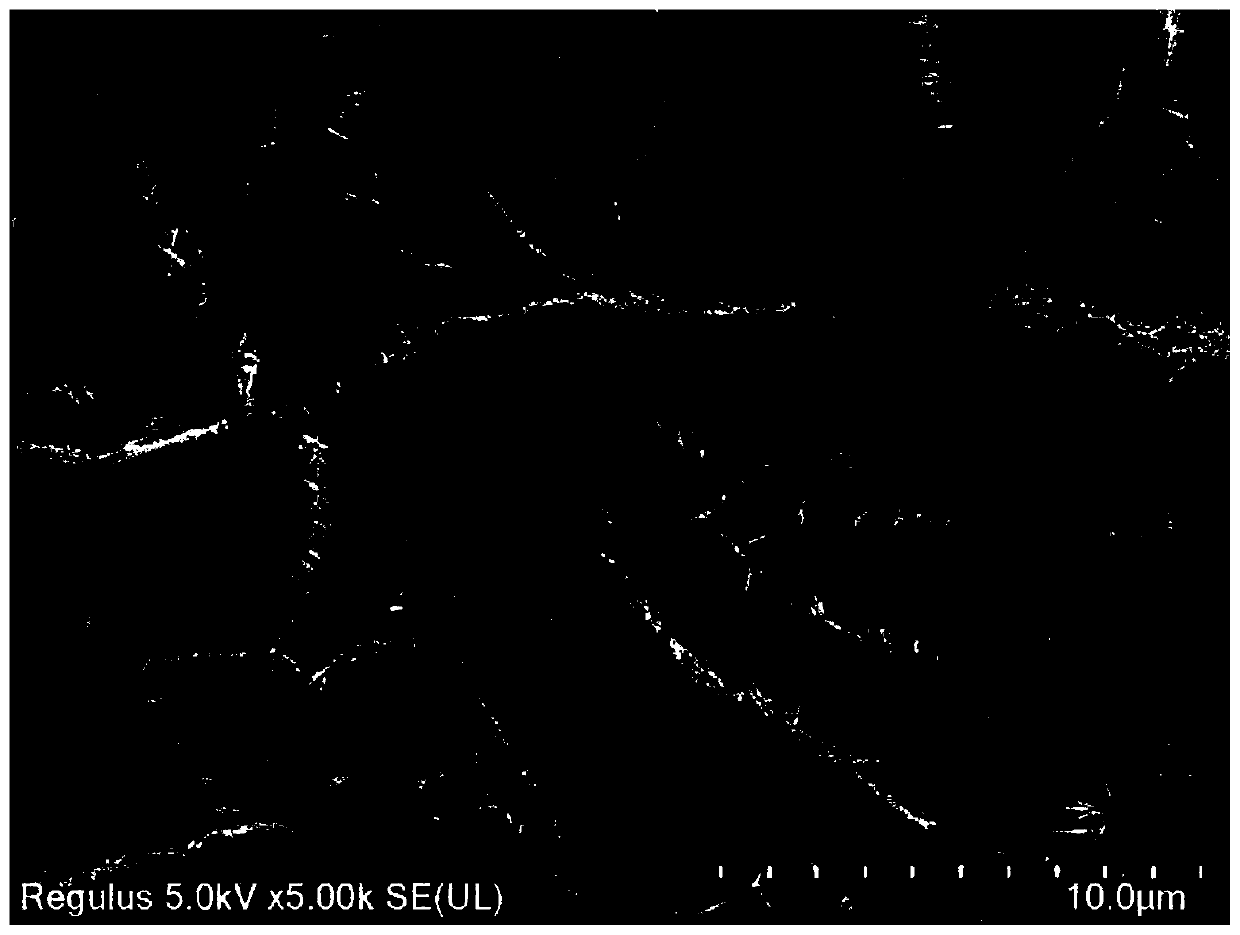

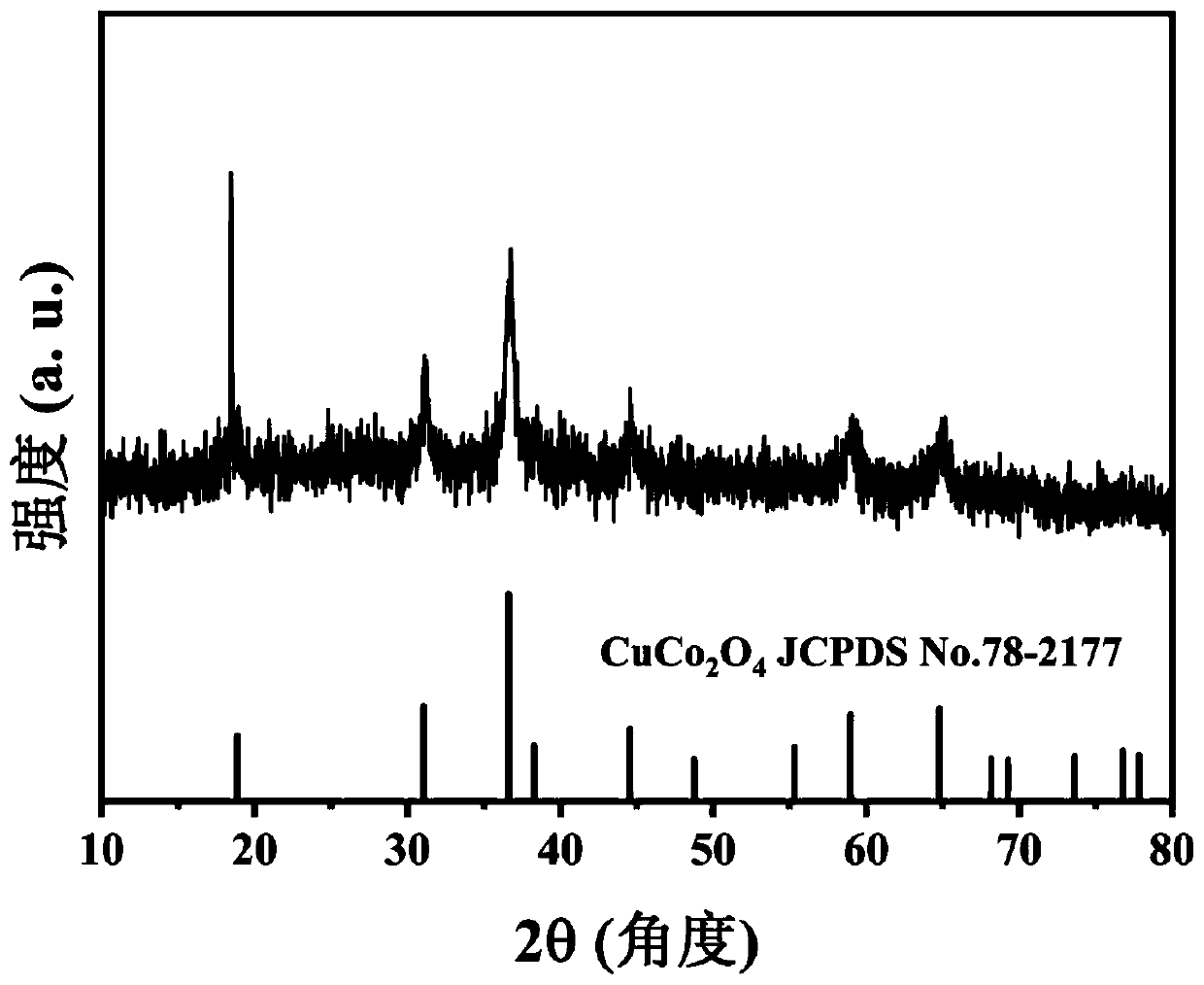

[0043] A method for preparing a copper-cobalt-sulfur nanosheet array / molybdenum foil composite material, comprising the following steps:

[0044] (1) Sonicate the molybdenum foil with a size of 1cm×4cm for 5 minutes with deionized water and ethanol to clean the surface dirt, then place the cleaned molybdenum foil at 60°C for 5 hours in vacuum and set aside.

[0045] (2) Weigh 0.5mmol cobalt nitrate hexahydrate, 0.5mmol copper nitrate trihydrate and 2mmol urea, add 30mL deionized water in turn, stir until the three are completely dissolved, and obtain a uniform solution; transfer the solution to the tetrafluoroethylene lining Put the molybdenum foil treated in step (1) into the solution, close the reaction kettle, put it into a blast oven, and heat it at a constant temperature for 6 hours at 100°C; after the reaction is completed, take out the molybdenum foil Wash 5 times with deionized water and ethanol respectively;

[0046] (3) Put the molybdenum foil treated in step (2) in...

Embodiment 2

[0054] A method for preparing a copper-cobalt-sulfur nanosheet array / molybdenum foil composite material, comprising the following steps:

[0055] (1) Sonicate the molybdenum foil with a size of 1cm×4cm with deionized water and ethanol for 5 minutes respectively to clean the surface dirt, and then vacuum-dry the cleaned molybdenum foil at 60°C for 5h, and set aside.

[0056] (2) Weigh 1mmol cobalt nitrate hexahydrate, 0.5mmol copper nitrate trihydrate and 3mmol urea, add 50mL deionized water successively, stir until the three are completely dissolved, and obtain a uniform solution; transfer the solution to a tetrafluoroethylene-lined Put the molybdenum foil treated in step (1) into the solution in the high-pressure reactor, close the reactor, put it in a blast oven, and heat it at a constant temperature for 5 hours at 120°C; after the reaction is completed, take out the molybdenum foil Wash 5 times with deionized water and ethanol respectively;

[0057] (3) Put the molybdenum ...

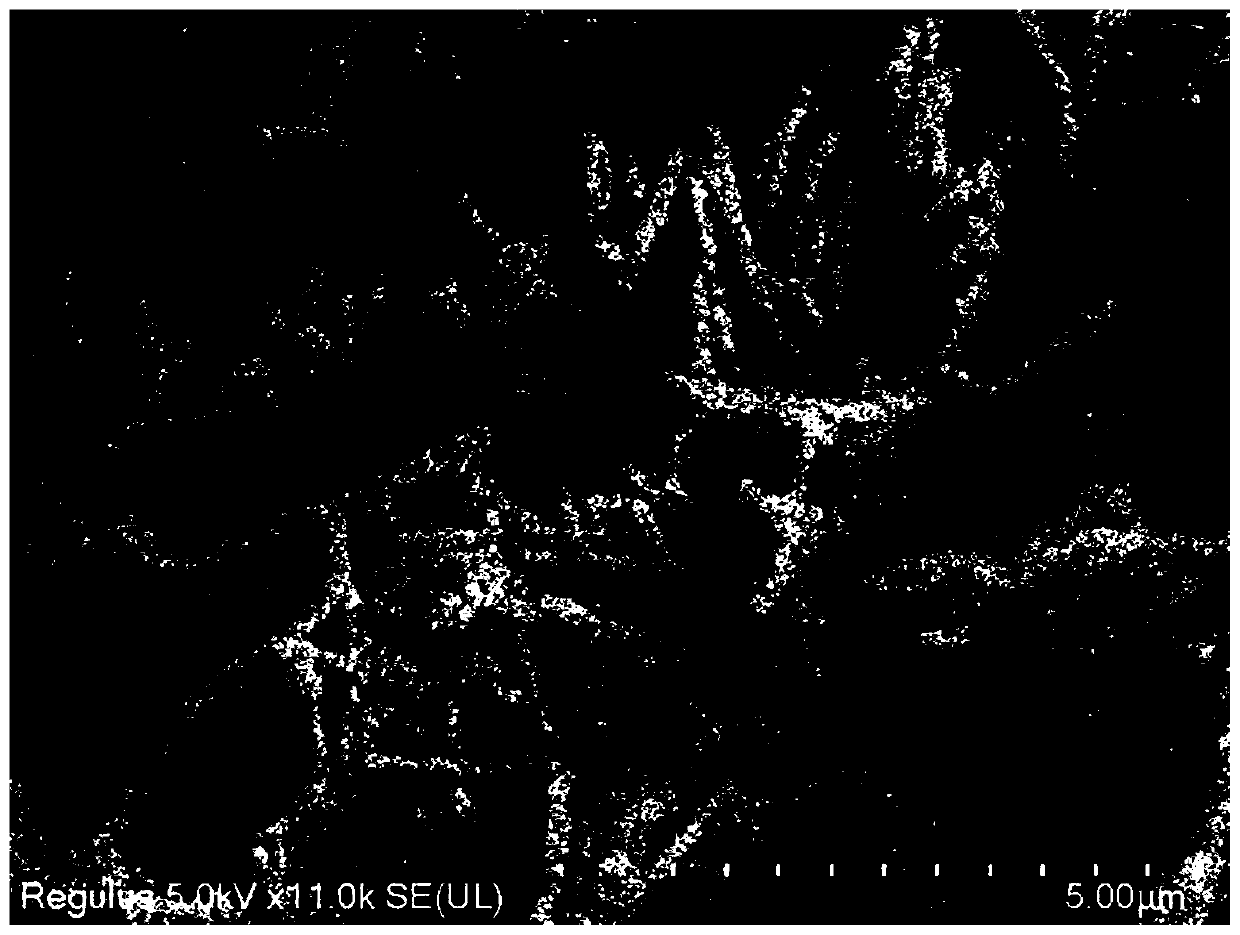

Embodiment 3

[0062] A method for preparing a copper-cobalt-sulfur nanosheet array / molybdenum foil composite material, comprising the following steps:

[0063] (1) Sonicate the molybdenum foil with a size of 2cm×4cm for 5 minutes with deionized water and ethanol respectively to clean the surface dirt, and then vacuum-dry the cleaned molybdenum foil at 60°C for 5h, and set aside.

[0064] (2) Weigh 4.5mmol cobalt nitrate hexahydrate, 1.5mmol copper nitrate trihydrate and 5mmol urea, add 50mL deionized water in turn, stir until the three are completely dissolved, and obtain a uniform solution; transfer the solution to the tetrafluoroethylene lining Put the molybdenum foil treated in step (1) into the solution, close the reaction kettle, put it into a blast oven, and heat it at a constant temperature for 8 hours at 80°C; after the reaction, take out the molybdenum foil Wash 5 times with deionized water and ethanol respectively;

[0065] (3) Put the molybdenum foil treated in step (2) into a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com