Environment-friendly resource utilization process and system for waste oil drum as hazardous waste

A hazardous waste and recycling technology, which is applied in the field of environmental protection and resource utilization technology and system of hazardous waste waste oil drums, can solve the problems such as failure to realize hazardous waste recycling, lack of pollution prevention and control facilities, and inability to guarantee hazardous characteristics, etc. The effect of eliminating hazardous waste characteristics, eliminating environmental risks, eliminating hazardous characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

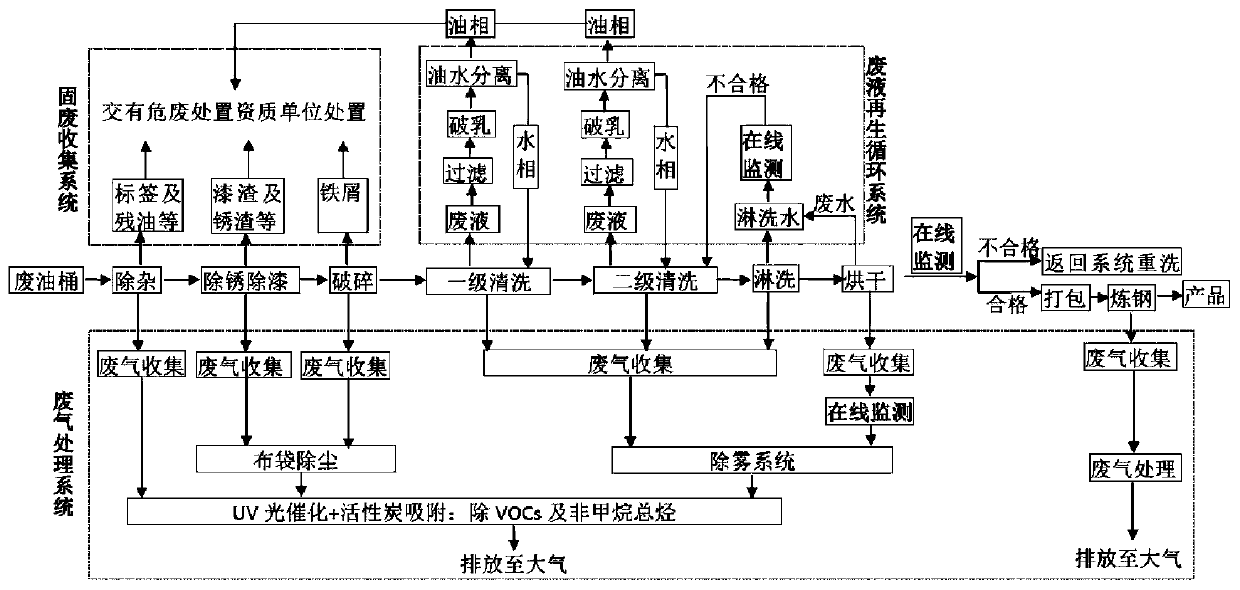

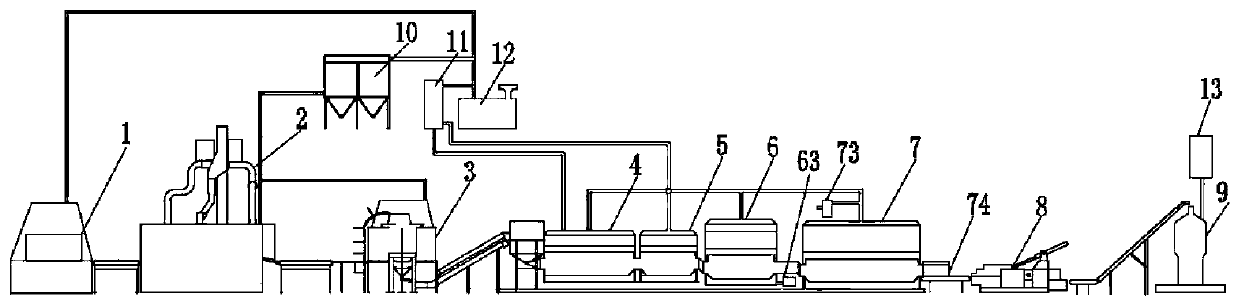

[0042] Such as figure 1 As shown in , a process for the environmental protection and resource utilization of hazardous waste waste oil barrels, the specific steps are as follows:

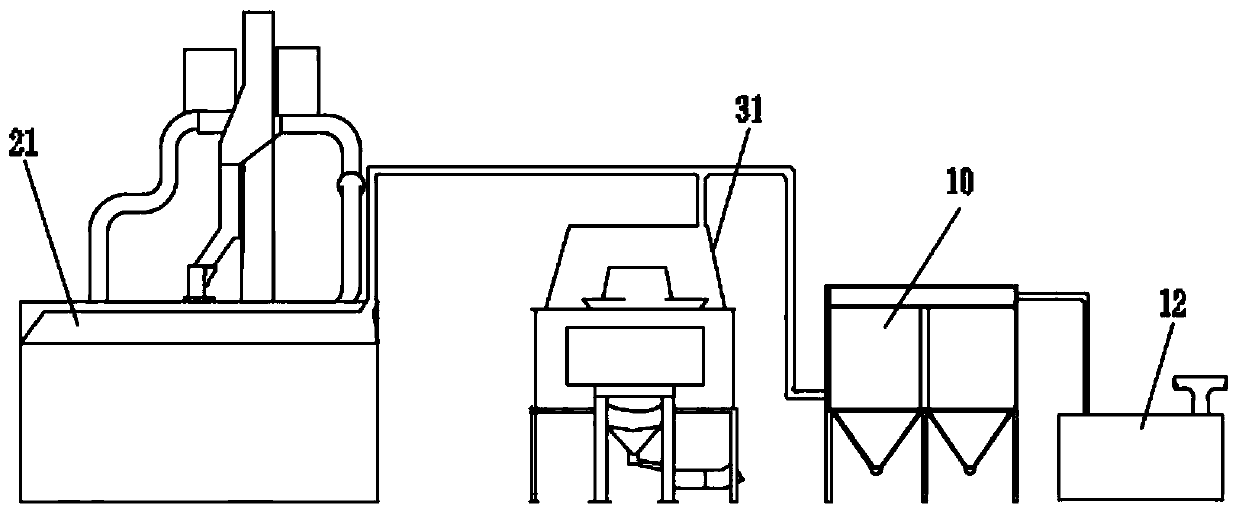

[0043] (1) Impurity removal: remove non-metallic impurities on the surface of waste oil drums, clean up residual waste oil on the inner surface, collect the waste gas generated through the gas collection system, use UV photocatalysis and activated carbon adsorption technology to remove non-methane total hydrocarbon organic gases and discharge them up to standard ;

[0044] (2) Rust removal and paint removal: Use shot blasting to hit the outer surface of the oil drum to remove rust and paint impurities, collect the generated exhaust gas through the gas collection system, use a dust collector to remove solid impurities, and then use UV photocatalysis and activated carbon adsorption processes to remove rust and paint impurities. Methane and total hydrocarbon organic gases are discharged after reaching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com