Silane coupling agent modified silicon dioxide phase change microcapsule and preparation method thereof

A silane coupling agent, phase change microcapsule technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of complex process, leakage of core material, poor water resistance of microcapsules, etc. Water resistance and effect of improving coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

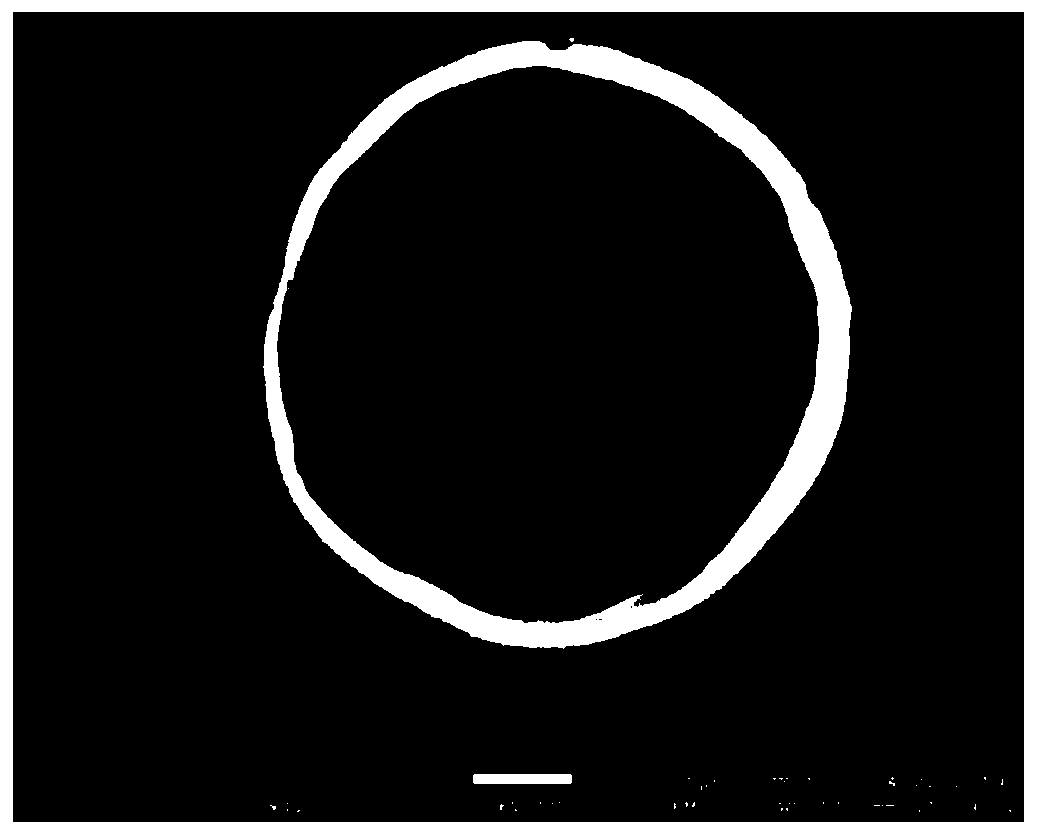

[0028] The preparation method of the silicon dioxide phase-change microcapsules modified by the silane coupling agent of the present invention comprises the following steps:

[0029] (1) Preparation of silica precursor solution

[0030] Prepare a sodium silicate aqueous solution, then add an alkyl triethoxysilane coupling agent and anhydrous ethanol and stir evenly for use, wherein by mass ratio, sodium silicate:modifier:alkyl triethoxysilane: Water=(7~10):(1~3):10:90;

[0031] (2) Preparation of phase change emulsion

[0032] The phase change material, emulsifier and dilute hydrochloric acid solution with a mass fraction of 10% are prepared and heated according to the mass ratio (5-10):0.5:(28-37). After the core material is completely melted, mechanically stir at 1000-1400rad / Emulsify at min speed to form phase change emulsion;

[0033] (3) Preparation of modified phase change microcapsules

[0034] Under mechanical stirring, add the silica precursor solution in step (1...

Embodiment 1

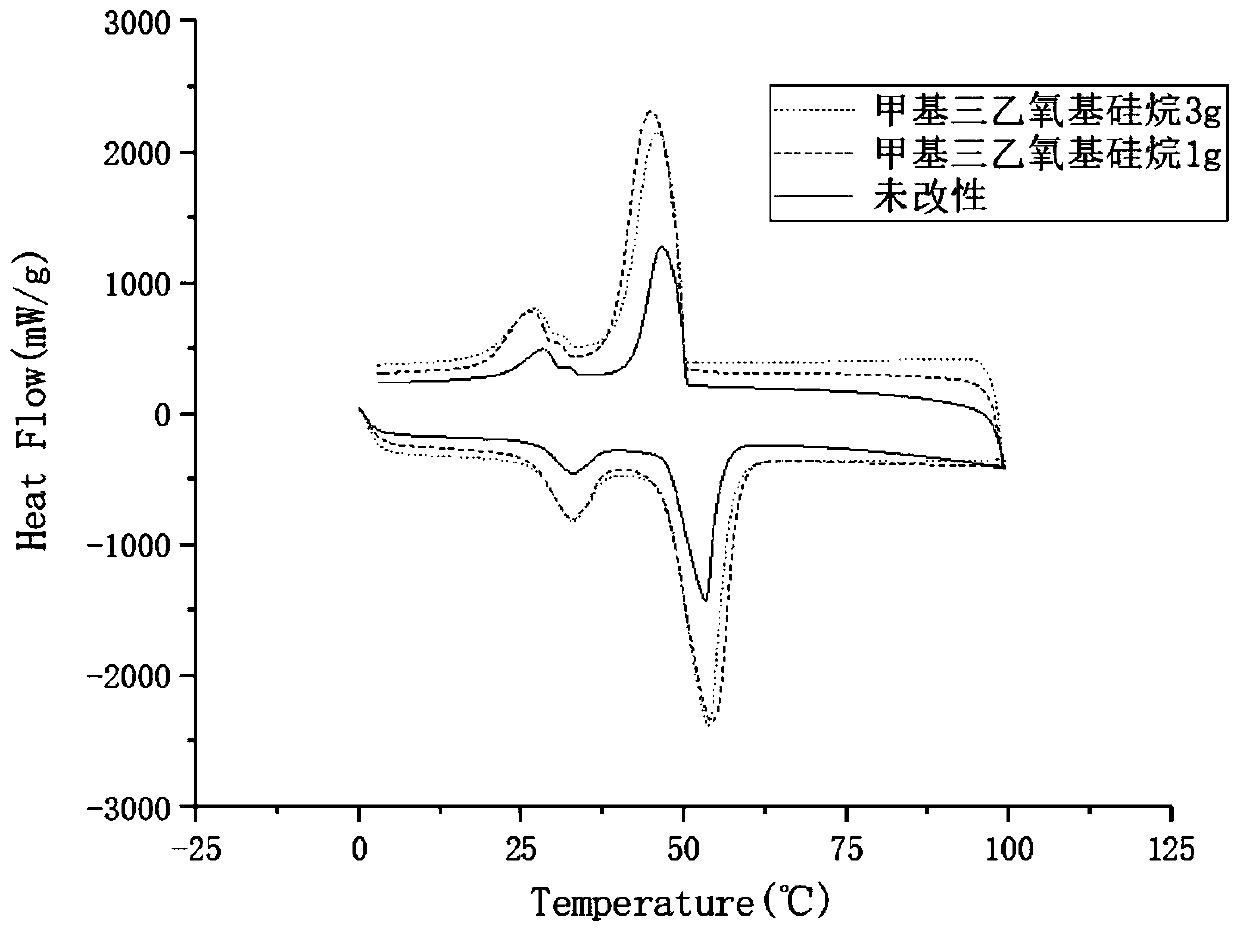

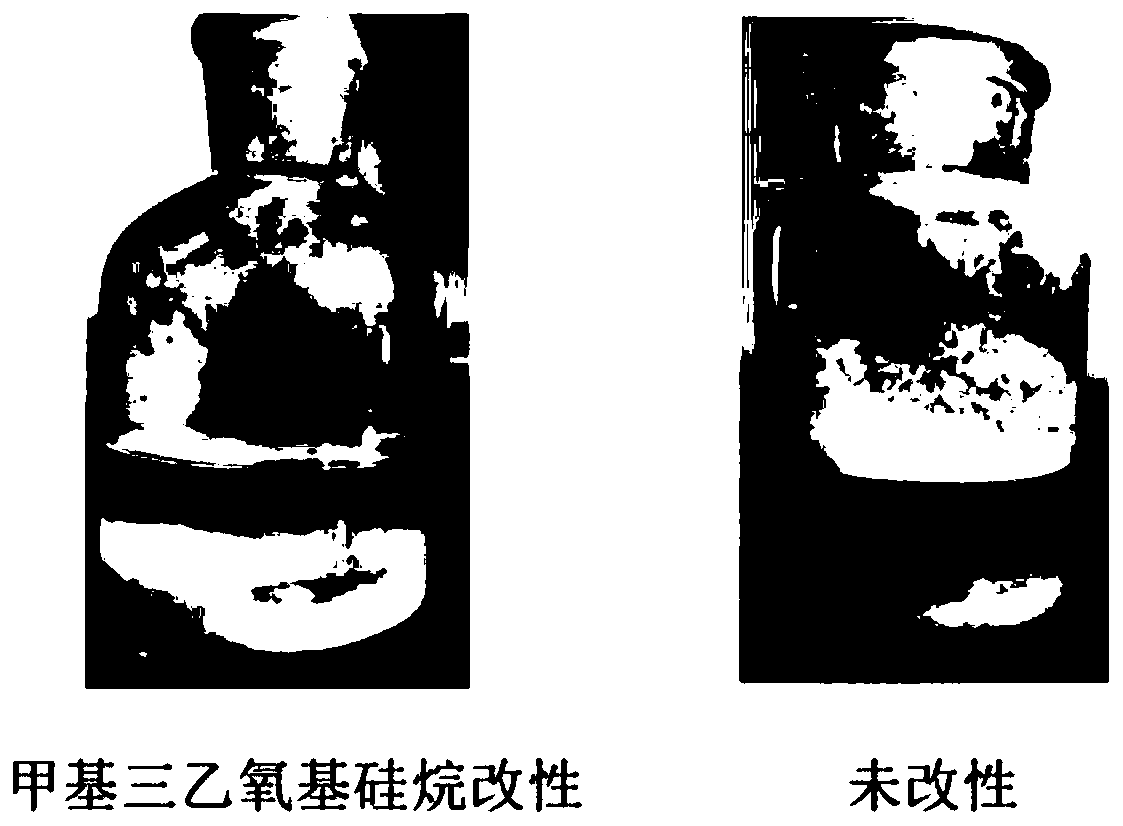

[0042] Taking the phase change material paraffin as the core material, sodium silicate as the silicon source, and methyltriethoxysilane as the modifier, the dosage is 33.3% of the mass of the sodium silicate as an example.

[0043] Take 7.5g and add 100g water to prepare a solution, add methyltrioxysilane and absolute ethanol and stir for 20min to prepare component A for use, wherein the distribution ratio of each component is sodium silicate: methyltriethoxysilane : absolute ethanol: water = 7.5: 2.5: 10: 90;

[0044] 10g of paraffin, 0.4g of cetyltrimethylammonium bromide (CTAB) and 0.2g of polyoxyethylene octylphenol ether-10 (op-10), and 30g of dilute hydrochloric acid solution are added to the three-necked flask and heated. After the core material is completely melted, the phase change material emulsion is formed after 1000rad / min mechanical stirring for 30min;

[0045] Adjust the mechanical stirring of the phase-change emulsion to 400 rad / min, heat the water bath at 65°...

Embodiment 2

[0047] The phase-change material stearic acid is used as the core material, sodium silicate is used as the silicon source, methyltriethoxysilane is used as the modifier, and the dosage is 33.3% of the mass of sodium silicate, and poloxamer P407 is used as the non-ionic surface active agent as an example.

[0048] The preparation of the silicon dioxide precursor solution was the same as in Example 1, and it was prepared as component A for use.

[0049] Add 7.5 g of stearic acid, 0.4 g of cetyltrimethylammonium bromide (CTAB) and 0.2 g of poloxamer P407, and 30 g of dilute hydrochloric acid solution into a three-necked flask for heating. After the core material is completely melted, it is mechanically stirred at 1000rad / min for 30min to form a phase change material emulsion.

[0050] Adjust the mechanical stirring of the phase-change emulsion to 400rad / min and then heat it. Add component A dropwise into the phase-change material emulsion with a dropping funnel for 30 minutes. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com