Preparation method of flame-retardant wood-plastic wallboard

A technology for wood-plastic wallboard and wood board, which is applied in the direction of wood treatment, wood heating, humidity-conditioning wood, etc. Reduced swell, natural smooth woody feel, enhanced interaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

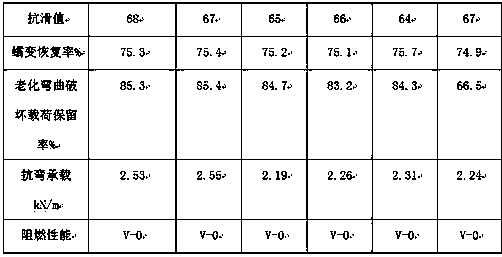

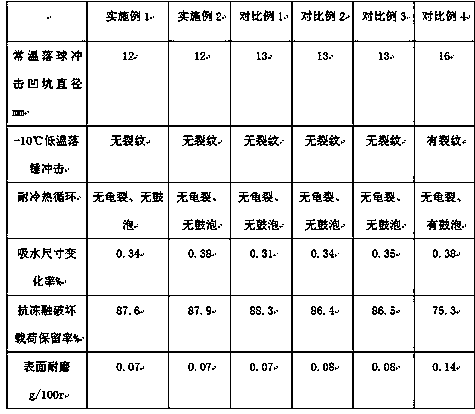

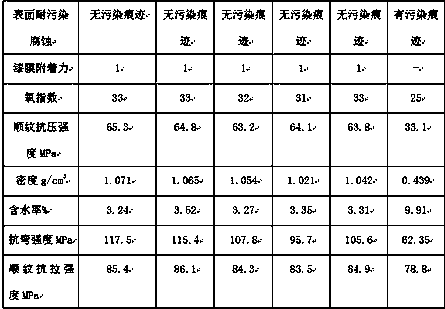

Examples

Embodiment 1

[0019] A method for preparing a flame-retardant wood-plastic wallboard, comprising the following steps:

[0020](1) Flame surface treatment: Treat the surface of the loose sheet with the blue flame of methane for 3 times, and the flame temperature is controlled at 1000°C, so that the flame surface of the sheet is smooth and deburred to form a treatment layer. The treatment layer is located on the outermost surface and has a lot of looseness (2) Washing: Spray the surface of the treatment layer with 7% dilute acid in the form of a spray, and keep the treatment layer facing up, and let it stand for 1 (3) Wetting: use 0.7% sodium α-olefin sulfonate solution in the form of spray to spray on the surface of the treatment layer of the board, and keep the treatment layer facing up, Let it stand for 0.5 hours to wet the surface of the board; (4) Diffusion treatment: add 1.3 parts of sodium dodecylbenzenesulfonate to 100 parts of alcohol solution with a mass fraction of 17% boron triflu...

Embodiment 2

[0028] A method for preparing a flame-retardant wood-plastic wallboard, comprising the following steps:

[0029] (1) Flame surface treatment: use methane blue flame to treat the surface of the loose plate 6 times, and the flame temperature is controlled at 1400°C, so that the flame surface of the plate is smooth and deburred to form a treatment layer. The treatment layer is located on the outermost surface and has a lot of porosity (2) Washing: Spray the surface of the plate treatment layer with 5% dilute acid in the form of a spray, and keep the treatment layer facing up, and let it stand for 0.5 hours , so that dilute acid penetrates into the interior of the board; (3) Wetting: Spray the surface of the treatment layer of the board with a 0.5% sodium α-olefin sulfonate solution in the form of a spray, and keep the treatment layer upward, statically Set aside for 0.1 hour to wet the surface of the board; (4) Diffusion treatment: Add 1.1 parts of sodium dodecylbenzenesulfonate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com