Modified polypropylene composite material for pipeline, and preparation method and application of modified polypropylene composite material

A composite material and polypropylene technology, which is applied in the field of modified polypropylene composite materials for pipelines and their preparation, can solve the problems of not being able to have flame retardancy, antistatic and mechanical properties at the same time, and achieve improved toughness, low processing energy consumption, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] A preparation method of a modified polypropylene composite material for pipelines, the method comprising:

[0051] Polypropylene, ethylene-vinyl acetate copolymer, EPDM rubber, unsaturated carboxylic acid graft copolymer of polyolefin elastomer, phosphogypsum whiskers, decabromodiphenylethane treated with supercritical carbon dioxide, super Nano antimony trioxide treated with critical carbon dioxide, silane coupling agent, dicumyl peroxide, micro-nano organically modified montmorillonite treated with supercritical carbon dioxide, micro-nano flake graphite treated with supercritical carbon dioxide, 1,1 , 3-three (2-methyl-4-hydroxyl-5-tert-butylphenyl) butane, 2-mercaptobenzimidazole, light stabilizer GW-944 and calcium stearate are mixed uniformly in parts by weight, and The uniformly mixed material is extruded and pelletized by a twin-screw extruder equipped with a micro-nano laminated stretching device, and then cooled, pelletized, dried, and packaged to obtain the pr...

Embodiment 1

[0060] A preparation method for a modified polypropylene composite material for pipelines, comprising:

[0061] 100Kg polypropylene, 1Kg ethylene-vinyl acetate copolymer, 1Kg EPDM rubber, 10Kg polyolefin elastomer unsaturated carboxylic acid graft copolymer, 10Kg supercritical carbon dioxide treated phosphogypsum whiskers, 8Kg supercritical Decabromodiphenylethane treated with carbon dioxide, 2Kg nano antimony trioxide treated with supercritical carbon dioxide, 0.5Kg silane coupling agent, 2Kg dicumyl peroxide, 3Kg micro-nano organic modified montmorillonite treated with supercritical carbon dioxide Soil, 6Kg supercritical carbon dioxide treated micronano flake graphite, 0.5Kg 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane, 0.5Kg 2-mercaptobenzo Imidazole, 0.5Kg light stabilizer GW-944, and 0.5Kg calcium stearate are mixed uniformly in a mixer.

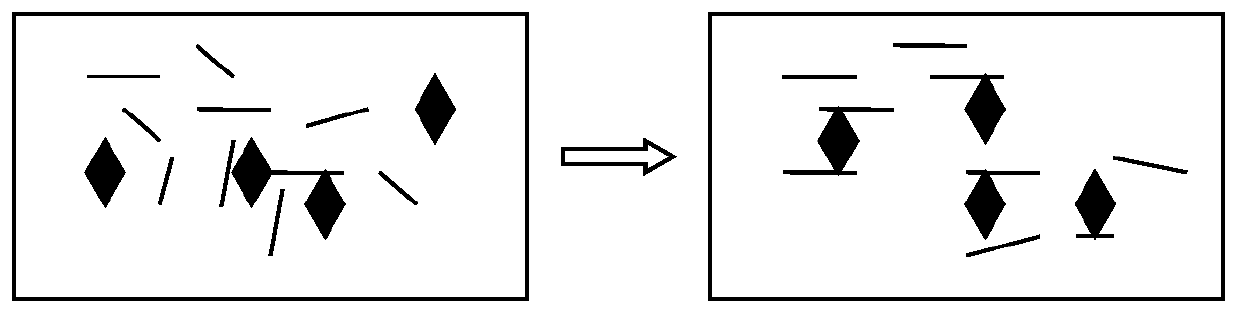

[0062] Then, see figure 1 , the uniformly mixed material is extruded and granulated by a twin-screw extruder equipped wit...

Embodiment 2

[0075] A preparation method of a modified polypropylene composite material for pipelines, which is basically the same as the preparation method of Example 1, the difference is that the content of each component is 100Kg polypropylene, 6Kg ethylene-vinyl acetate copolymer, 6Kg EPDM Rubber, 20Kg unsaturated carboxylic acid graft copolymer of polyolefin elastomer, 10Kg supercritical carbon dioxide treated phosphogypsum whiskers, 9Kg supercritical carbon dioxide treated decabromodiphenylethane, 3Kg supercritical carbon dioxide treated nano trioxide Diantimony, 1Kg silane coupling agent, 6Kg dicumyl peroxide, 5Kg micro-nano organic modified montmorillonite treated with supercritical carbon dioxide, 6Kg micro-nano flake graphite treated with supercritical carbon dioxide, 0.6Kg 1,1, 3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane, 0.6Kg 2-mercaptobenzimidazole, 0.6Kg light stabilizer GW-944, 0.5Kg calcium stearate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com