Anti-cracking plastic pipe and preparation method thereof

A plastic pipe and anti-cracking technology, applied in the field of plastic pipe processing, can solve problems such as affecting the service life of plastic pipes and breaking of plastic pipes, and achieve the effects of enhancing the use value, preventing long-term cracks, and enhancing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

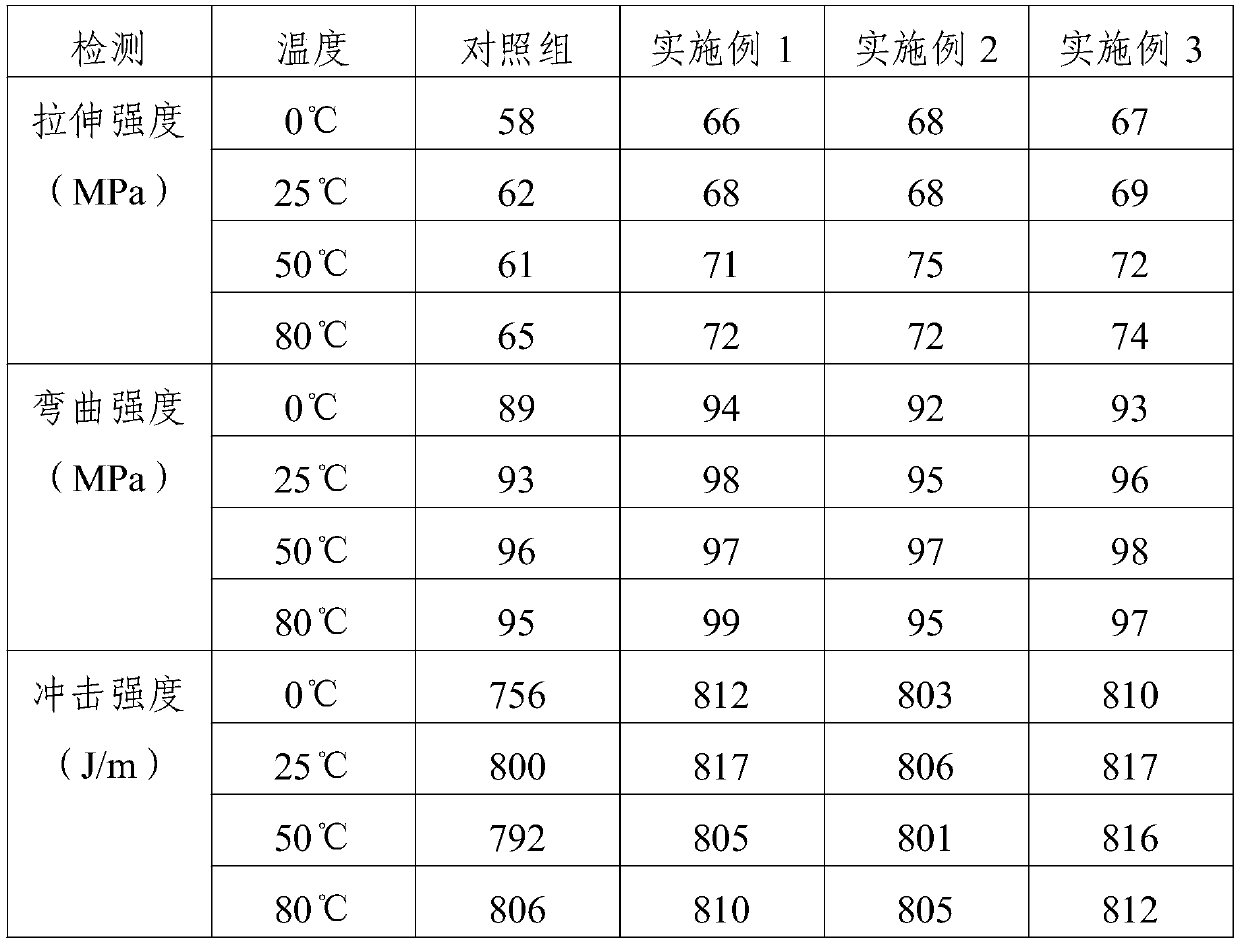

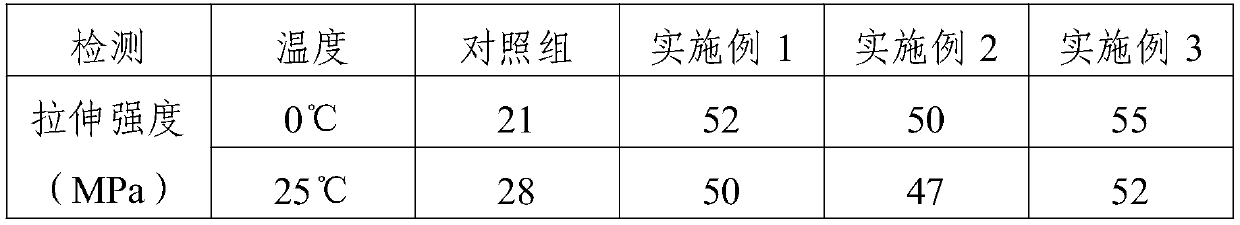

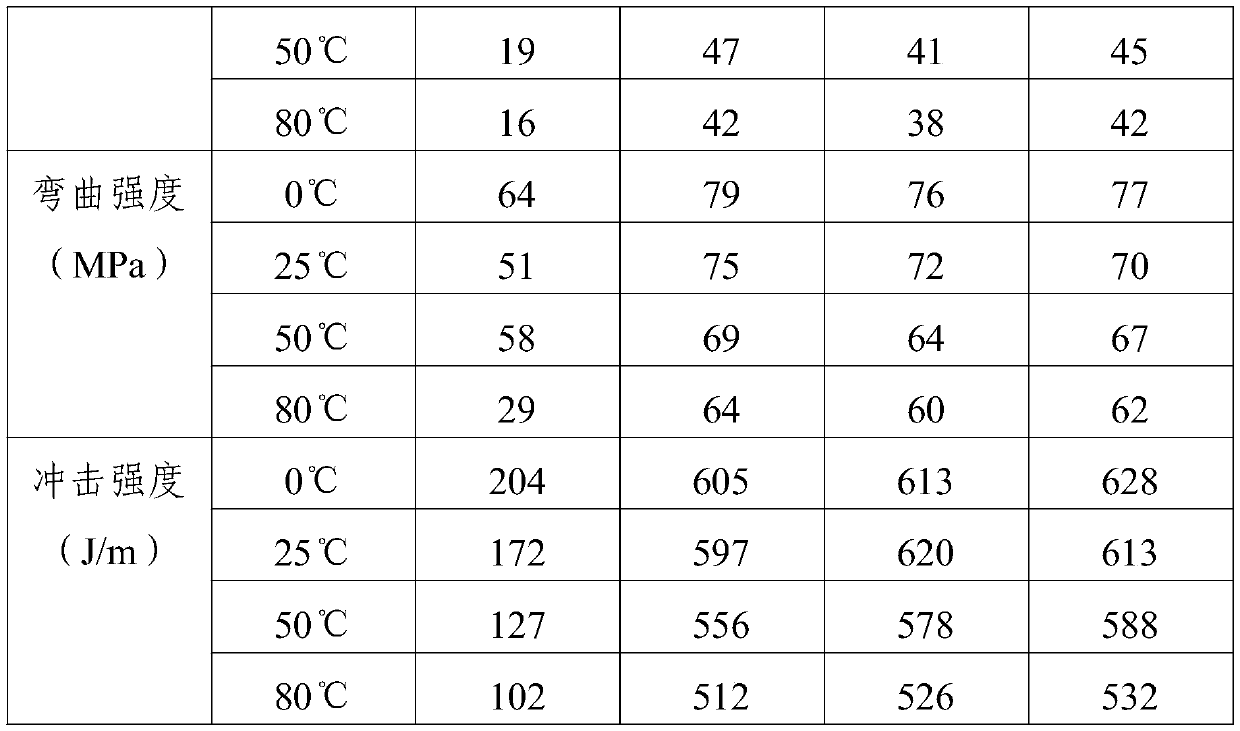

Examples

Embodiment 1

[0029] An anti-cracking plastic pipe, the anti-cracking plastic pipe is made of the following raw materials in parts by weight: 46 parts of polycarbonate, 15 parts of phenolic resin, 10 parts of low-density polyethylene, and 1 part of dodecane dibasic acid diester , 4 parts of bisphenol A cyanate, 1 part of o-chlorophenyl isocyanate, 4 parts of carbon fiber, 1 part of nano-silica, 1 part of ethyl cellulose, 1 part of compatibilizer, diphenylmethane diisocyanate 0.6 parts, 0.8 parts of hexamethylphosphoric triamide, 3 parts of composite antioxidant, 0.6 parts of ethylene oxide, 1.6 parts of castor oil, 1 part of plasticizer, 1 part of γ-aminoethylaminopropyl trimethoxysilane share.

[0030] The composite antioxidant is 2,5-di-tert-butyl hydroquinone, styrenated phenol, tert-butyl hydroquinone, N-phenyl-β-naphthylamine and ethyl acetate in a mass ratio of 2:1 : 1: 2: 4 mixture, its mixing preparation method is:

[0031] (1) Add N-phenyl-β-naphthylamine to ethyl acetate, stir e...

Embodiment 2

[0043]An anti-cracking plastic pipe, the anti-cracking plastic pipe is made of the following raw materials in parts by weight: 58 parts of polycarbonate, 18 parts of phenolic resin, 12 parts of low-density polyethylene, 3 parts of dodecane dibasic acid diester , 8 parts of bisphenol A cyanate, 2 parts of o-chlorophenyl isocyanate, 6 parts of carbon fiber, 2 parts of nano-silica, 2 parts of ethyl cellulose, 1.2 parts of compatibilizer, diphenylmethane diisocyanate 1.2 parts, 1.4 parts of hexamethylphosphoric triamide, 5 parts of composite antioxidant, 1.2 parts of ethylene oxide, 2.4 parts of castor oil, 2 parts of plasticizer, 1.2 parts of γ-aminoethylaminopropyl trimethoxysilane share.

[0044] The composite antioxidant is 2,5-di-tert-butyl hydroquinone, styrenated phenol, tert-butyl hydroquinone, N-phenyl-β-naphthylamine and ethyl acetate in a mass ratio of 2:1 : 1: 2: 4 mixture, its mixing preparation method is:

[0045] (1) Add N-phenyl-β-naphthylamine to ethyl acetate, ...

Embodiment 3

[0057] An anti-cracking plastic pipe, the anti-cracking plastic pipe is made of the following raw materials in parts by weight: 53 parts of polycarbonate, 16.5 parts of phenolic resin, 11 parts of low-density polyethylene, 2 parts of dodecane dibasic acid diester , 6 parts of bisphenol A cyanate, 1.5 parts of o-chlorophenylisocyanic acid, 5 parts of carbon fiber, 1.5 parts of nano silicon dioxide, 1.5 parts of ethyl cellulose, 1.1 parts of compatibilizer, diphenylmethane 0.9 parts of diisocyanate, 1.1 parts of hexamethylphosphoric triamide, 4 parts of composite antioxidant, 0.9 parts of ethylene oxide, 2 parts of castor oil, 1.5 parts of plasticizer, γ-aminoethylaminopropyl trimethoxy 1.1 parts of silane.

[0058] The composite antioxidant is 2,5-di-tert-butyl hydroquinone, styrenated phenol, tert-butyl hydroquinone, N-phenyl-β-naphthylamine and ethyl acetate in a mass ratio of 2:1 : 1: 2: 4 mixture, its mixing preparation method is:

[0059] (1) Add N-phenyl-β-naphthylamine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com