Angioma gel containing amphiphilic polymers and preparation method of angioma gel

An amphiphilic polymer and hemangioma technology, which is applied in the field of hemangioma gel containing amphiphilic polymers and its preparation, can solve the problems of adverse reactions, high blood drug concentration, unfavorable use of infant patients, etc., and achieve Ease of use, lower blood pressure, and enhanced antiviral ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

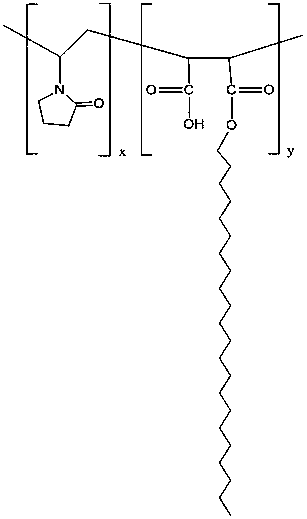

[0028] The preparation of amphiphilic polymer NVP-maleic acid monodocosanol monoester copolymer is carried out according to the following steps:

[0029] (1) Mix maleic anhydride and docosanol at a molar ratio of 1:0.7, stir magnetically at 50°C, react for 4 hours, cool to room temperature, and use methanol and water to mix at a volume ratio of 1:5 100mL, rinse the reaction product, remove excess unreacted maleic anhydride, and dry to obtain behenyl maleate;

[0030] (2) Take 0.005g of the initiator dimethyl azobisisobutyrate, 1g of N-vinylpyrrolidone and 1g of maleic acid monodocosanol monoester obtained in step (1), add 100mL of n-heptane, and Protection, mechanical stirring at 50°C, white precipitate NVP-maleic acid monodocosanol monoester copolymer was obtained.

Embodiment 2

[0032] (1) Mix maleic anhydride and docosanol at a molar ratio of 1.3:1, stir magnetically at 80°C, react for 7 hours, cool to room temperature, and use methanol and water at a volume ratio of 5:9. 260mL, rinse the reaction product, remove excess unreacted maleic anhydride, and dry to obtain behenyl maleate;

[0033](2) Take 0.1g of the initiator dimethyl azobisisobutyrate, 8g of N-vinylpyrrolidone and 4g of behenyl maleate monoester obtained in step (1), add 400mL of n-heptane, and Protection, mechanical stirring at 90°C, white precipitate NVP-maleic acid monodocosanol monoester copolymer was obtained.

Embodiment 3

[0035] (1) Mix maleic anhydride and docosanol at a molar ratio of 1.2:0.9, stir magnetically at 50-80°C, react for 6 hours, cool to room temperature, and mix methanol and water at a volume ratio of 3:7 Mixed solution 150mL, wash reaction product, remove excess unreacted maleic anhydride, dry, obtain behenyl maleate;

[0036] (2) Take 0.06g of the initiator dimethyl azobisisobutyrate, 5g of N-vinylpyrrolidone and 2.5g of behenyl maleate obtained in step (1), add 250mL of n-heptane, and Nitrogen protection, mechanical stirring at 75°C, a white precipitate of NVP-maleic acid monodocosanol monoester copolymer was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com