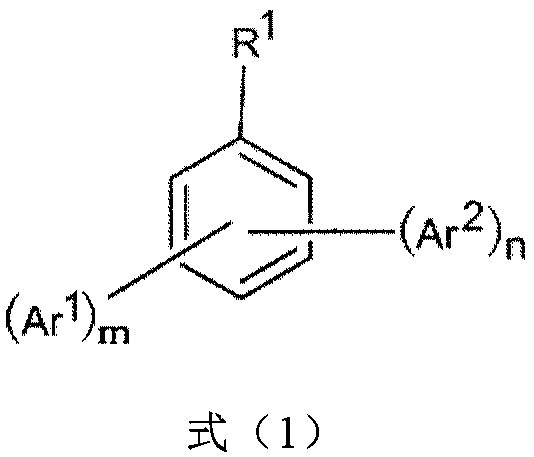

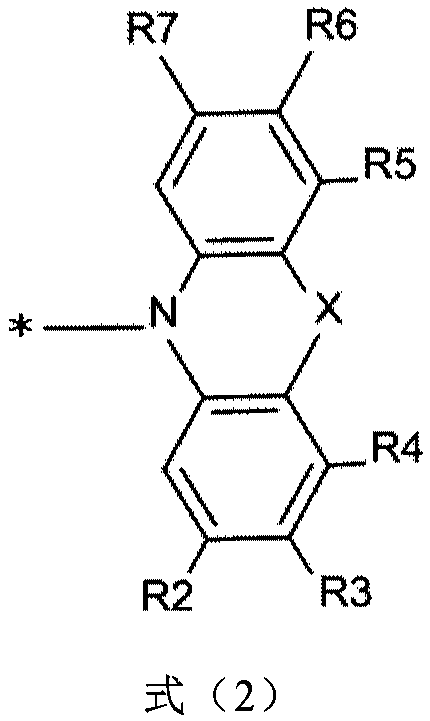

Organic electroluminescence material and application thereof

An organic compound and selected technology, applied in the fields of luminescent materials, organic chemistry, circuits, etc., can solve the problems of lower product cost, expensive materials, and efficiency roll-off, etc., and achieve device life improvement, reduce energy quenching, and efficiency roll-off. reduced effect

- Summary

- Abstract

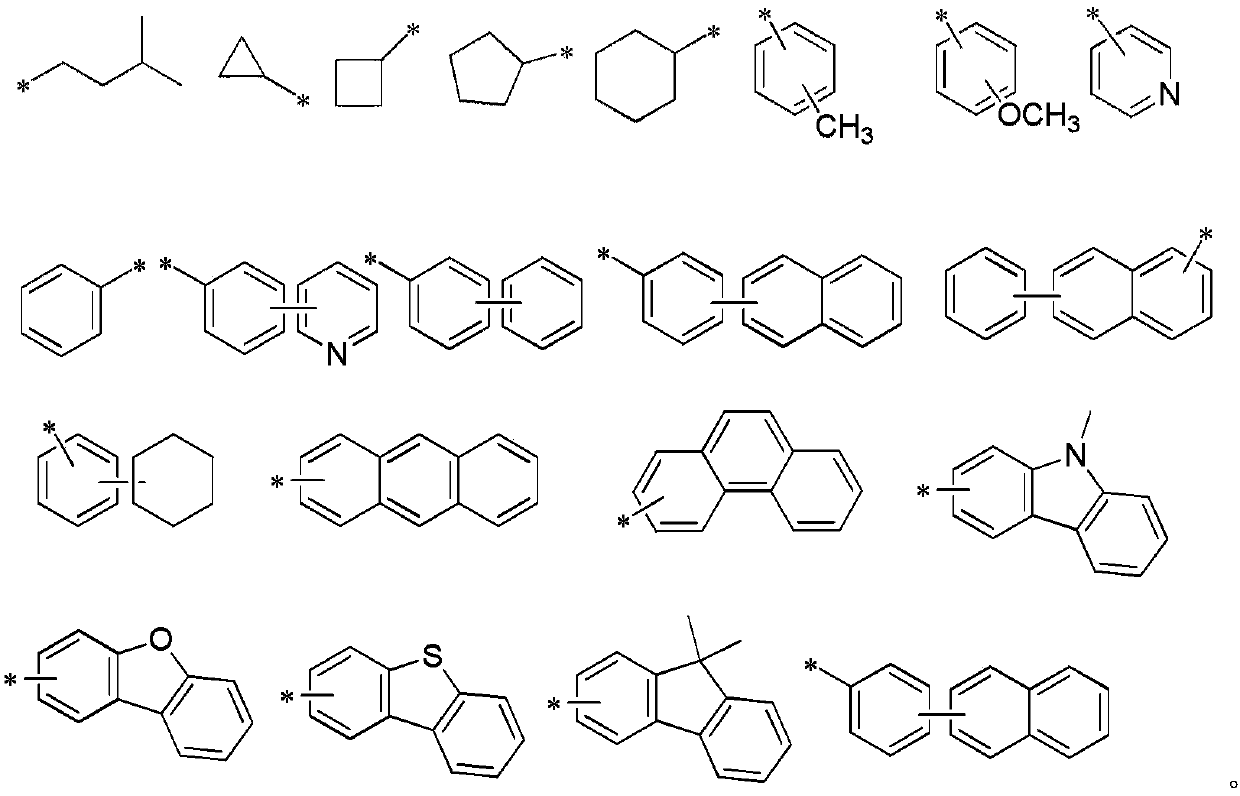

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Preparation of intermediate M1:

[0055] Under the protection of nitrogen, add 400ml pivalic acid to a 1000ml single-necked flask and heat it to 50℃. Add bis(4-isopropyl)aniline (40g, 0.158mol), palladium acetate (35.6g, 0.158mol), carbonic acid at 50℃. Potassium (21.8g, 0.158mol), warm up to 100 degrees Celsius and react overnight. After the reaction is complete, extract with dichloromethane. Add 1000ml of saturated potassium carbonate to dichloromethane and stir well for 3 hours. After separation, filter with suction and reuse the organic phase. Wash once with 2000ml of saturated brine, spin dry, pass the silica gel through the column, spin dry the eluent, boil and wash with a small amount of petroleum ether to obtain 16g, the product, the yield is 40%, the purity is 99.9%, and it is off-white solid.

[0056] Preparation of compound C1:

[0057] Under the protection of nitrogen, add 3.1 g of sodium hydride to a 1000 ml three-necked flask, dissolve it in 50 ml of DMF, add 24...

Embodiment 1z

[0081] The obtained compounds are all prepared by sublimation purification process before device preparation, and the purification equipment is the company's EMT-50-X grade purification equipment. The specific operation process is as follows:

[0082] Take 1g of compound C7 and place it in a quartz boat, place the quartz boat in the purification equipment, and apply a vacuum to the equipment. When the vacuum degree is stable between 10-2~10-3Pa, set three temperature zones at 100℃ to turn on heating;

[0083] Gradually increase the temperature control, maintain an appropriate temperature difference between the high temperature zone, the medium temperature zone and the low temperature zone, observe the sublimation phenomenon, stop heating when a small amount of film is produced, and keep the temperature until the material sublimation is completed;

[0084] Open the furnace cover and wait for the temperature to drop to room temperature, turn off the pump, turn on the nitrogen, balance ...

Embodiment 1

[0114] The preparation process of organic electroluminescent device is as follows:

[0115] The glass plate coated with the transparent conductive layer of ITO is ultrasonically treated in a commercial cleaning agent, rinsed in deionized water, degreasing ultrasonically in a mixed solvent of acetone and ethanol, and baked in a clean environment until the water is completely removed. Light and ozone cleaning, and bombard the surface with low-energy cation beams;

[0116] Put the above-mentioned glass substrate with anode in the vacuum chamber and evacuate to 1×10 -5 ~9×10 -3 Pa, HI-2 was vacuum-evaporated on the above-mentioned anode layer film as a hole injection layer, the evaporation rate was 0.1 nm / s, and the evaporation film thickness was 10 nm;

[0117] Vacuum evaporate HT-2 on the hole injection layer as the hole transport layer of the device, the evaporation rate is 0.1nm / s, and the total evaporation film thickness is 40nm;

[0118] Vacuum evaporate HT-28 on the hole transport ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com