Release agent for reactive hot melt resin

A reactive, stripping agent technology, applied in the direction of adhesives, adhesive types, heat-activated films/sheets, etc., can solve the problems of substrates that cannot be reworked and peeled off, and achieve excellent reworkability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

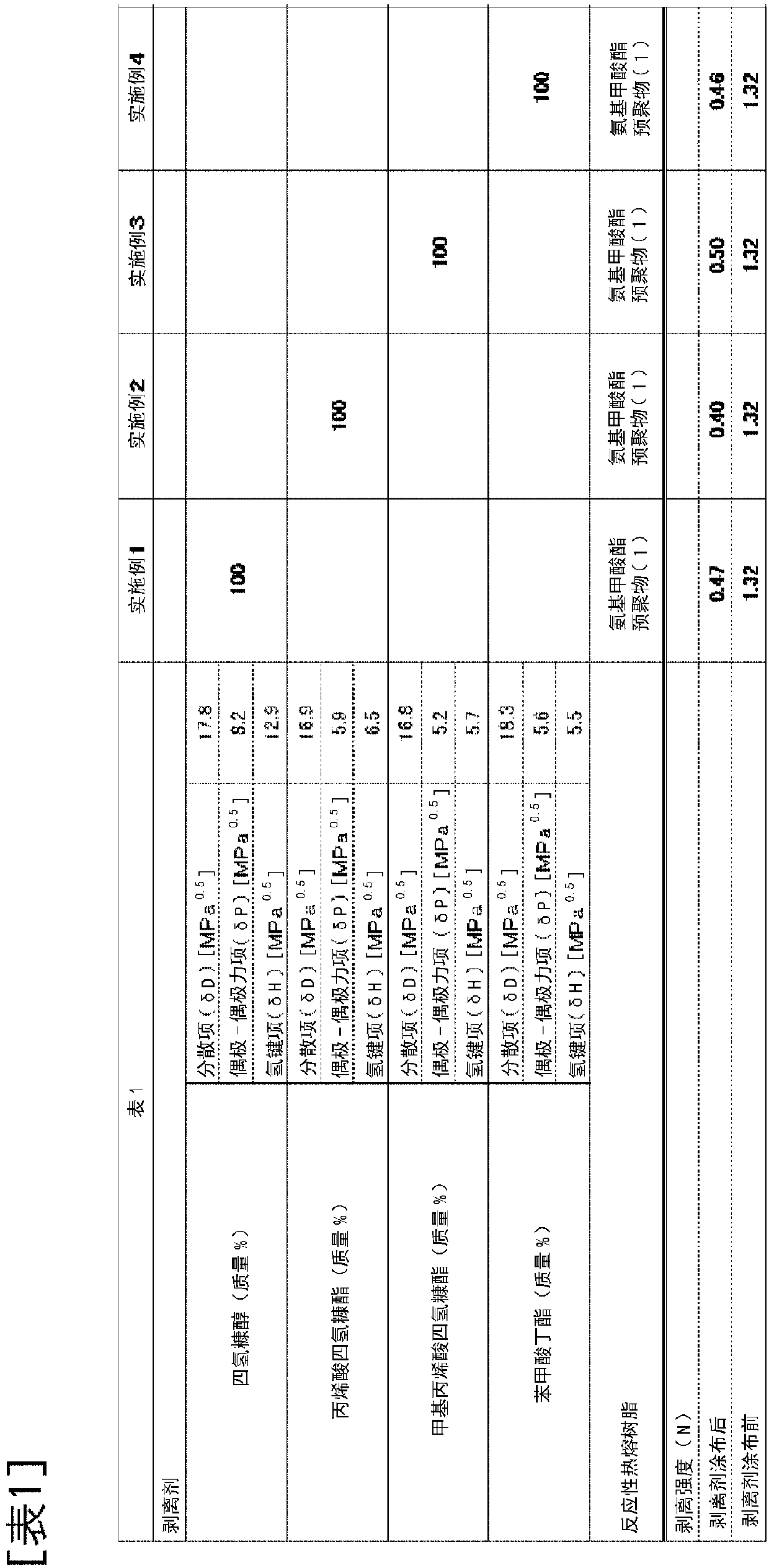

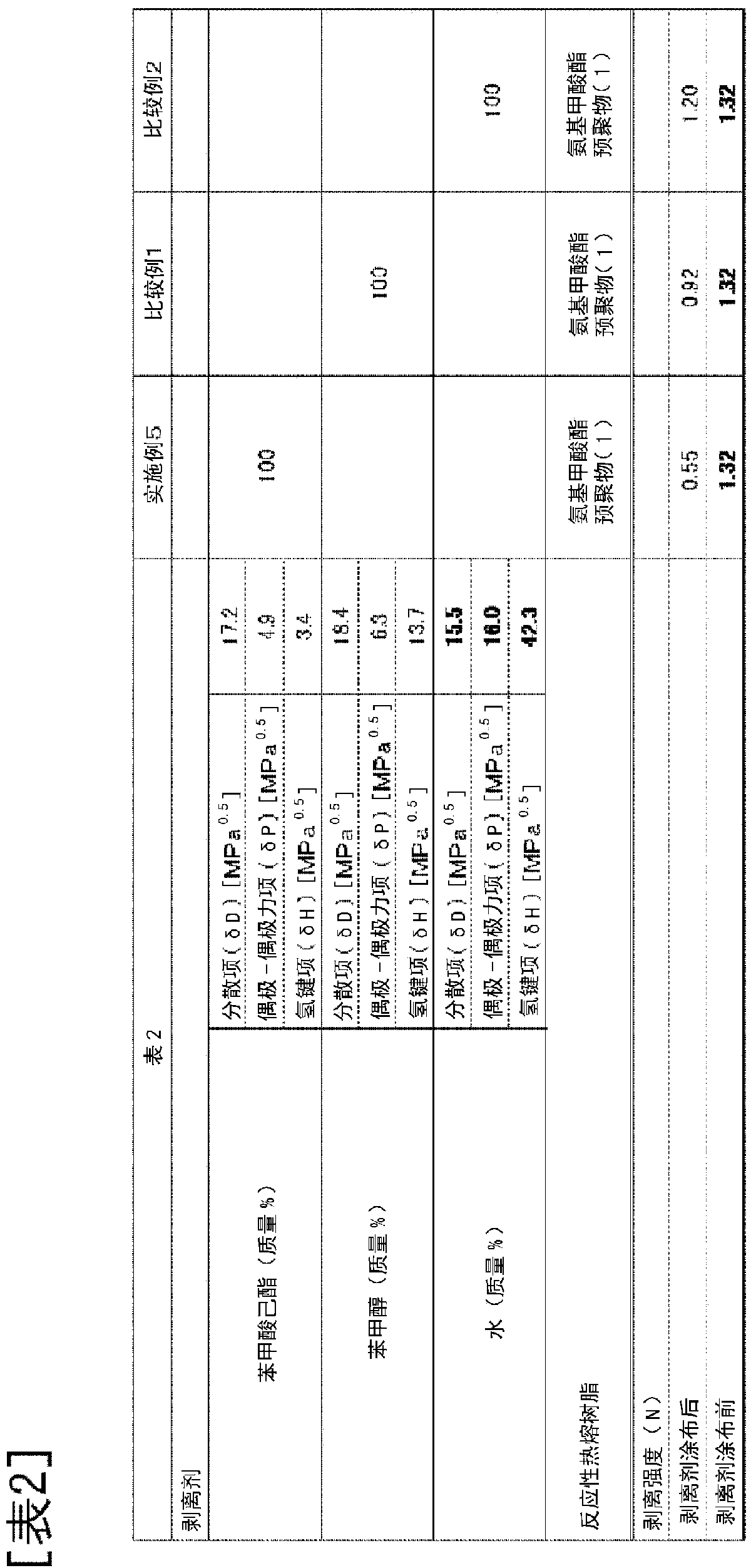

[0048] Hereinafter, the present invention will be described in more detail using examples.

Synthetic example 1

[0050]

[0051] In a four-necked flask equipped with a thermometer, a stirrer, an inert gas inlet, and a reflux cooler, add 15 parts by mass of polypropylene glycol (number average molecular weight: 1000), 15 parts by mass of polypropylene glycol (number average molecular weight: 2000), 10 parts by mass of crystalline polyester polyol (made by reacting 1,6-hexanediol with adipic acid, number average molecular weight: 2000), 10 parts by mass of crystalline polyester polyol (made by making 1,6- Hexylene glycol reacted with 1,12-dodecanedicarboxylic acid, number average molecular weight: 3500), 15 parts by mass of amorphous polyester polyol (6 moles of propylene oxide adduct of bisphenol A , sebacic acid and isophthalic acid, the number average molecular weight: 2000), 2.5 parts by mass of acrylic polyol (making butyl acrylate / methyl methacrylate / ethyl acrylate / 2-hydroxyethyl methacrylate Ester = 69.65 / 25 / 5 / 0.35 (mass ratio), number average molecular weight: 13000, glass transi...

Embodiment 1

[0084] On the PET film / adhesive layer of the obtained laminate, apply a release agent of 100% by mass tetrahydrofurfuryl alcohol using a cotton swab, leave it for 5 minutes in a temperature environment of 23°C, peel off the straight tip with tweezers, and then fix it A peelability test was performed by measuring the peel strength (N) with a popular digital force gauge ("DS2-200N" manufactured by Imada Corporation). In addition, the peelability test of the laminated body before applying a release agent was also performed together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com