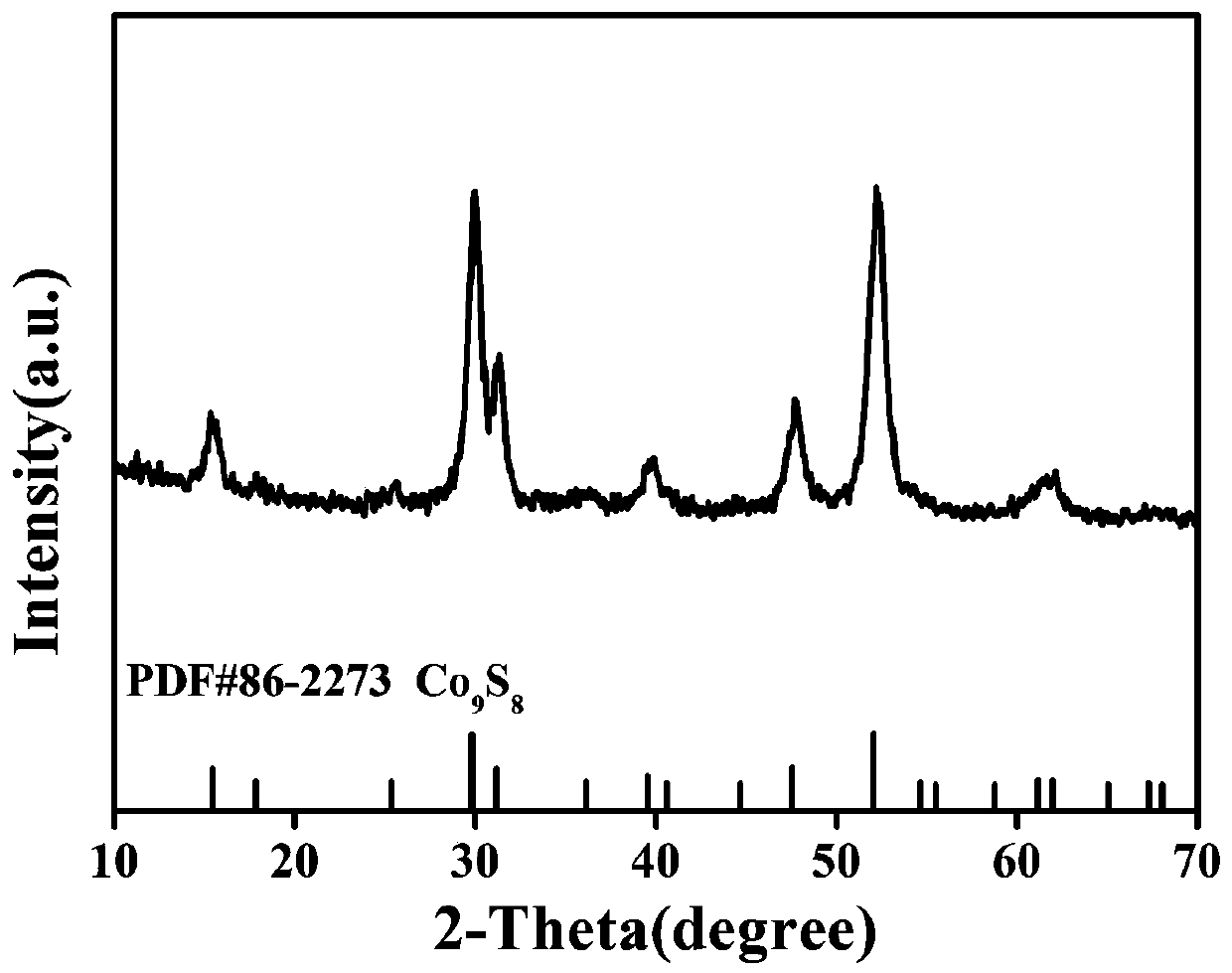

Arachnoid cobalt sulfide powder and preparation method thereof

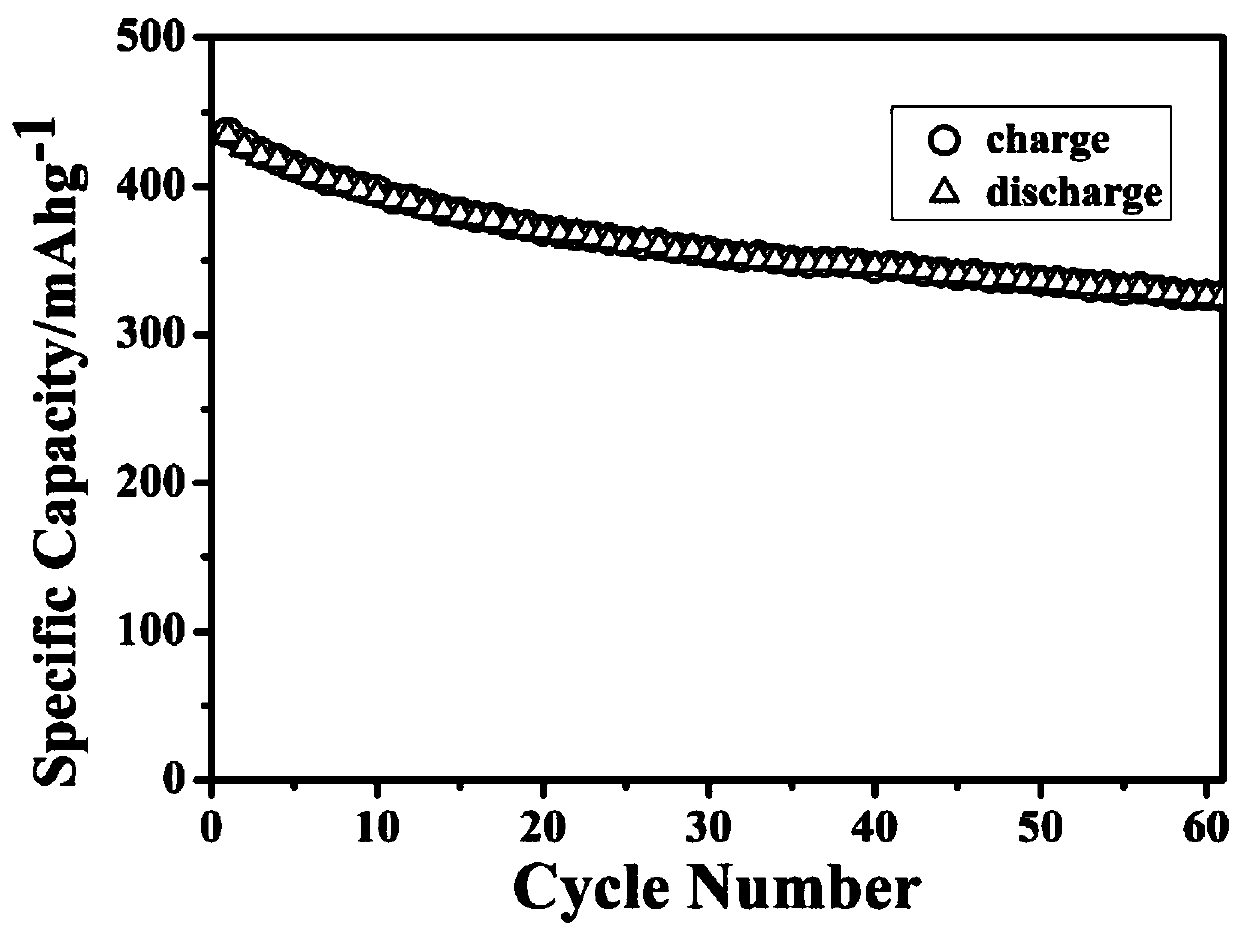

A technology of cobalt sulfide and cobwebs, which is applied in cobalt sulfide, chemical instruments and methods, inorganic chemistry, etc., to achieve the effect of simple synthesis path, stable stability and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of cobweb-like Co of the present invention 9 S 8 The preparation method of powder comprises the following steps:

[0026] Step 1, dissolve cobalt acetate tetrahydrate in ethanol, and uniformly prepare solution A by magnetic stirring, and Co in solution A 2+ The concentration is 0.08~0.15mol / L; dissolve thioacetamide in an equivalent amount of ethanol, and obtain solution B by magnetic stirring; wherein, the molar ratio of cobalt acetate tetrahydrate to thioacetamide is 1: (0.8-1.5), The speed of magnetic stirring is 700~750r / min, and the time is 15~30min

[0027] Step 2, pour solution B into solution A, and obtain solution C by stirring evenly, at this time, solution C is a pink clear solution;

[0028] Step 3: Pour the solution C into a polytetrafluoroethylene-lined reaction kettle with a filling degree of 40% to 60%, and in a homogeneous reactor with a rotation speed of 10 to 15r / min at a uniform speed, from room temperature to Heating to 150-170°C for solv...

Embodiment 1

[0032] A kind of cobweb-like Co of the present invention 9 S 8 The preparation method of powder comprises the following steps:

[0033] Step 1, dissolve cobalt acetate tetrahydrate in ethanol, stir magnetically for 15min at a speed of 700r / min, and prepare Co 2+ For solution A with a concentration of 0.08mol / L, the molar ratio of cobalt acetate tetrahydrate to thioacetamide is 1:0.8, and thioacetamide is dissolved in the same amount of ethanol as the first time, at a speed of 700r / min , magnetically stirred for 15 minutes to obtain solution B;

[0034] Step 2, pour solution B into solution A, and obtain a clear pink solution C by stirring evenly;

[0035] Step 3, according to the filling ratio of 40%, pour the mixed solution into the reaction liner and seal it, install the liner in the outer kettle and fix it, place it in a homogeneous reactor, and heat it from room temperature to 150 °C at 10 r / min. ℃ for solvothermal reaction 20h;

[0036] Step 4, after the solvothermal...

Embodiment 2

[0041] A kind of cobweb-like Co of the present invention 9 S 8 The preparation method of powder comprises the following steps:

[0042] Step 1, dissolve cobalt acetate tetrahydrate in ethanol, stir magnetically for 20min at a speed of 720r / min, and prepare Co 2+For solution A with a concentration of 0.12mol / L, the molar ratio of cobalt acetate tetrahydrate to thioacetamide is 1:1, and thioacetamide is dissolved in the same amount of ethanol as the first time, at a speed of 720r / min , magnetically stirred for 20min to obtain solution B;

[0043] Step 2, pour solution B into solution A, and obtain a clear pink solution C by stirring evenly;

[0044] Step 3, according to the filling ratio of 50%, pour the mixed solution into the reaction liner and seal it, install the liner in the outer kettle and fix it, place it in a homogeneous reactor, and heat it from room temperature to 170 °C under the condition of 12 r / min speed. ℃ for solvothermal reaction for 23h;

[0045] Step 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com