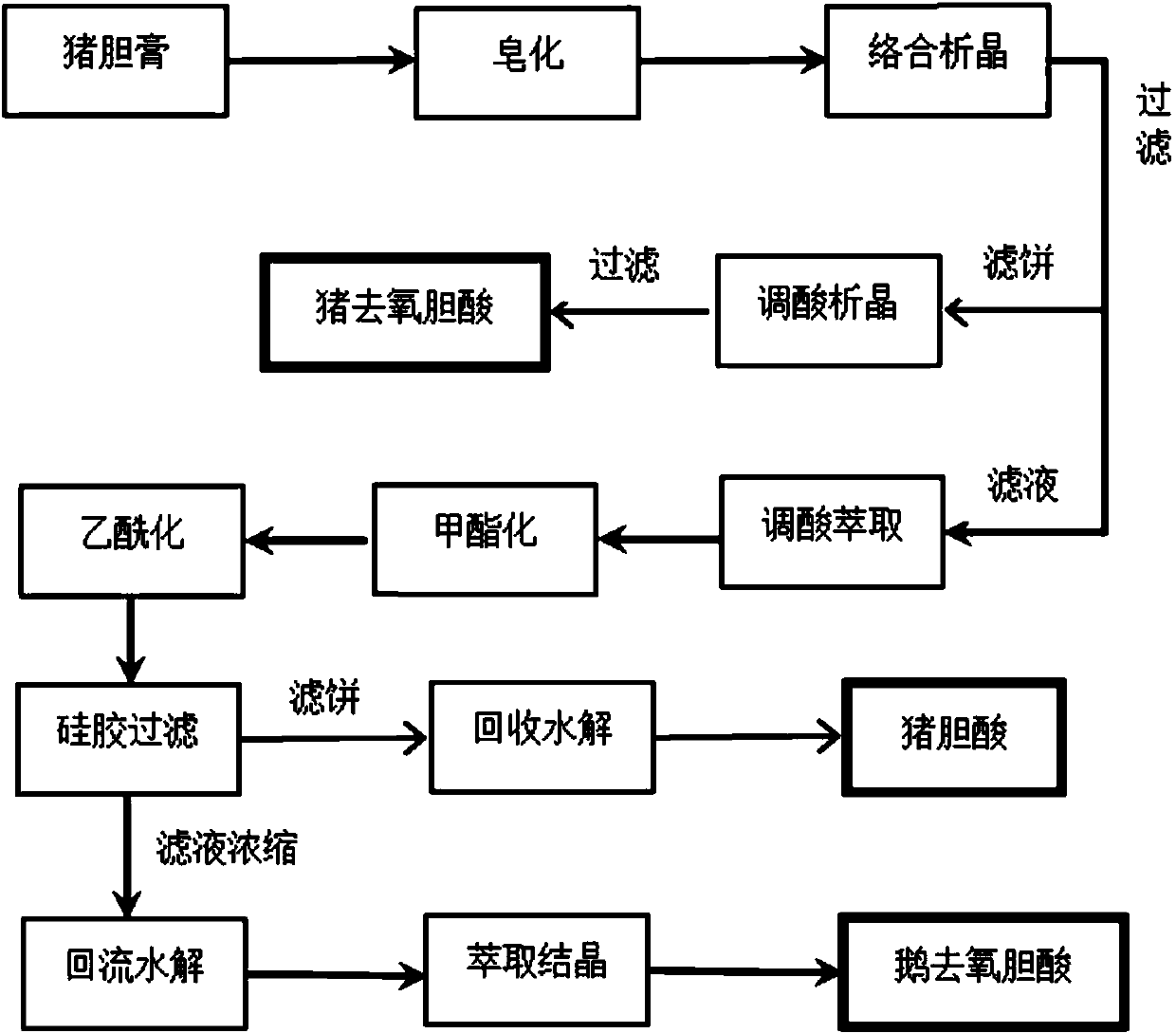

Method for extracting chenodeoxycholic acid from pig gall paste

A technology of chenodeoxycholic acid and pig gall paste, which is applied in the fields of steroids and organic chemistry, can solve the problems of low extraction yield, difficult separation, waste of water resources, etc., and achieve improved extraction yield and good separation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

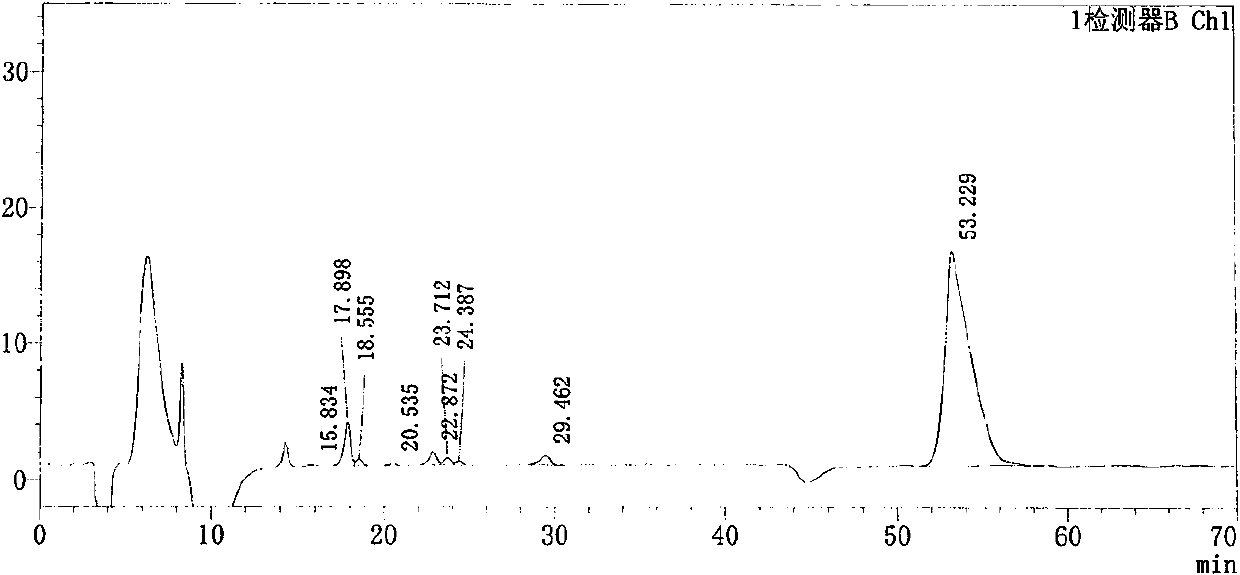

[0060] A method for extracting chenodeoxycholic acid from pig bile paste, which is an embodiment of a laboratory test, has included the following steps:

[0061] (1) Saponification: take 3 kg of pig gall paste (HPLC content 22.1%), the pig gall paste is dark brown and is a blocky solid. Put it into a 30L reaction kettle, add 9 kg of water and 1.2 kg of sodium hydroxide, heat to reflux at 100°C for saponification, and the duration of saponification is 12 hours.

[0062] (2) Complexation crystallization: reflux the saponified reaction solution for 8 hours and cool it to 48°C, add hydrochloric acid to adjust the pH to 10, then add magnesium chloride aqueous solution (1.5 kg magnesium chloride hexahydrate dissolved in 3.3 kg water), and stir at 50°C After 4 hours, filter and rinse with 0.6 kg of water to obtain filtrate and filter cake. The filter cake is hyodeoxycholic acid magnesium salt, and the filtered hyodeoxycholic acid magnesium salt is added with water and acid to dissoc...

Embodiment 2

[0082] A method for extracting chenodeoxycholic acid from pig bile paste, which is the second embodiment of the laboratory test, has included the following steps:

[0083] (1) Saponification: take 3 kg of pig gall paste (HPLC content 22.1%), the pig gall paste is dark brown and is a blocky solid. Put it into a 30L reaction kettle, add 9 kg of water and 1.2 kg of sodium hydroxide, heat to reflux at 100°C for saponification, and the duration of saponification is 12 hours.

[0084] (2) Complexation and crystallization: reflux the saponified reaction solution for 8 hours and cool it to 40°C, add hydrochloric acid to adjust the pH to 11, then add magnesium chloride aqueous solution (1.8 kg of magnesium sulfate heptahydrate dissolved in 3.3 kg of water), 35°C Stir for 4 hours, then filter and rinse with 0.6 kg of water to obtain filtrate and filter cake. The filter cake is hyodeoxycholic acid magnesium salt, and the filtered hyodeoxycholic acid magnesium salt is added with water an...

Embodiment 3

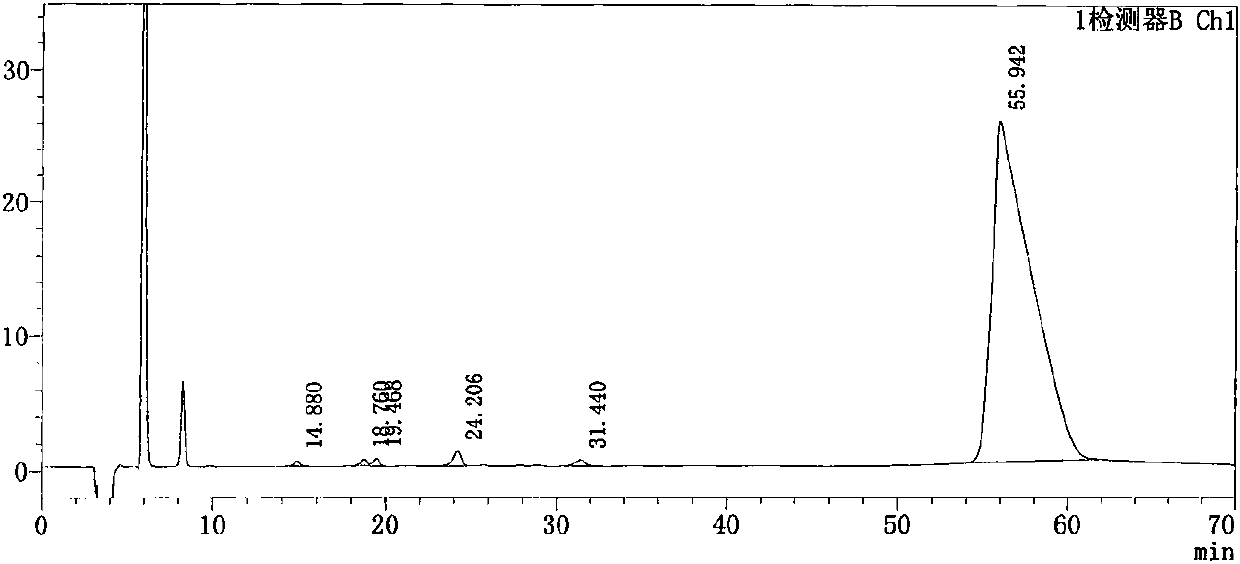

[0096] A method for extracting chenodeoxycholic acid from pig bile paste, which is an embodiment of a pilot test in a factory, has included the following steps:

[0097] (1) Saponification: take 90 kg of pig gall paste (HPLC content 22.1%), the pig gall paste is dark brown and is a blocky solid. Put it into a 1000L reactor, add 270 kg of water and 36 kg of sodium hydroxide, heat to reflux at 98°C for saponification, and the duration of saponification is 12 hours.

[0098] (2) Complexation and crystallization: reflux the saponified reaction solution for 8 hours and cool it to 44°C, add hydrochloric acid to adjust the pH to 9, then add magnesium chloride aqueous solution (45 kg magnesium chloride hexahydrate dissolved in 100 kg water), at 42°C Stir for 4 hours, then filter and rinse with 18 kg of water to obtain filtrate and filter cake. The filter cake is hyodeoxycholic acid magnesium salt, and the filtered hyodeoxycholic acid magnesium salt is added with water and acid to dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com