A kind of gas well foam discharge agent composition, preparation method and application thereof

A foam discharge agent and composition technology, applied in the field of gas well foam discharge agent composition, can solve the problems of gas well production reduction, excessive fluid accumulation, stop spraying, etc., and achieve the effects of increasing viscosity, improving salt resistance, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] A method for preparing a foam discharge agent composition for gas recovery from temperature-resistant and salt-resistant drainage, comprising the following steps:

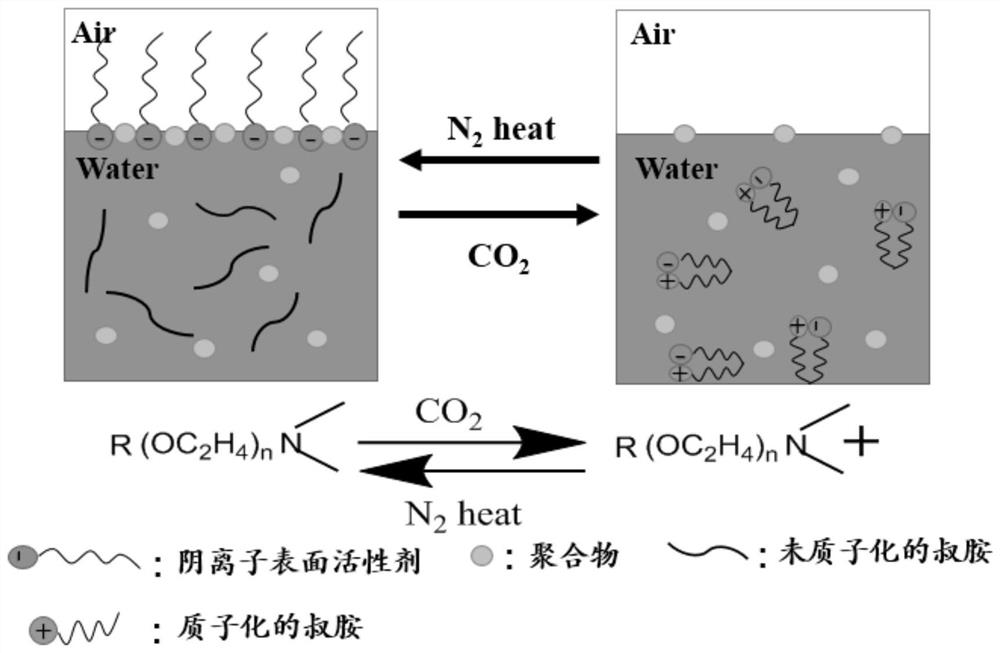

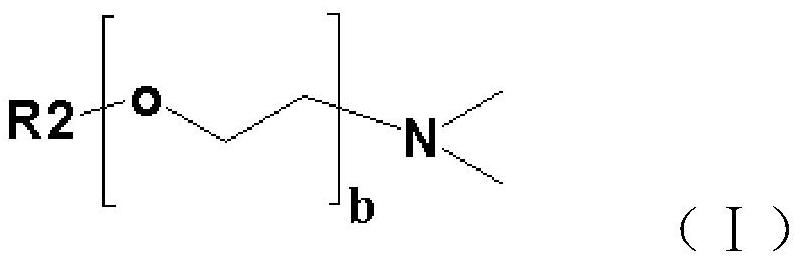

[0064] (1)CO 2 / N 2 Synthesis of Switch Salt Tolerance Responsive Tertiary Amines

[0065] a. Add R to the three-necked flask 3 -Br and H(OCH 2 CH 2 ) b OH, in N 2 React under protection, obtain alkyl polyoxyethylene ether base alcohol intermediate;

[0066] b. Mix the alkyl polyoxyethylene ether-based alcohol intermediate and the sulfonating agent in a molar ratio of 3: (1-2), and then react with dimethylamine in a hydrothermal reactor at a reaction temperature of 150 React at ~180°C for 7-9 hours to obtain the target product, alkylpolyoxyethylene ether-based tertiary amine, and the sulfonating reagent is halogenated sulfonic acid and its salt.

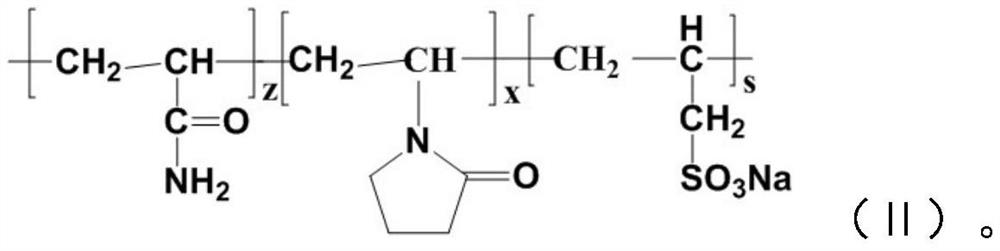

[0067] (2) Synthesis of polymer AM-NVP-AS

[0068] The synthesis of the polymer adopts the method of free radical polymerization, and the raw materials ar...

Embodiment 1

[0075] The preparation of composition 1, preparation steps:

[0076] (1) Synthesis of salt-tolerant responsive tertiary amines

[0077] a. Add 13gC to the three-necked flask 12 h 25 Br and 22g diethylene glycol react to obtain the alkyl polyoxyethylene ether alcohol intermediate;

[0078] b. React 12g of alkyl polyoxyethylene ether-based alcohol intermediate, sulfonating reagent and 35g of dimethylamine aqueous solution in a hydrothermal reaction kettle, and react at a reaction temperature of about 165°C for 8 hours to obtain the target product 12 Alkyl polyoxyethylene ether-based tertiary amine, the sulfonating agent is halogenated sulfonic acid and its salt.

[0079] (2) Preparation of foam discharge agent composition

[0080] Dissolve lauryl polyoxyethylene ether-based tertiary amine, anionic surfactant, and self-synthesized polymer AM-NVP-AS in a mineralization degree of 50,000 mg / L and a pH of 7 according to a mass ratio of 1:1:1. In the mixture of ethanol and water,...

Embodiment 2

[0082] The preparation of composition 2, preparation steps:

[0083] (1) Synthesis of salt-tolerant responsive tertiary amines

[0084] a. Add 10gC to the three-necked flask 10 h 21 Br and 22g diethylene glycol react to obtain the alkyl polyoxyethylene ether alcohol intermediate;

[0085] b. React 12g of alkyl polyoxyethylene ether-based alcohol intermediate, sulfonating reagent and 38g of dimethylamine aqueous solution in a hydrothermal reaction kettle, and react at a reaction temperature of about 165°C for 7.5 hours to obtain the target product 12 Alkyl polyoxyethylene ether-based tertiary amine, the sulfonating agent is halogenated sulfonic acid and its salt.

[0086] (2) Preparation of foam discharge agent composition

[0087] Dissolve dedecyl polyoxyethylene ether-based tertiary amine, anionic surfactant, and self-synthesized polymer AM-NVP-AS in ethanol with a salinity of 80,000 mg / L and a pH of 7 according to a mass ratio of 2:1:1 In the mixed solution with water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com