Nano-silver synthetic protein derived from lysinibacillus sphaericus and application of nano-silver synthetic protein

A technology of bacillus and nano-silver, which is applied in the field of protein purification technology and genetic engineering, and can solve problems such as environmental or biological hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of sample strain fermentation supernatant. Take out the sample strain (Lysinibacillus sphaericus) and put it into the ice box to slowly thaw, inoculate 2% of the inoculation amount into a 250mL Erlenmeyer flask containing 100mL liquid seed medium, and culture it on a shaker at 37°C and 200rpm for 24h. Then inoculate the above seed liquid into the fermentation medium according to the inoculum amount of 2%. After fermenting on a shaker at 37° C. and 200 rpm for 48 hours, measure the pH of the fermentation broth. Use a desktop high-speed refrigerated centrifuge to centrifuge at room temperature and 10,000 rpm for 10 minutes, and collect the supernatant of the fermentation broth.

Embodiment 2

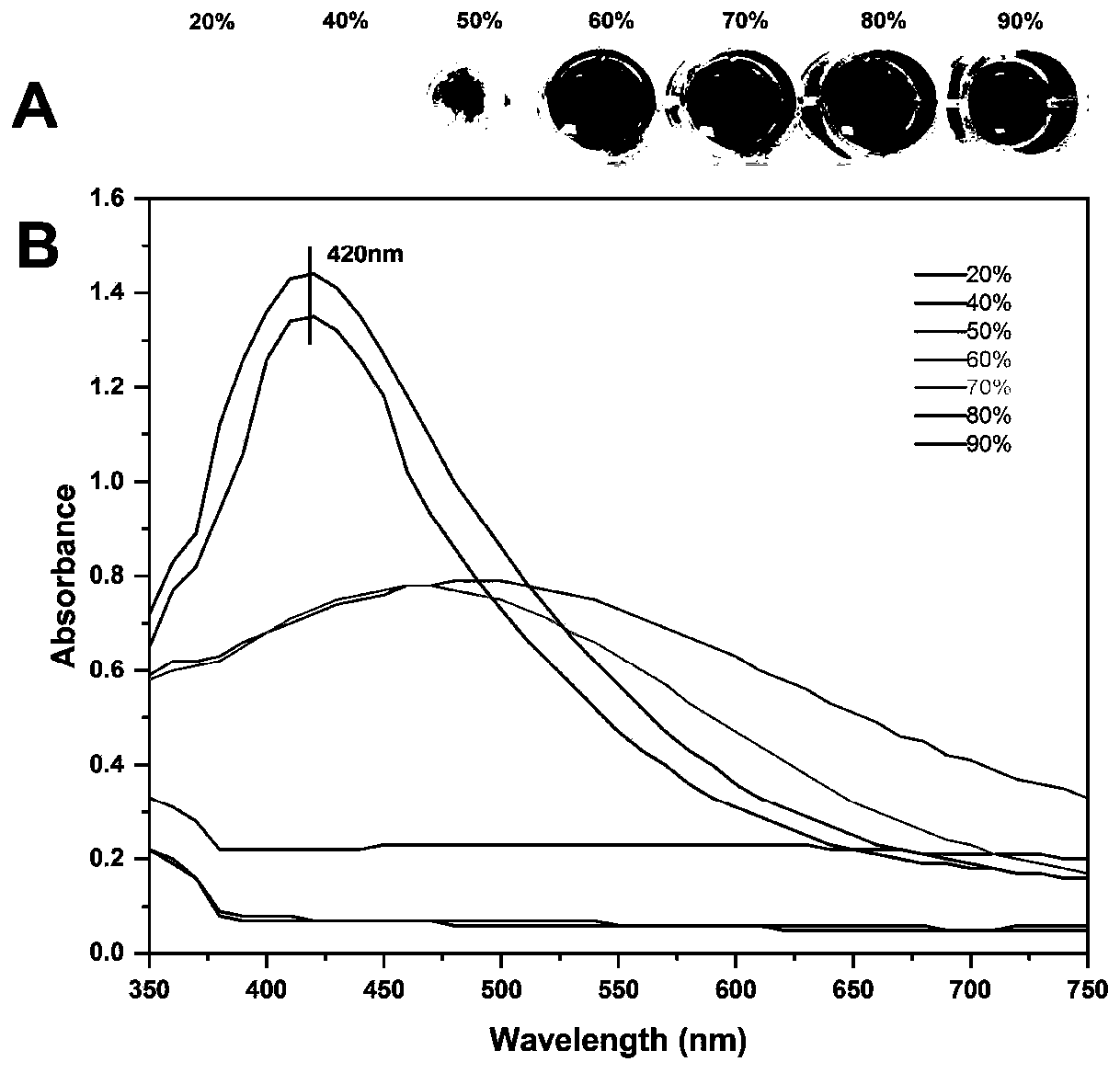

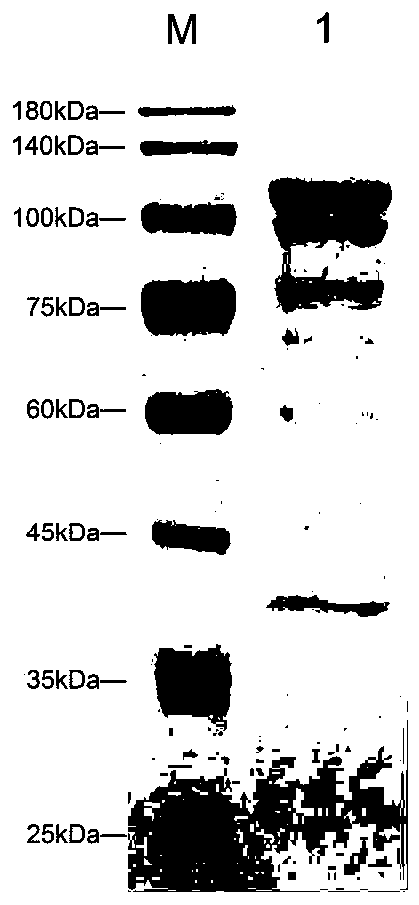

[0032] Using the ammonium sulfate fractional precipitation method, the supernatant protein of the fermentation broth was preliminarily purified. Make 7 groups (20%, 40%, 50%, 60%, 70%, 80%, 90%) saturation, each group 100mL fermentation supernatant. Slowly add a corresponding amount of ammonium sulfate solid to each reaction system according to the calculation table for adjusting the saturation of the ammonium sulfate solution. Stir overnight on a magnetic stirrer at 4°C to fully precipitate the protein. The resulting solution was centrifuged at 10,000×g for 30 min, and the supernatant and precipitate were kept in groups. Dissolve the precipitated protein obtained by salting out at various saturations in a small amount (about 10ml) of ultrapure water, put the precipitate into a dialysis bag to dialyze the pure water system for 24 to 48 hours, and change the dialysis buffer every 3 to 6 hours Once (use a dropper or pipette gun to pipette a small amount of solution with BaCl ...

Embodiment 3

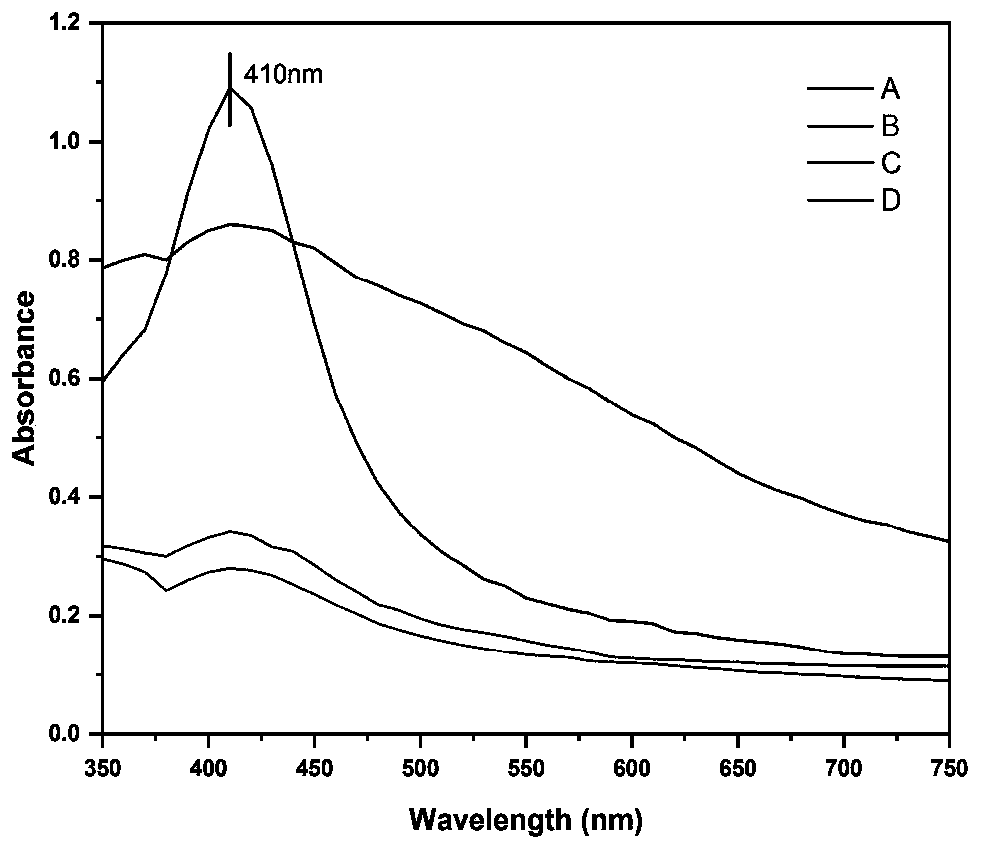

[0034] The synthesis ability of nano-silver was measured for the dialyzed protein solution at various saturation levels. Through continuous exploration and experimentation, changing the concentration of silver nitrate substrate, temperature, pH and other influencing factors, optimizing the synthesis conditions, the final reaction conditions were determined to be: 5mL dialyzed protein solution (concentration of about 50ug / mL, pH 9.0-12.0)+AgNO 3 (Substrate concentration 15-20mM) Reaction (water-bath shaker 35-45°C, rotational speed 150-200r) for 24h.

[0035] Prepare 7 test tubes, adjust the concentration of 7 groups of dialyzed protein solutions at different saturations to about 50ug / mL in 5ml systems, react according to the above reaction conditions for 24h, and then take the upper liquid. Dilute the appropriate multiple according to the state (20 and 40 saturations do not need to be diluted, 50 and 60 saturations are diluted 10 times, 70 and 80 saturations are diluted 50 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com