Dielectric material with high dielectric constant, preparation method therefor and application of dielectric material

A technology of high dielectric constant and dielectric material, applied in fixed capacitor parts, circuits, capacitors, etc., can solve problems such as the influence of metal film adhesion, achieve good performance, improved dielectric constant, high dielectric The effect of electric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

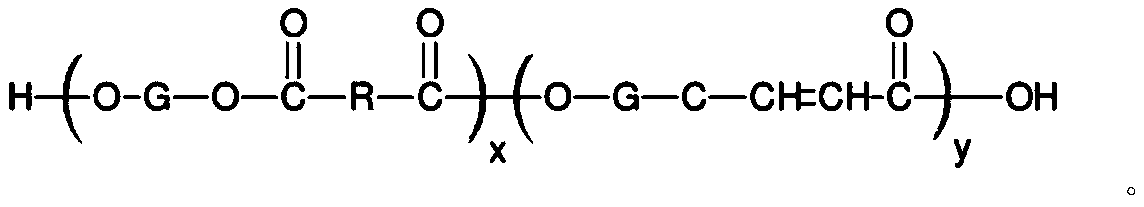

[0022] In one aspect of the present invention, a kind of preparation method of the dielectric material with high dielectric constant is provided, and this preparation method comprises the steps:

[0023] First, the thermosetting resin prepolymer, thermoplastic polymer and curing agent are dissolved in a solvent to form a transparent or translucent organic polymer solution; based on the total weight of the organic polymer solution, the thermosetting resin prepolymer accounts for 20-50wt%, such as 20wt%, 25wt%, 30wt%, 35wt%, 40wt%, 45wt% and 50wt%, the thermoplastic polymer accounts for 5-25wt%, such as 5wt%, 10wt%, 15wt%, 20wt% % and 25wt%, the solvent accounts for 20-40wt%, such as 20wt%, 25wt%, 30wt%, 35wt% and 40wt%, and the curing agent accounts for 5-30wt%, such as 5wt%, 10wt%, 15wt% , 20wt%, 25wt% and 30wt%.

[0024] The solvent can simultaneously dissolve the thermosetting resin prepolymer and the thermoplastic polymer, and is selected from one or more of the following ...

Embodiment 1

[0053] First, based on the total weight of the polymer solution to be formed, 45wt% of thermosetting resin prepolymer—epoxy resin CYD128 produced by Sinopec Baling Petrochemical, 5wt% of diethylenetriamine curing agent, 20wt% of The thermoplastic polyetherimide GE2122 was dissolved in 30%wt DMF solvent to form a translucent polyetherimide / epoxy polymer solution.

[0054] Then, add polyetheramine D2300 and barium titanate to the polymer solution of polyetherimide / epoxy resin obtained above, and use a dispersion device to uniformly disperse barium titanate in the polyetherimide / epoxy resin. In the polymer solution, a uniform binary polymer-based dispersion solution is formed; in the binary polymer-based dispersion solution, based on the total weight of the binary polymer-based dispersion solution, polyetherimide / ring The content of the oxygen resin solution is 46.5 wt%, the content of barium titanate is 53.0 wt%, and the content of polyetheramine D2300 is 0.5 wt%. The dispersin...

Embodiment 2

[0058] The preparation process of the flexible film capacitor of Example 2 is similar to that of Example 1, the difference is that: the thermosetting resin prepolymer is Olester Q850 hydroxyacrylic acid produced by Mitsui Chemicals, and the curing agent is JX-620 produced by Jiangxing Industrial Co., Ltd. The blocked isocyanate curing agent system, the thermoplastic polymer adopts the brand of 1180A10 polyurethane resin produced by BASF; based on the total weight of the binary polymer-based dispersion solution, the content of hydroxyl acrylic acid is 45wt%, and the content of the blocked isocyanate curing agent system is 5wt %, the content of polyurethane resin is 15wt%, and the content of DMF solvent is 35%wt.

[0059] In this embodiment, the average thickness of the dielectric material layer of the obtained flexible film capacitor is 6 μm, and the average dielectric constant is 28.9. Using 180°peel test to test the bonding force between the dielectric material and the copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com