Graphene engine oil antiwear agent and preparation method thereof

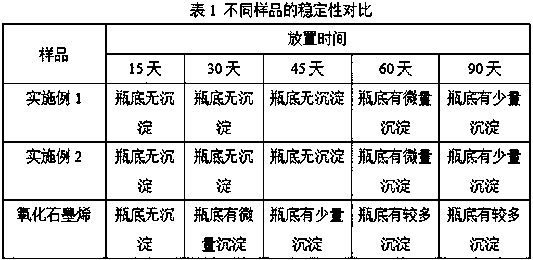

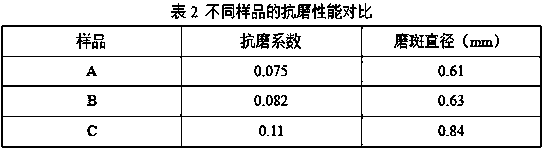

A technology of olefinic motor oil and anti-wear agent, which is applied in the field of lubricating oil, can solve the problems of easy aggregation and precipitation, difficulty in uniform dispersion, etc., and achieve the effects of improving dispersion performance, preventing precipitation, and enhancing anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Embodiments of the present invention provide a graphene engine oil antiwear agent and a preparation method thereof, comprising the following steps:

[0025] (1) Dissolving graphene oxide in toluene and ultrasonically dispersing to form a graphene oxide dispersion;

[0026] (2) Dissolving sodium azide and cyanuric chloride in toluene to form a reaction solution;

[0027] (3) Add the reaction solution to the graphene oxide dispersion, and perform secondary ultrasonic dispersion to form a mixed solution;

[0028] (4) Add the mixed solution into the reaction kettle for solvothermal reaction to prepare carbon nitride-modified graphene composite materials;

[0029] (5) Centrifuge and wash to obtain the graphene engine oil antiwear agent.

[0030] Wherein, the multilayer graphene oxide in the step (1) is prepared by the hummers method, and the number of layers is 10-50. The friction coefficient of graphene with 10-50 layers is smaller than that of single-layer graphene, and...

Embodiment 1

[0037] Embodiment 1 of the present invention provides a graphene engine oil antiwear agent and a preparation method thereof, comprising the following steps:

[0038] (1) Dissolve graphene oxide in 30ml of toluene, ultrasonically disperse at 180w for 40min, and form a graphene oxide dispersion with a concentration of 0.16 mg / mL;

[0039] (2) Dissolve sodium azide and cyanuric chloride in 30ml of toluene to form a reaction liquid, the concentration of sodium azide in the reaction liquid is 45 mg / mL, and the concentration of cyanuric chloride is 40 mg / mL;

[0040] (3) Add the reaction liquid to the graphene oxide dispersion, 180w ultrasonic for 5min, and ultrasonically disperse to form a mixed liquid;

[0041] (4) Add the mixed solution into a 150ml reactor for solvothermal reaction at a reaction temperature of 200°C and a reaction time of 15 hours to prepare a carbon nitride-modified graphene composite material;

[0042] (5) Centrifuge, wash with acetonitrile for 3 times, and f...

Embodiment 2

[0044] Embodiment 2 of the present invention provides a graphene engine oil antiwear agent and a preparation method thereof, comprising the following steps:

[0045] (1) Dissolve graphene oxide in 30ml of toluene, ultrasonically disperse at 180w for 60min, and form a graphene oxide dispersion with a concentration of 0.12 mg / mL;

[0046] (2) Dissolve sodium azide and cyanuric chloride in 30ml of toluene to form a reaction liquid, the concentration of sodium azide in the reaction liquid is 50 mg / mL, and the concentration of cyanuric chloride is 45 mg / mL;

[0047] (3) Add the reaction solution to the graphene oxide dispersion, 180w ultrasonic for 8min, and ultrasonically disperse to form a mixed solution;

[0048] (4) Add the mixed solution into a 150ml reactor for solvothermal reaction at a reaction temperature of 220°C and a reaction time of 12 hours to prepare a carbon nitride-modified graphene composite material;

[0049] (5) Centrifuge, wash 3 times with ether, and finally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com