Flue gas desulfurization system and method using calcium carbide slag/slurry

A desulfurization system, calcium carbide slag technology, applied in separation methods, chemical instruments and methods, calcium/strontium/barium sulfate, etc., can solve the problem that calcium sulfite cannot be effectively dehydrated, sulfur dioxide emissions are not up to standard, and the pH value of tower kettle slurry rises Advanced problems, to avoid environmental risks, ensure absorption, improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

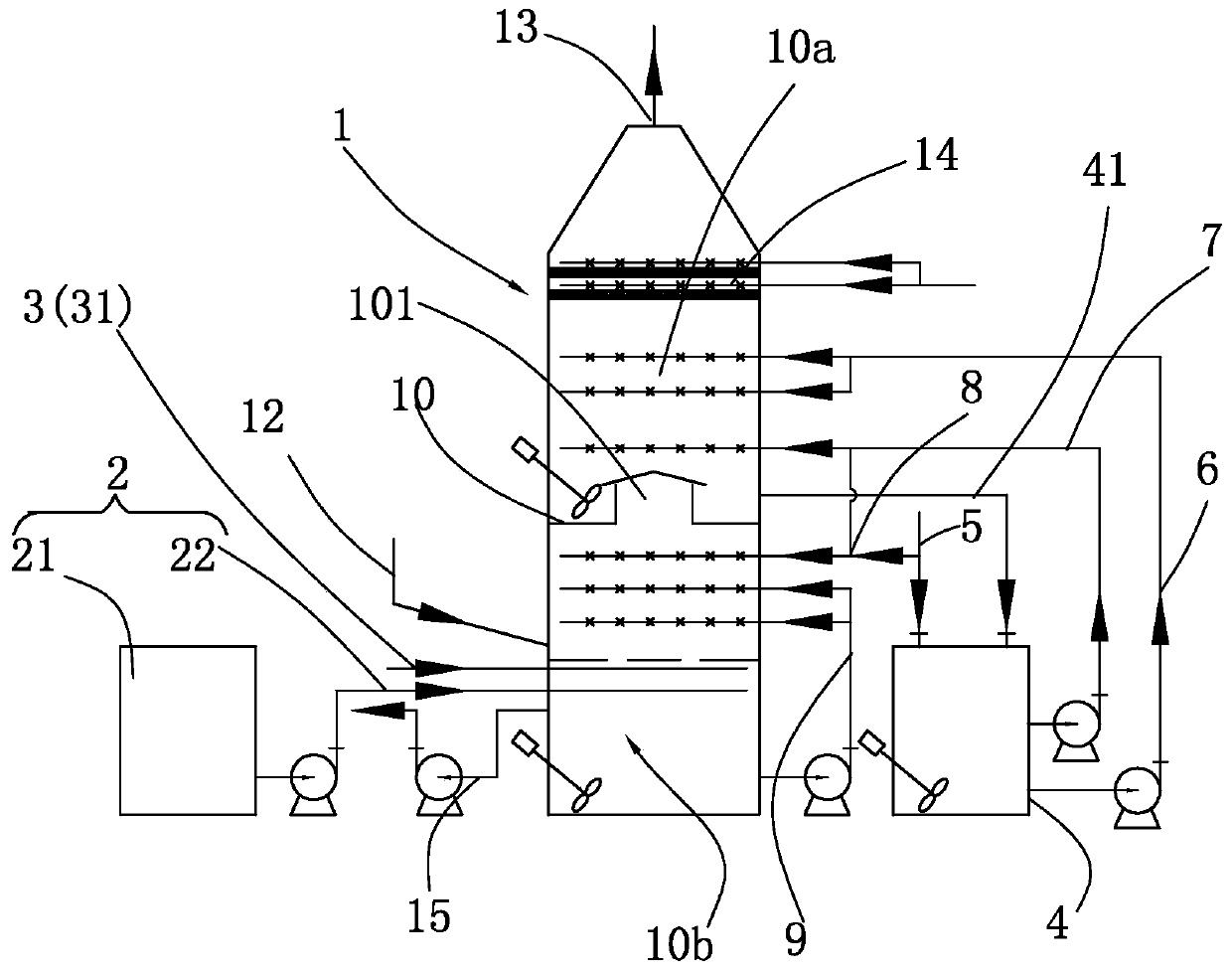

[0044] attached figure 1 It is a schematic diagram of the calcium carbide slag / pulp flue gas desulfurization system provided by the present invention. The calcium carbide slag / slurry flue gas desulfurization system provided by the present invention includes a desulfurization tower 1, a sulfuric acid delivery device 2, an oxidation air delivery device 3, a desulfurization slurry tank 4, a calcium carbide slurry supplementary pipe 5, a first spray device 6, a second spray Showering device 7, third spraying device 8, fourth spraying device 9, partition 10. The partition 10 divides the reaction space in the desulfurization tower into two parts, the sulfur dioxide absorption zone 10a located on the upper part of the partition 10 and the calcium sulfite oxidation zone 10b located on the lower part of the partition 10 .

[0045] The desulfurization tower 1 has a cylindrical structure, with a flue gas pipe 12 at the bottom and an exhaust pipe 13 at the top. The flue gas pipe 12 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com