Preparation method for forming magnetite nanoparticles in cellulose acetate membrane

A cellulose acetate membrane and nanoparticle technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as low flux of CA membrane, increase hydrophilicity, and maintain physical and chemical stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

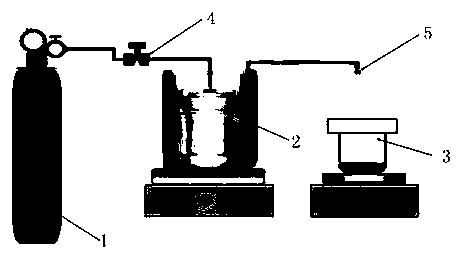

[0034] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0035] The first step is to prepare a cellulose acetate membrane. 8-Hydroxyquinoline and cellulose acetate were dissolved in acetone, and polyvinylpyrrolidone (PVP, MW=25000g / mol) was added as a pore-forming agent, and mechanically stirred for 5 hours to prepare a coating solution. Keep the prepared cellulose solution in acetone in the production environment for a period of time to remove the air bubbles generated by the cellulose solution during the production process.

[0036] The concentrations of polyvinylpyrrolidone and cellulose acetate are selected to be 1-1.5% and 17% respectively.

[0037] In the second step, after adding 8-hydroxyquinoline, use a casting knife to perform solution casting on the glass plate substrate, and place the glass plate in a non-solvent at 18°C to 25°C.

[0038] The concentration of 8-hydroxyquinoline is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com