Method for synthesizing liraglutide

A technology for liraglutide and peptide resin, applied in the field of liraglutide synthesis, can solve the problems of wasting raw materials, increasing costs, affecting downstream purification, etc., so as to reduce the generation of D-Ala, reduce the generation of impurities, and improve the purity and yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

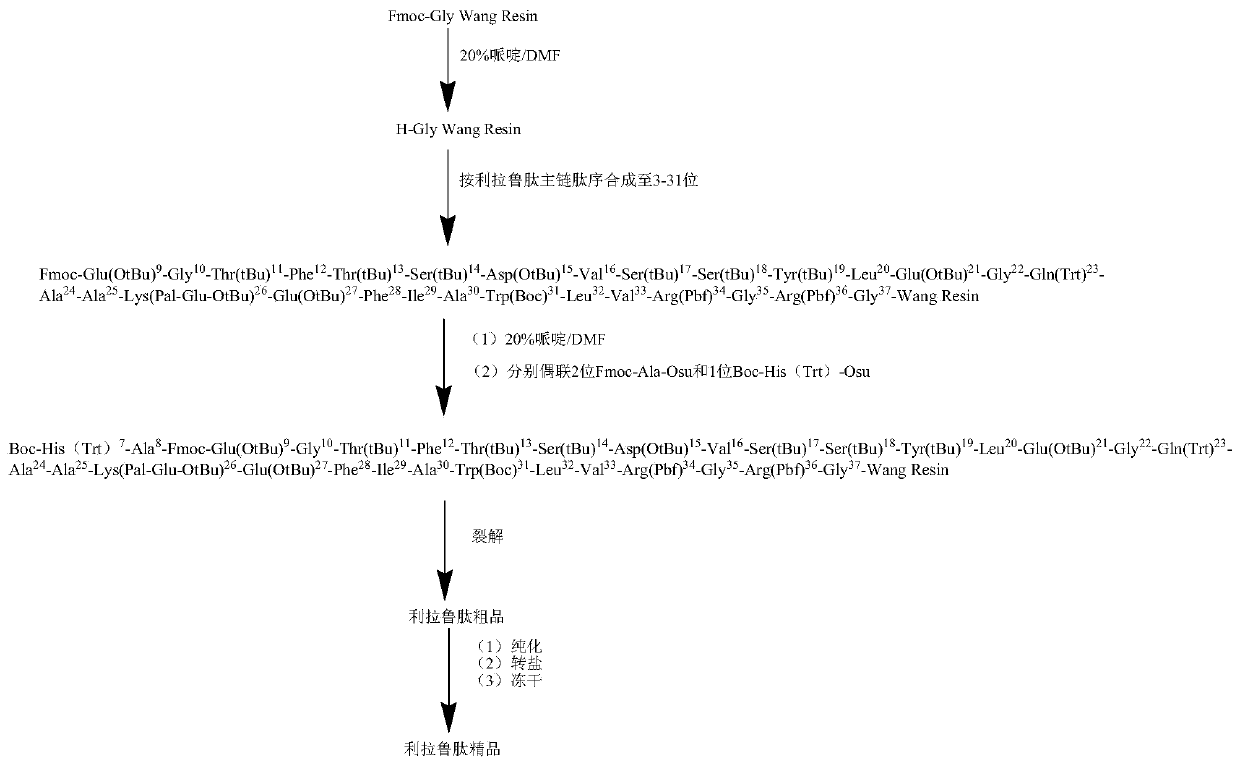

[0038] Example 1: Liraglutide fully protected peptide synthesis

[0039] In this example, liraglutide fully protected peptide refers to: Boc-His (Trt) 7 -Ala 8 -Glu(OtBu) 9 -Gly 10 -T hr(tBu) 11 -Phe 12 -Thr(tBu) 13 -Ser(tBu) 14 -Asp(OtBu) 15 -Val 16 -Ser(tBu) 17 -Ser(tBu) 18 -Tyr(tBu) 19 -Leu 20 -Glu(OtBu) 21 -Gly 22 -Gln(Trt) 23 -Ala 24 -Ala 25 -Lys(Pal-Glu-OtBu) 26 -Glu(OtBu) 27 -Phe 28 -Ile 29 -Ala 30 -Trp(Boc) 31 -Leu 32 -Val 33 -Arg(Pbf)34 -Gly 35 -Arg(Pbf) 36 -Gly 37 -Wang Resin.

[0040] A. Add 100g (30mmol) of Fmoc-Gly-Wang Resin with a substitution degree of 0.3mmol / g into the reaction column, add 400mml of dichloromethane to swell for 30min, and drain it. Add 300ml of 20% piperidine / DMF solution, mix for 5min, then drain, add DMF 300ml, wash for 1min, then drain. Add 300 ml of 20% piperidine / DMF solution, mix for 15 minutes, and drain. Add 300ml of DMF to wash for 1min, then drain and repeat DMF washing 4 times. Take a small amount of...

Embodiment 2

[0045] Example 2: Preparation of crude liraglutide

[0046] Add 2500ml of lysate to the liraglutide fully protected peptide resin obtained in Example 1, the proportions are TFA: 90%-95%, m-cresol: 1%-5%, EDT: 1%-5%, Purified water: 1-5%, cleavage at room temperature for 2-3 hours, suction filtration, add the filtrate to 10 times the volume of pre-cooled methyl tert-butyl ether to precipitate, centrifuge, and then wash the precipitate with methyl tert-butyl ether for 3 times, vacuum-dried to obtain liraglutide crude peptide.

Embodiment 3

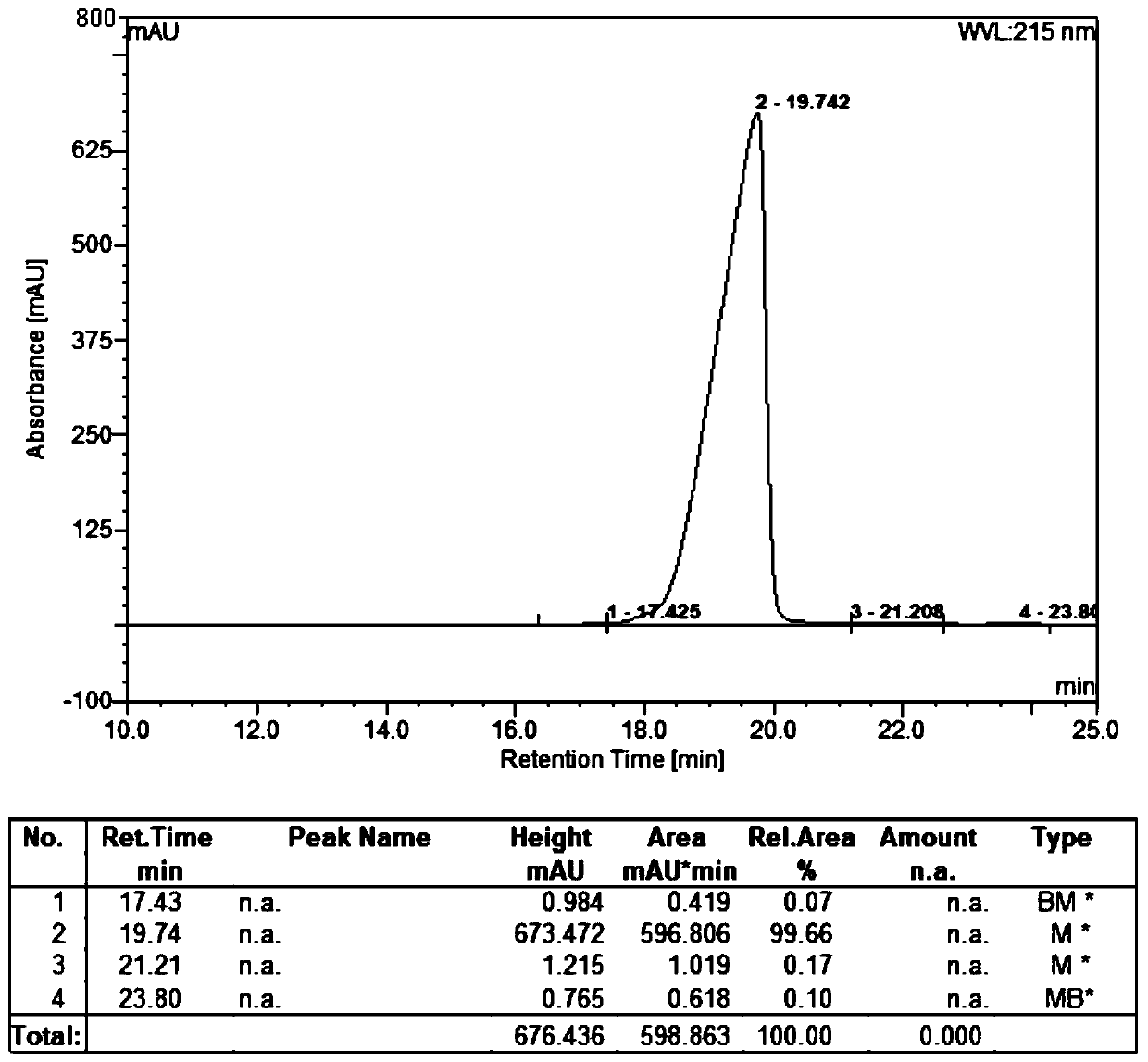

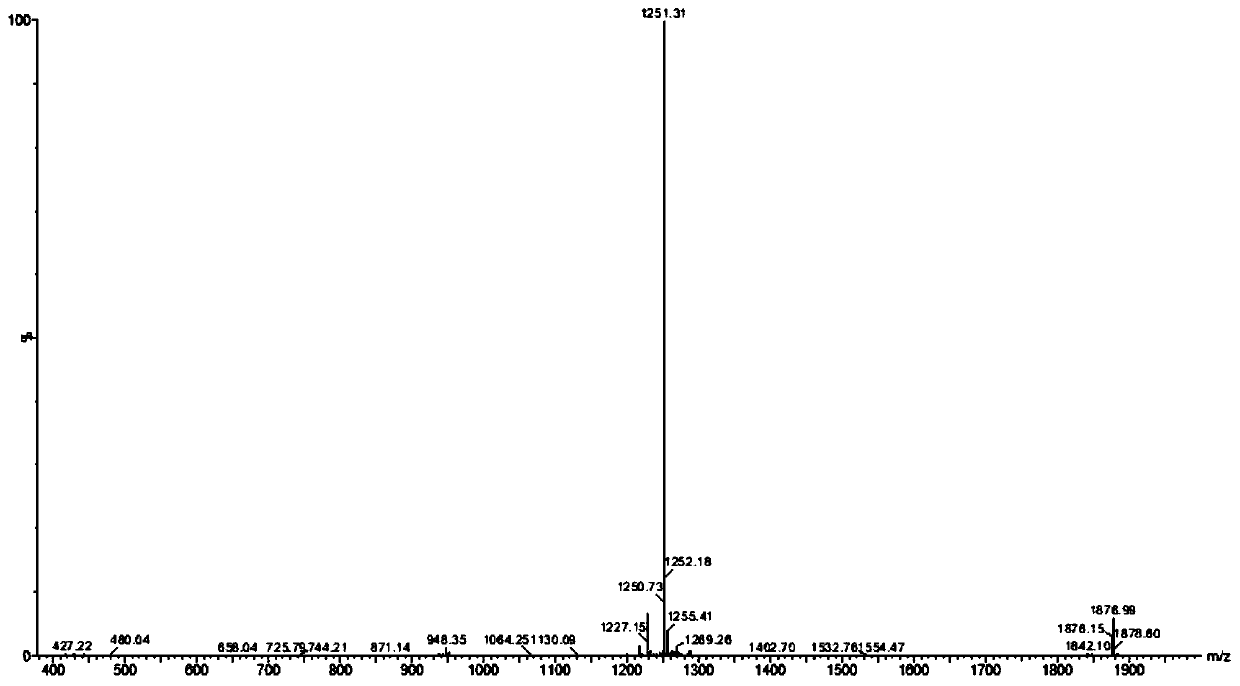

[0047] Example 3: Purification of Liraglutide Crude Peptide

[0048] The crude peptide was purified in two steps by reverse-phase high-performance liquid chromatography: the first step was purification, the mobile phase A was 20mmol / L sodium carbonate solution (pH was adjusted to 9 with phosphoric acid), and the B phase was: acetonitrile; the second step was purification For desalination of pure products, mobile phase A is purified water, and mobile phase B is ACN; the two-step purification is gradient elution, and the elution gradient: the first step is mobile phase B with 30% to 45%, nano-micro C18 packing ; The second step of purification and desalination is 10% to 50% of B phase, nano-micro C4 polymer filler, the elution time is 40min, and the ultraviolet detection wavelength is 220nm. The pure liraglutide was obtained by concentration and freeze-drying. The purity of liraglutide was tested to be 99.66%, the purity of the pure product was less than 0.15%, and the purifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com