Medical antibacterial plastic material and preparation method thereof

A technology of antibacterial plastics and composite antibacterial agents, which is applied in the field of medical antibacterial plastic materials and its preparation, can solve the problems of low friction coefficient and poor antibacterial effect of Teflon plastic, and achieve improved compatibility, safe and effective antibacterial effect, The effect of improving additional performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

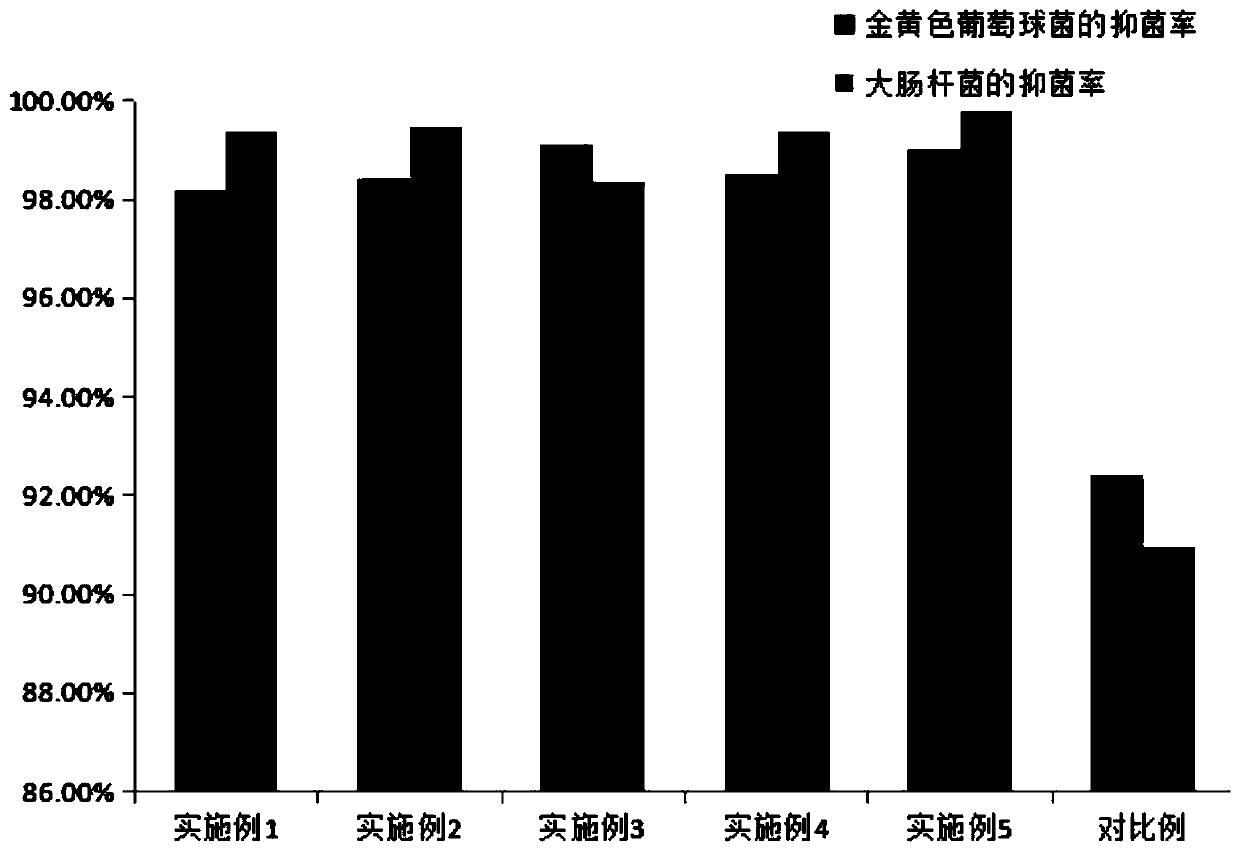

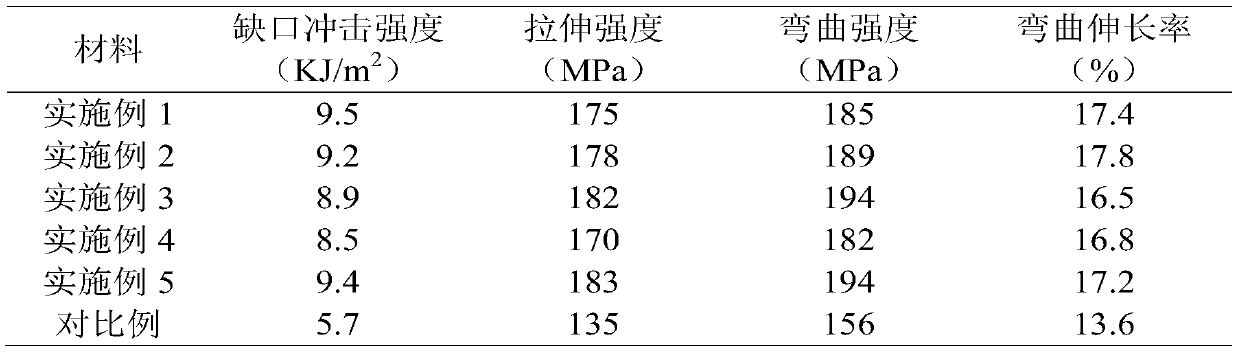

Examples

Embodiment 1

[0031] A kind of medical antibacterial plastic material and preparation method thereof

[0032] The raw materials for preparing medical antibacterial plastic materials include: 100kg of polypropylene, 5kg of low-density polyethylene, 5kg of ethylene-vinyl acetate copolymer, 0.4kg of polypropylene grafted carboxylic acid, 2.6kg of cedar oil, 2.4kg of epoxy soybean oil, compound Antibacterial agent 8kg, magnesium oxide 8kg, sodium stearate 3.0kg, antistatic agent 0.8kg; the melt flow rate of polypropylene (230 / 2.16kg) is 100g / 10min, and the density is 0.906G / cm 3 .

[0033] Wherein, composite antibacterial agent is prepared by the following method:

[0034] Step i, adding the chitosan of 8kg concentration is in the acetic acid solution of 30%, and the weight ratio of chitosan and acetic acid solution is 1:7, obtains premix;

[0035] Step ii, mixing 20 kg of nano-zinc oxide, 8 kg of nano-titanium oxide and 1.5 kg of shell powder to obtain a mixed powder; the shell powder is she...

Embodiment 2

[0043] A kind of medical antibacterial plastic material and preparation method thereof

[0044] The raw materials for preparing medical antibacterial plastic materials include: 100kg of polypropylene, 7kg of low-density polyethylene, 15kg of ethylene-vinyl acetate copolymer, 0.3kg of polypropylene grafted carboxylic acid, 2.2kg of cedar oil, 4.8kg of epoxy soybean oil, compound Antibacterial agent 6kg, magnesium oxide 4kg, sodium stearate 3.5kg, antistatic agent 1.0kg; the melt flow rate of polypropylene (230 / 2.16kg) is 100g / 10min, and the density is 0.906G / cm 3 .

[0045] Wherein, composite antibacterial agent is prepared by the following methods:

[0046] Step i, the chitosan of 10kg is joined in the acetic acid solution that concentration is 35%, and the weight ratio of chitosan and acetic acid solution is 1:8, obtains premix;

[0047] Step ii, mixing 10kg of nano-zinc oxide, 10kg of nano-titanium oxide and 1.2kg of shell powder to obtain a mixed powder; the shell powder is...

Embodiment 3

[0055] A kind of medical antibacterial plastic material and preparation method thereof

[0056] The raw materials for preparing medical antibacterial plastic materials include: 100kg of polypropylene, 10kg of low-density polyethylene, 12kg of ethylene-vinyl acetate copolymer, 0.8kg of polypropylene grafted carboxylic acid, 1.2kg of cedar oil, 2.8kg of epoxy soybean oil, compound Antibacterial agent 18kg, magnesium oxide 3kg, sodium stearate 1.5kg, antistatic agent 1.2kg; the melt flow rate of polypropylene (230 / 2.16kg) is 100g / 10min, and the density is 0.906G / cm 3 .

[0057] Wherein, composite antibacterial agent is prepared by the following methods:

[0058] Step i, the chitosan of 15kg is joined in the acetic acid solution that concentration is 25%, and the weight ratio of chitosan and acetic acid solution is 1:5, obtains premix;

[0059] Step ii, mixing 18 kg of nano-zinc oxide, 16 kg of nano-titanium oxide and 0.6 kg of shell powder to obtain a mixed powder; the shell po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow rate | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com