Zero-valent iron-loaded iron-manganese oxide composite material and preparation method and application thereof

A technology of iron-manganese oxides and composite materials, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problem of low efficiency of active oxygen species, low efficiency, Unable to fully activate persulfate and other problems, to achieve the effects of enhanced pollutant degradation and removal, high reducibility, and uniform solid particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

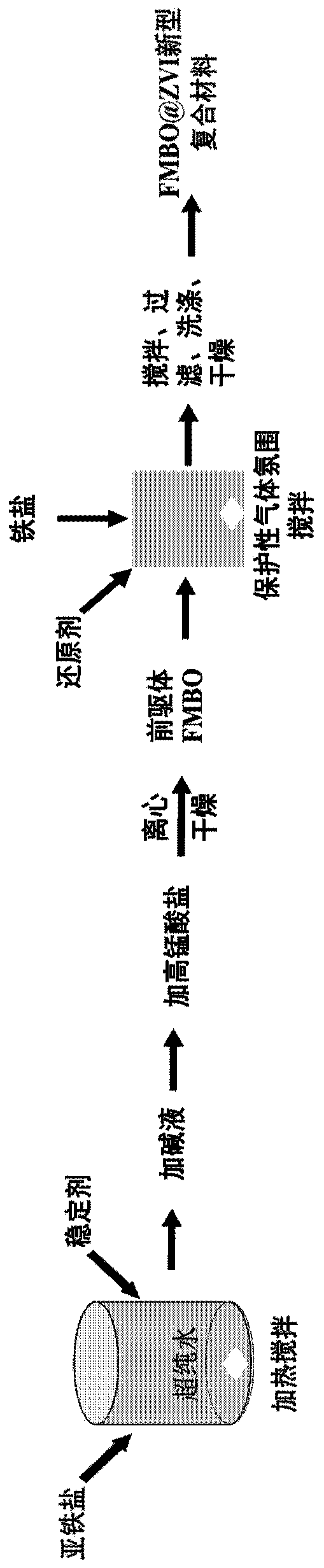

[0019] figure 1 It is a schematic diagram of the preparation process of the FMBO@ZVI composite material of the present invention. like figure 1 As shown, the present invention discloses a preparation method of a zero-valent iron-loaded iron-manganese oxide composite material (FMBO@ZVI), and the steps are as follows:

[0020] (1) mixing and dissolving ferrous salt and stabilizer, adding alkaline solution under stirring to generate flocculent precipitation;

[0021] (2) adding permanganate solution to the flocculent precipitate obtained in step (1), reacting to obtain precipitation, and obtaining iron-manganese oxide precursor after separation and cleaning;

[0022] (3) in protective atmosphere, iron salt and dispersant are dissolved in the container that ethanol / water mixed solution is housed, adjust pH to a certain range;

[0023] (4) adding the iron-manganese oxide precursor prepared in step (2) to the mixture obtained in step (3), in a protective atmosphere, adding a cert...

Embodiment 1

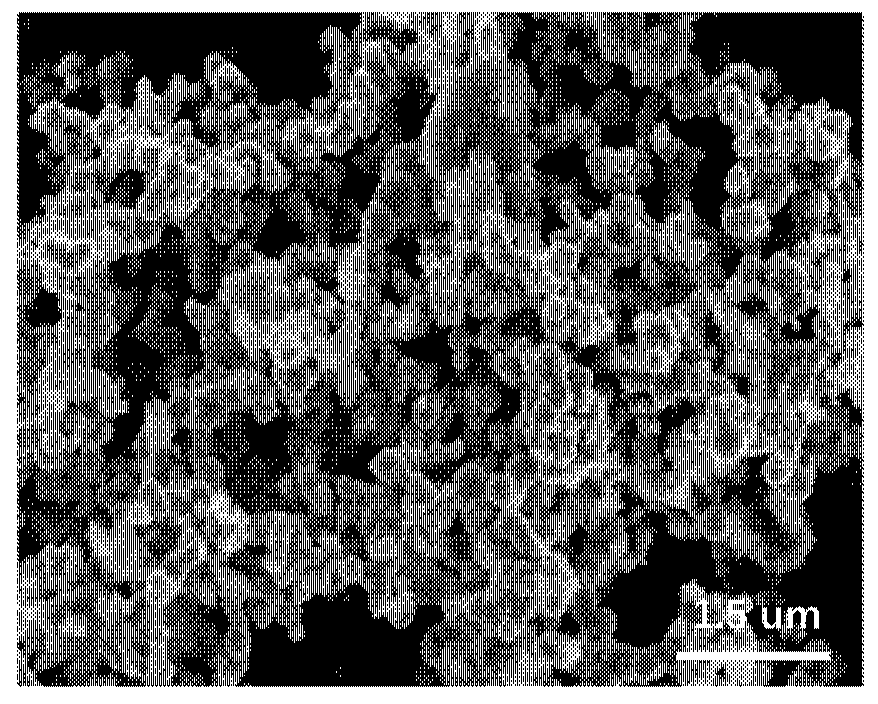

[0057] The present embodiment adopts the simple and feasible chemical co-precipitation synthesis method to prepare FMBO material, wherein the molar ratio of iron and manganese is 4.5: 1, and the specific operation is as follows:

[0058] First, 0.045mol FeSO 4 ·7H 2 O and 9g of polyvinylpyrrolidone (PVP) were dissolved in 900mL of water and heated to 90°C, then 18mL of 5M NaOH solution was added dropwise under magnetic stirring, and dark green Fe(OH) was formed in the solution. 2 Precipitate, add 10mL, 1M KMnO after 5min 4 The solution was left to stand for 12h and a dark brown precipitate was formed. After the mixed liquid was cooled to room temperature, it was centrifugally filtered, washed with ultrapure water and ethanol three times, freeze-dried, ground and sieved to obtain F. 4.5 M 1 Powder of BO.

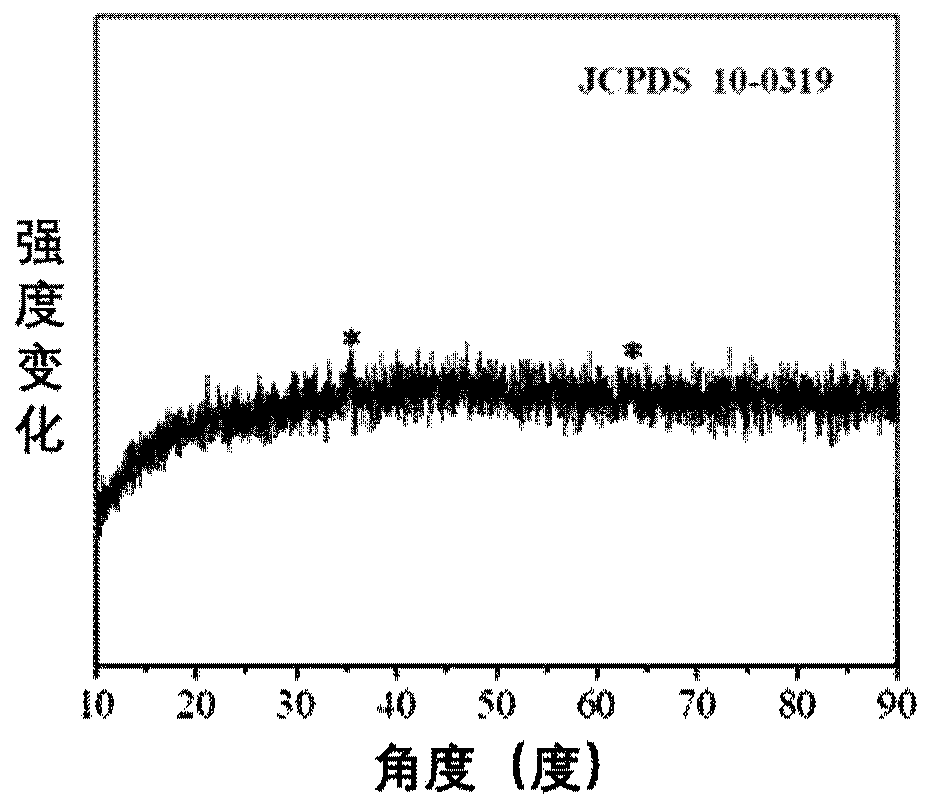

[0059] F in this example 4.5 M 1 BO@ZVI composites are made by F 4.5 M 1 The adsorption ability of the BO precursor can convert FeSO 4 ·7H 2 The O solution adsorbe...

Embodiment 2

[0065] The preparation method is the same as that in Example 1, except that the molar ratio of iron and manganese is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com