Rib cavity protection method for welding of U-shaped rib of titanium alloy frame vehicle body

A titanium alloy, U-shaped technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of inability to protect air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

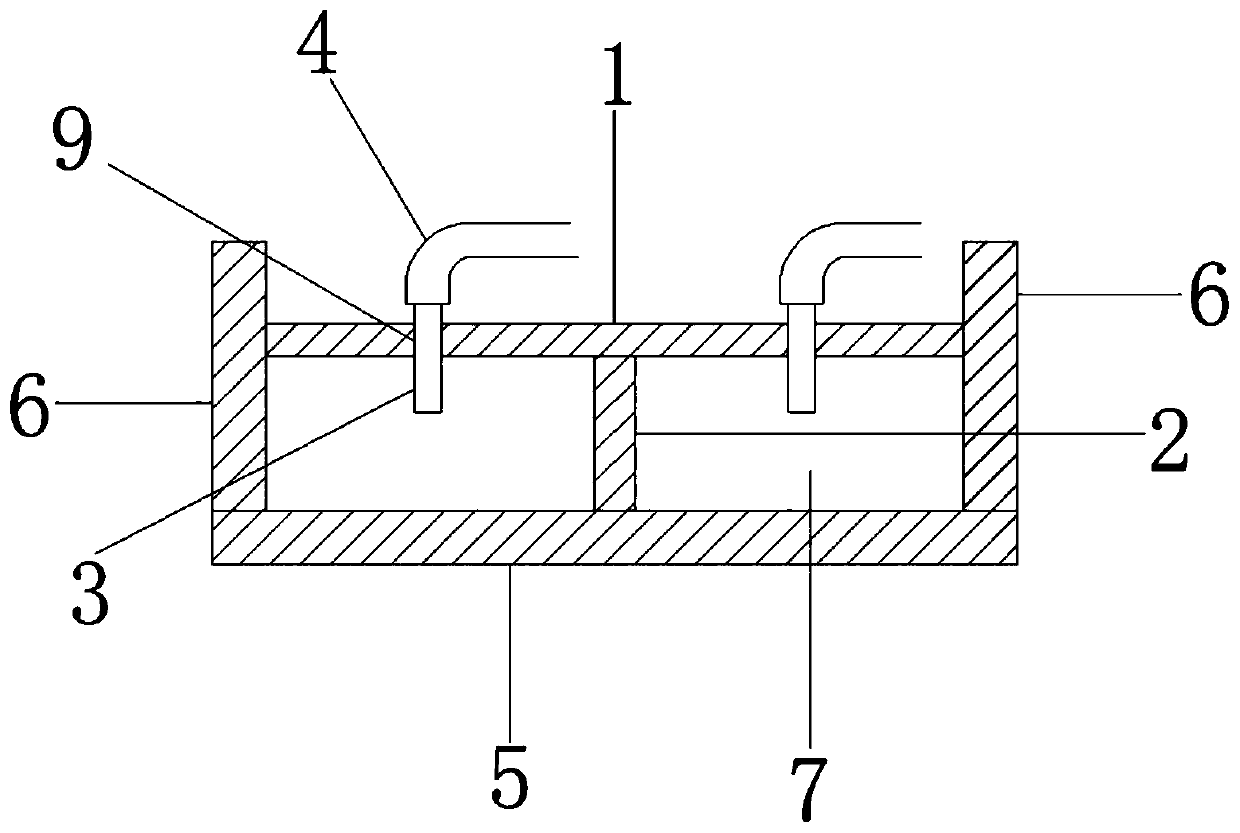

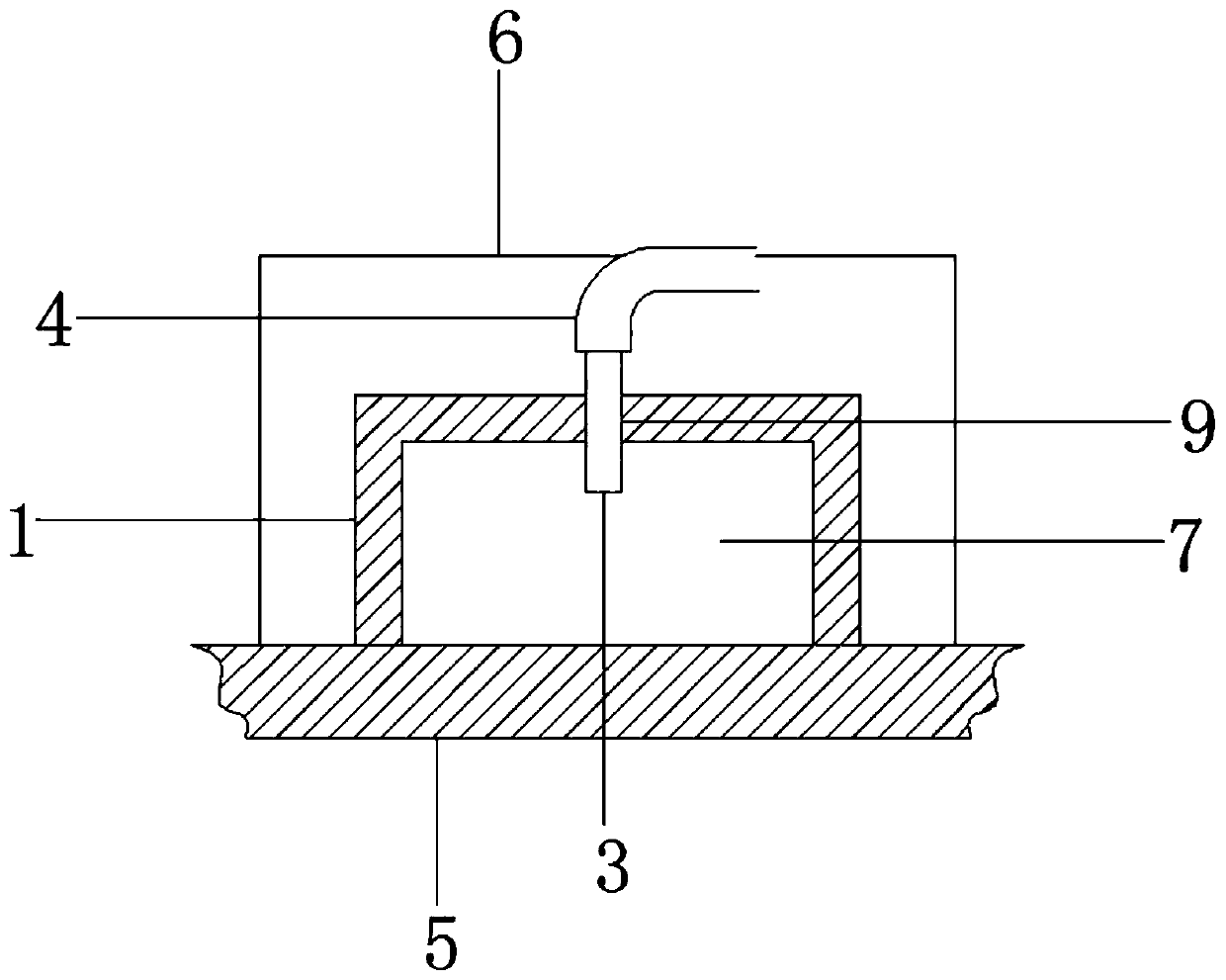

[0021] A rib cavity protection method for U-shaped rib welding of a titanium alloy frame car body. Firstly, a process hole 9 is arranged on the upper surface of the U-shaped rib 1, and then the U-shaped rib 1 is fitted to the surface of the deck 5 and the side plate 6 to form an extrusion Cavity 7, and control the gap formed by lamination should be <3mm, then fill the argon gas from the process hole 9 into the extrusion cavity 7 to squeeze out the air, after the air is squeezed out from the extrusion cavity 7, start Arc welding U-shaped rib 1 and deck 5, U-shaped rib 1 and side plate 6.

[0022] The number of process holes 9 arranged on the U-shaped bar 1 is determined according to the length of the welded U-shaped bar 1. When the length of the U-shaped bar 1<400mm, drill a process hole 9; when 400mm≤U-shaped bar 1 length<800mm, Set two process holes 9 symmetrically with the left and right symmetry lines of the U-shaped rib 1 as the symmetrical axis, and the distance between t...

Embodiment 2

[0030] A rib cavity protection method for welding U-shaped ribs of a titanium alloy frame car body First, a process hole 9 is provided on the upper surface of the U-shaped rib 1, and then the U-shaped rib 1 is fitted with the surface of the deck 5 and the side plate 6 to form an extrusion cavity 7, and control the gap formed by lamination should be <3mm, then fill the argon gas from the process hole 9 into the extrusion chamber 7 to squeeze out the air, after the air is squeezed out from the extrusion chamber 7, start to work Arc welding U-shaped rib 1 and deck 5, U-shaped rib 1 and side plate 6.

[0031] The number of process holes 9 arranged on the U-shaped bar 1 is determined according to the length of the welded U-shaped bar 1. When the length of the U-shaped bar 1<400mm, drill a process hole 9; when 400mm≤U-shaped bar 1 length<800mm, Set two process holes 9 symmetrically with the left and right symmetry lines of the U-shaped rib 1 as the symmetrical axis, and the distance...

Embodiment 3

[0039] A rib cavity protection method for U-shaped rib welding of a titanium alloy frame car body. Firstly, a process hole 9 is arranged on the upper surface of the U-shaped rib 1, and then the U-shaped rib 1 is fitted to the surface of the deck 5 and the side plate 6 to form an extrusion Cavity 7, and control the gap formed by lamination should be <3mm, then fill the argon gas from the process hole 9 into the extrusion cavity 7 to squeeze out the air, after the air is squeezed out from the extrusion cavity 7, start Arc welding U-shaped rib 1 and deck 5, U-shaped rib 1 and side plate 6.

[0040] The number of process holes 9 arranged on the U-shaped bar 1 is determined according to the length of the welded U-shaped bar 1. When the length of the U-shaped bar 1<400mm, drill a process hole 9; when 400mm≤U-shaped bar 1 length<800mm, Set two process holes 9 symmetrically with the left and right symmetry lines of the U-shaped rib 1 as the symmetrical axis, and the distance between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com