Bio-based composite material film and rice brick bag made of bio-based composite material film

A composite material film and composite material technology, which is applied to the types of packaging items, special packaging items, synthetic resin layered products, etc., can solve the problems of petroleum-based resource waste environment, intolerance to humid environment, poor air permeability of products, etc., and achieve the appearance Exquisite, low price, convenient processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following examples.

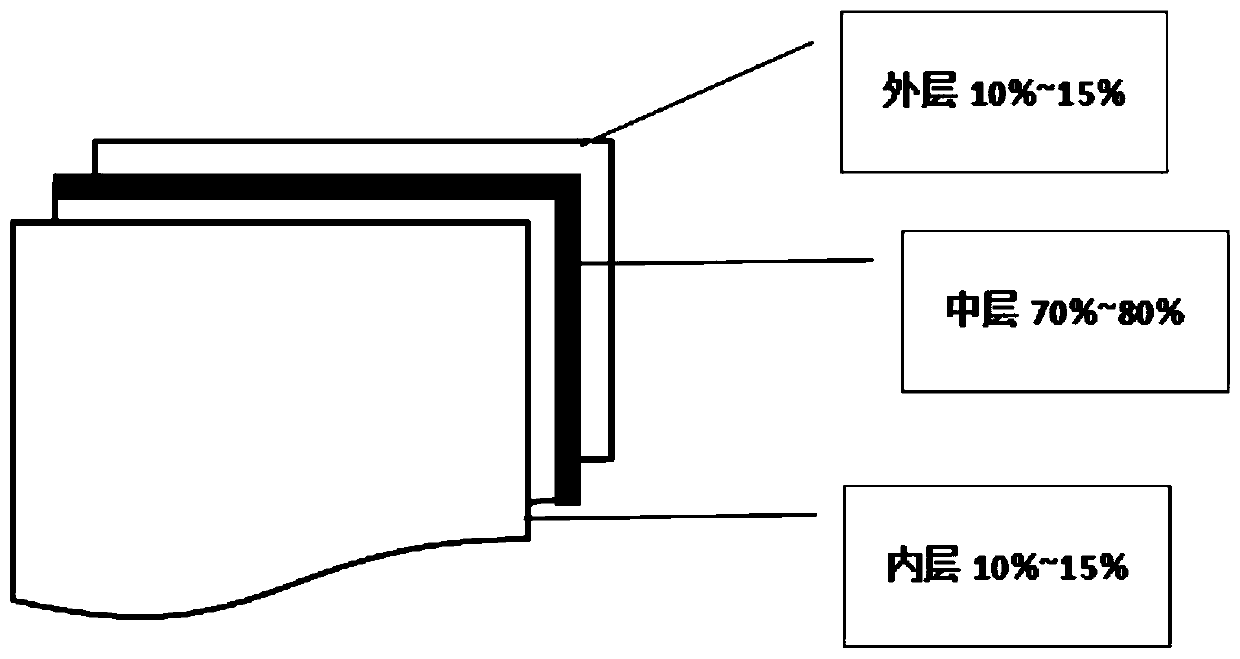

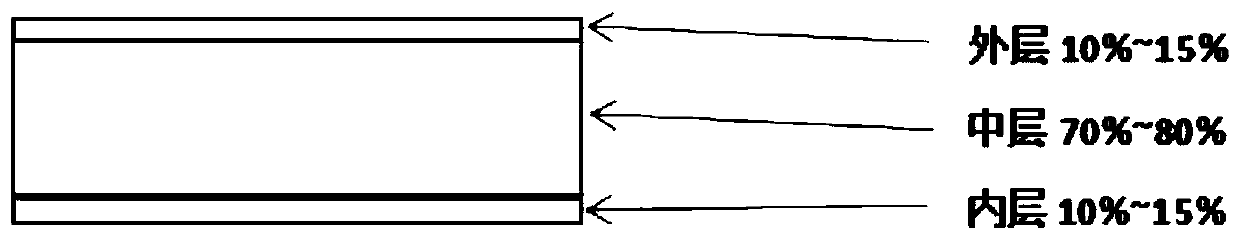

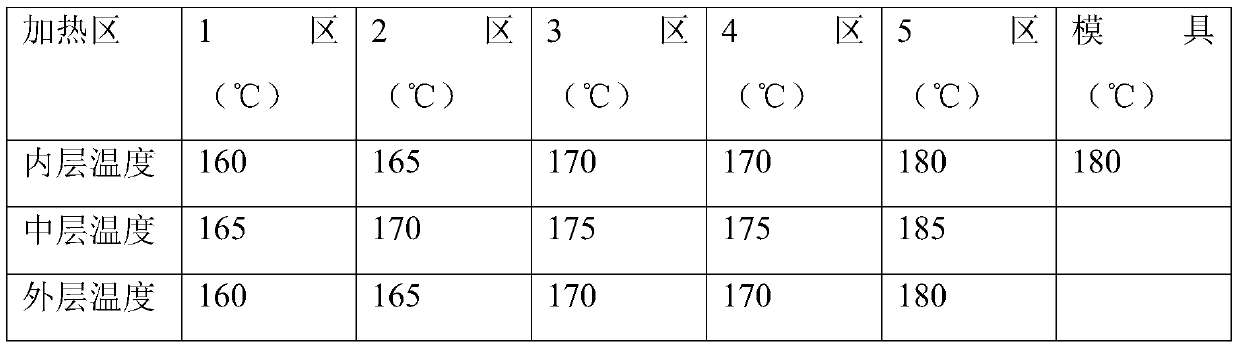

[0016] Such as figure 1 , figure 2 As shown, a bio-based composite material film involved in this embodiment includes three layers of materials with different components, and its structure is as follows figure 1 As shown, the material is made of three layers of materials with different components from the inside to the outside, and is processed by a DW-3L-850 (A+B+C) three-layer co-extrusion blown film machine; DW-3L-850 (A +B+C) type three-layer co-extrusion film blowing machine is composed of three extruders, control system, rotary film blowing head, abrasive tools, heating system, traction and curling system, which can ensure that the film products have strict The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com