Application of oxidized konjac microspheres to food or drug delivery system

A technology of microspheres and food, which is applied in the biological field and can solve problems that need to be studied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

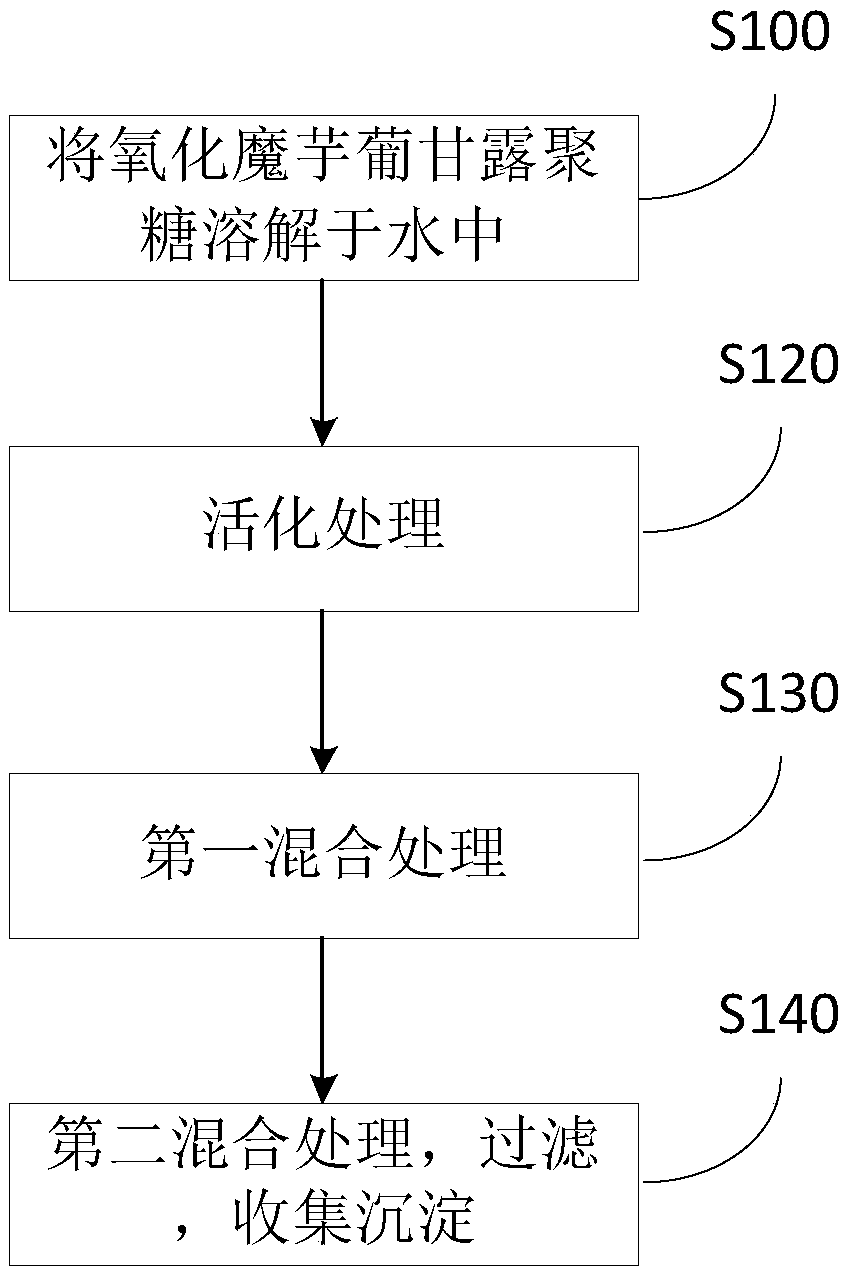

[0119] In this example, sulfhydryl-modified oxidized konjac glucomannan OKGM-Cys was prepared according to the following method:

[0120] Weigh 3 parts of 100mg oxidized konjac glucomannan and dissolve them in 20mL of ultrapure water respectively. After the oxidized glucomannan is completely dissolved, add 0.083g of EDC [1-(3-dimethylaminopropyl)- 3-Ethylcarbodiimide hydrochloride] Activated for 1 hour, then added 0.038 g of cysteine hydrochloride, and reacted on a magnetic stirrer at room temperature for 24 hours, during which nitrogen gas was introduced to remove oxygen.

[0121] The product was precipitated with an equal volume of ethanol, filtered, and the precipitate was washed 3 times with ethanol to remove EDC and unreacted cysteine hydrochloride to obtain precipitated OKGM-Cys. Reconstitute the precipitate with 10 mL of ultrapure water, and stir at room temperature for 2 h until no visible white particles are seen, which can be considered as complete dissolution of...

Embodiment 2

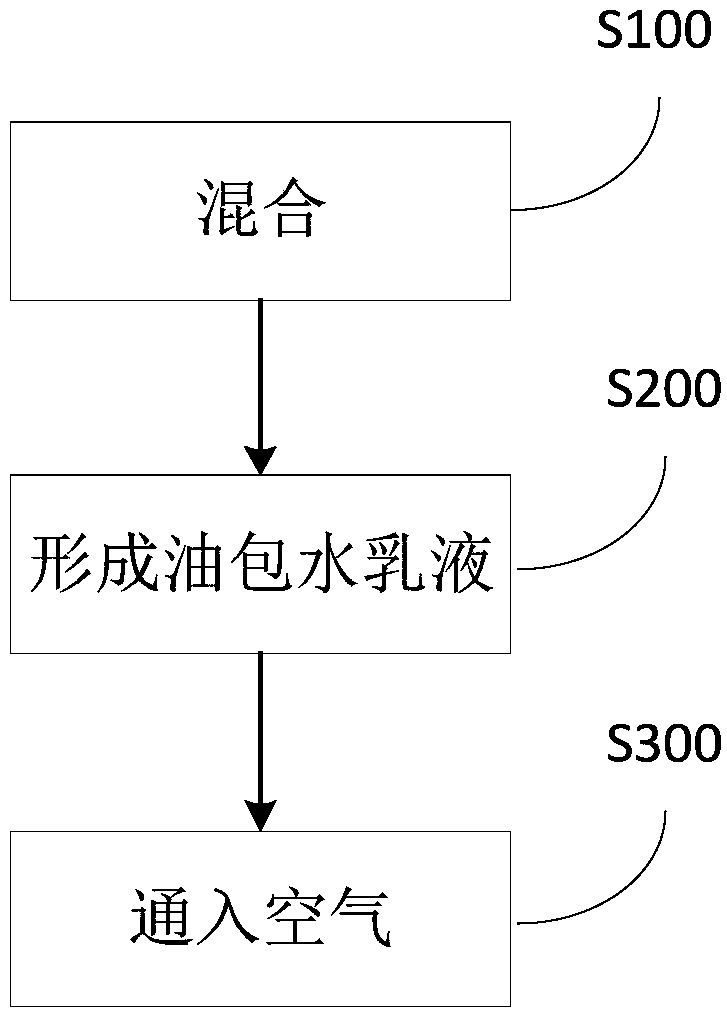

[0123] In this example, microsphere carriers were prepared as follows:

[0124] Take 50 mg of the thiol-modified oxidized konjac glucomannan powder prepared in Example 1 and 6 mg of ferrous sulfate heptahydrate and dissolve them in 500 microliters of deionized water. After the powder is completely dissolved, dissolve 0.75 g of span 80 into 20 g of paraffin oil In, stir well. The water phase is gradually added to the oil phase under mild conditions to form a water-in-oil emulsion. Under the condition of a water bath at 35°C, air was gradually pumped into the emulsion, and at the same time, it was stirred at a speed of 500 rpm under a magnetic stirrer for 4 hours. After 4 hours, under the centrifugation condition of 3000 rpm and 2 min, the microparticles were washed with n-hexane for 3 times, and the microparticles were washed with methanol for 3 times. The microsphere precipitate washed in the last step was dissolved in 2 mL of ultrapure water with pH 3, and the sample was st...

Embodiment 3

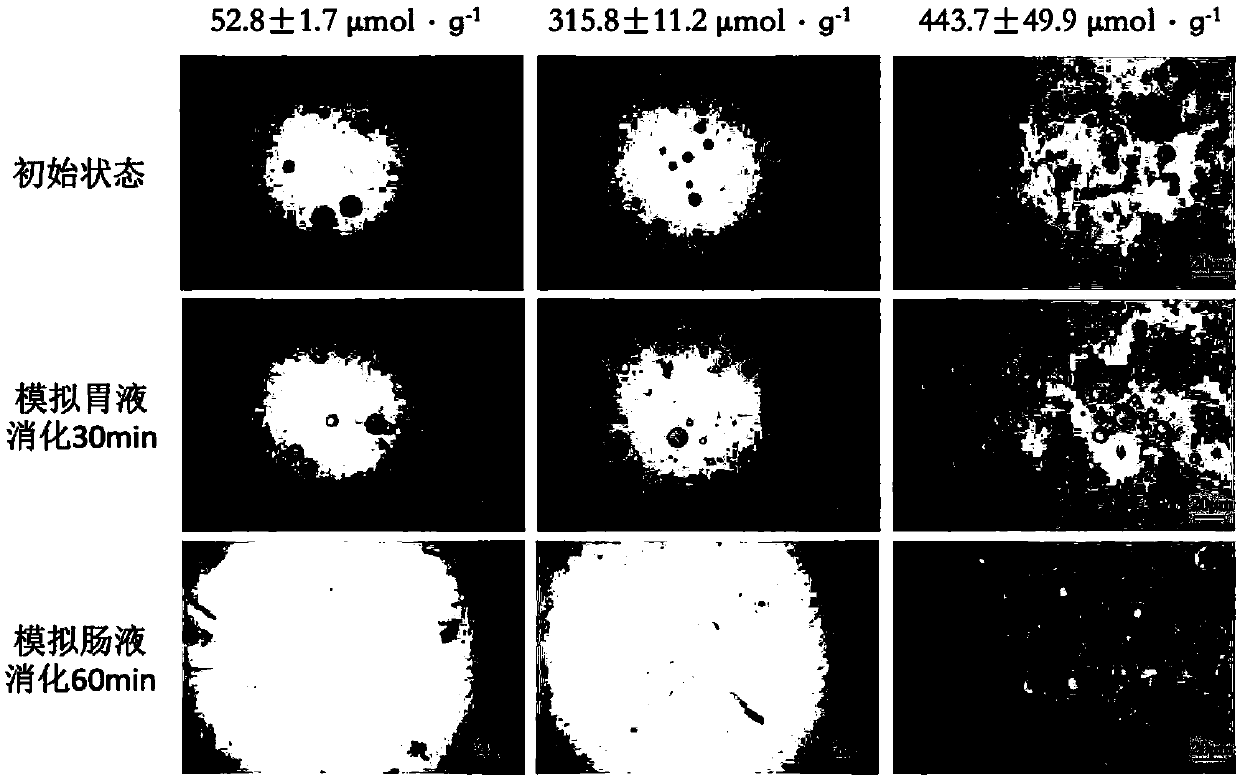

[0130] To characterize the stability of the microsphere carrier obtained in Example 2, Comparative Examples 1 and 2 under simulated gastrointestinal fluid in vitro, the specific steps are as follows:

[0131] Dissolve 1 g of pepsin in 90 mL of ultrapure water, adjust the pH of the solution to 1.2 with hydrochloric acid solution, and set the volume to 100 mL to obtain 1% (w / v) simulated gastric juice; take 0.68 g of potassium dihydrogen phosphate, add Dissolve it in 50 mL of ultrapure water, adjust the pH of the solution to 6.8 with 0.5 mol / L sodium hydroxide, add 1 g of trypsin, and dilute to 100 mL to obtain 1% (w / v) simulated intestinal juice.

[0132] Take 100 μL of the three kinds of OKGM-Cys thiolated oxidized konjac glucomannan microspheres prepared above and add them to 400 μL of simulated gastric juice, and digest them in a water bath at 37°C for 30 min; Glucomannan microspheres were added to 400 μL of simulated intestinal fluid, and digested in a water bath at 37°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com