High-GABA low-caffeine black tea melts and a preparation method thereof

A technology of low caffeine black tea and its production method, which is applied in the field of high GABA and low caffeine black tea soluble beans and its production, can solve the problems of no high gamma-aminobutyric acid, low caffeine, reduced gamma-aminobutyric acid content, etc. Achieve the effect of strong product, strong tea fragrance and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

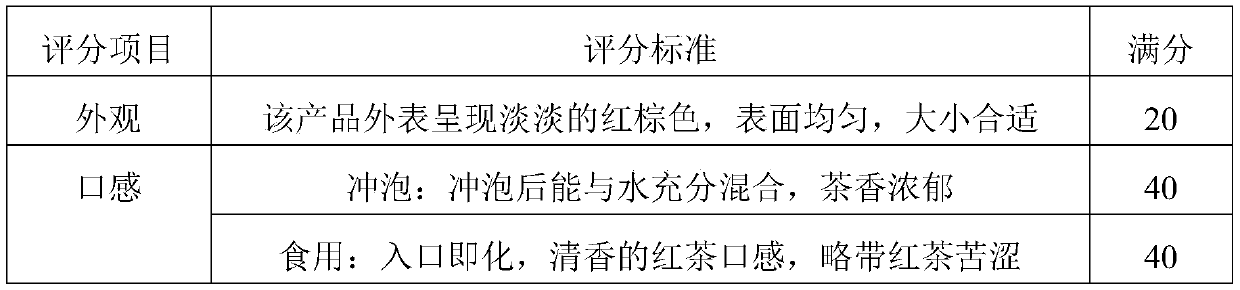

Examples

Embodiment 1

[0047] The preparation method of black tea soluble beans 1 with high GABA and low caffeine comprises the following steps:

[0048] 1) Black tea concentrate:

[0049] a. Production of high GABA black tea: Soak the fresh black tea leaves with 2% glutamic acid aqueous solution for 1 hour under infrared light irradiation, wash them, wither naturally, knead the tea leaves for 70 minutes, transfer them to the fermentation room for fermentation for 4 hours, and spread them thick, dried high GABA black tea;

[0050] b. Decaffeination: soak the crushed black tea in salt water for 30 minutes, drain, transfer to the extraction kettle raised by supercritical fluid extraction, and crush the crushed black tea under the conditions of 28Mpa, pressure 45°C, and flow rate of 15L / min. The tea is subjected to circular extraction, and after extraction for 2 hours, the broken black tea is taken out;

[0051] c. Preparation of black tea concentrate: mix the tea leaves treated in step b with water an...

Embodiment 2

[0058] The method of the black tea soluble bean 2 with high GABA and low caffeine that the present embodiment makes is basically the same as the method in Example 1; the difference is:

[0059] Black tea soluble beans 2 with high GABA and low caffeine consist of the following components by weight:

[0060] 80 parts of black tea concentrate, 3 parts of concentrated strawberry juice, 5 parts of barley starch, 5 parts of corn starch, 5 parts of purple potato starch, 8 parts of β-cyclodextrin, 10 parts of locust bean gum, 6 parts of 1 part D-erythorbic acid and 3 parts B vitamins 12 .

Embodiment 3

[0062] The method of the black tea soluble bean 3 with high GABA and low caffeine that the present embodiment makes is basically the same as the method in Example 1; the difference is:

[0063] High GABA and low caffeine black tea soluble beans 3 consist of the following components by weight:

[0064] 80 parts of black tea concentrate, 3 parts of concentrated tomato juice, 5 parts of barley starch, 5 parts of corn starch, 5 parts of purple potato starch, 8 parts of β-cyclodextrin, 10 parts of locust bean gum, 6 parts of D-erythorbic acid, 3 parts of vitamin B 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com